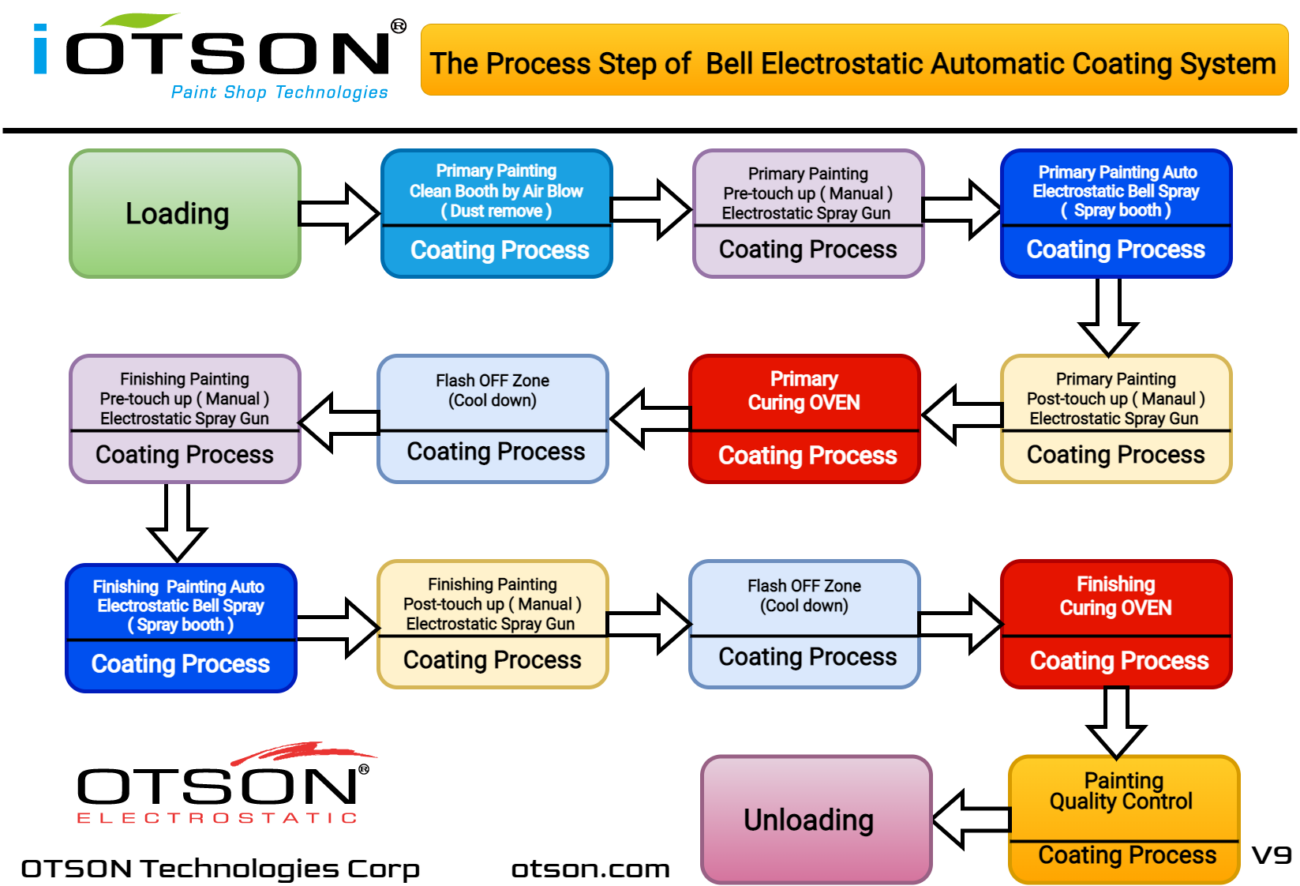

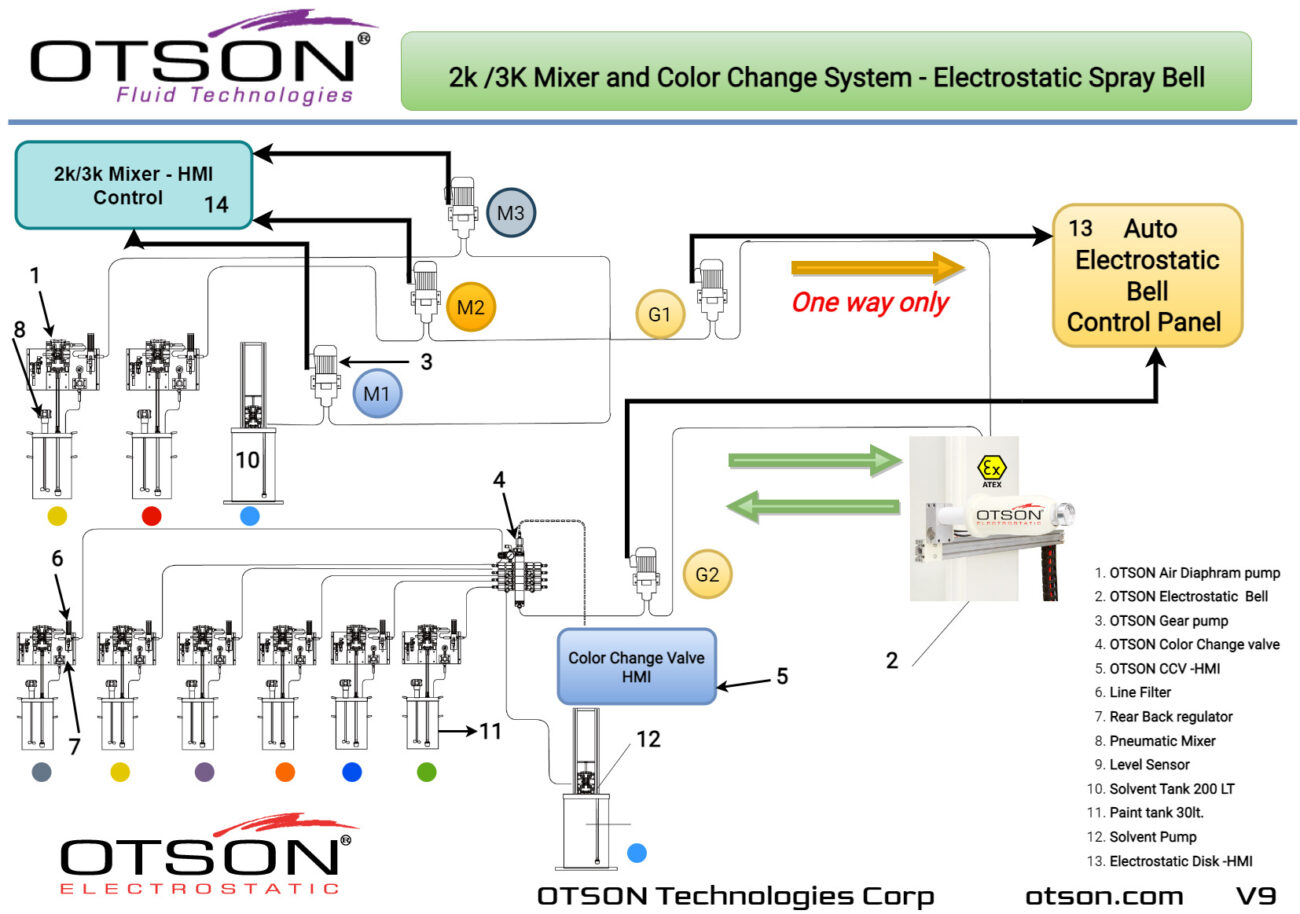

The Auto Color Change System is a technical solution for liquid electrostatic spray equipment, such as auto electrostatic spray bell, auto electrostatic spray disc, and auto electrostatic spray gun. This system is designed to provide rapid and accurate color changes for spray equipment in industrial applications, including automotive, aerospace, and other manufacturing processes.

The Auto Color Change System utilizes a series of valves and pumps to control the flow of paint and the color change process. The system is fully automated, reducing the need for manual intervention and streamlining the painting process. This makes it possible to change colors quickly and accurately, resulting in improved productivity and reduced waste.

Here are some of the key features of the Auto Color Change System:

- Fast and Accurate Color Changes: The system is designed for rapid and accurate color changes, allowing for improved productivity and reduced downtime.

- Fully Automated: The Auto Color Change System is fully automated, minimizing the need for manual intervention and streamlining the painting process.

- Versatile: The system is compatible with a wide range of paint types, including solvent-based and water-based paints, making it adaptable to various industrial applications.

- Programmable: The user-friendly interface and controls make it easy to program and operate, allowing for quick and seamless color changes.

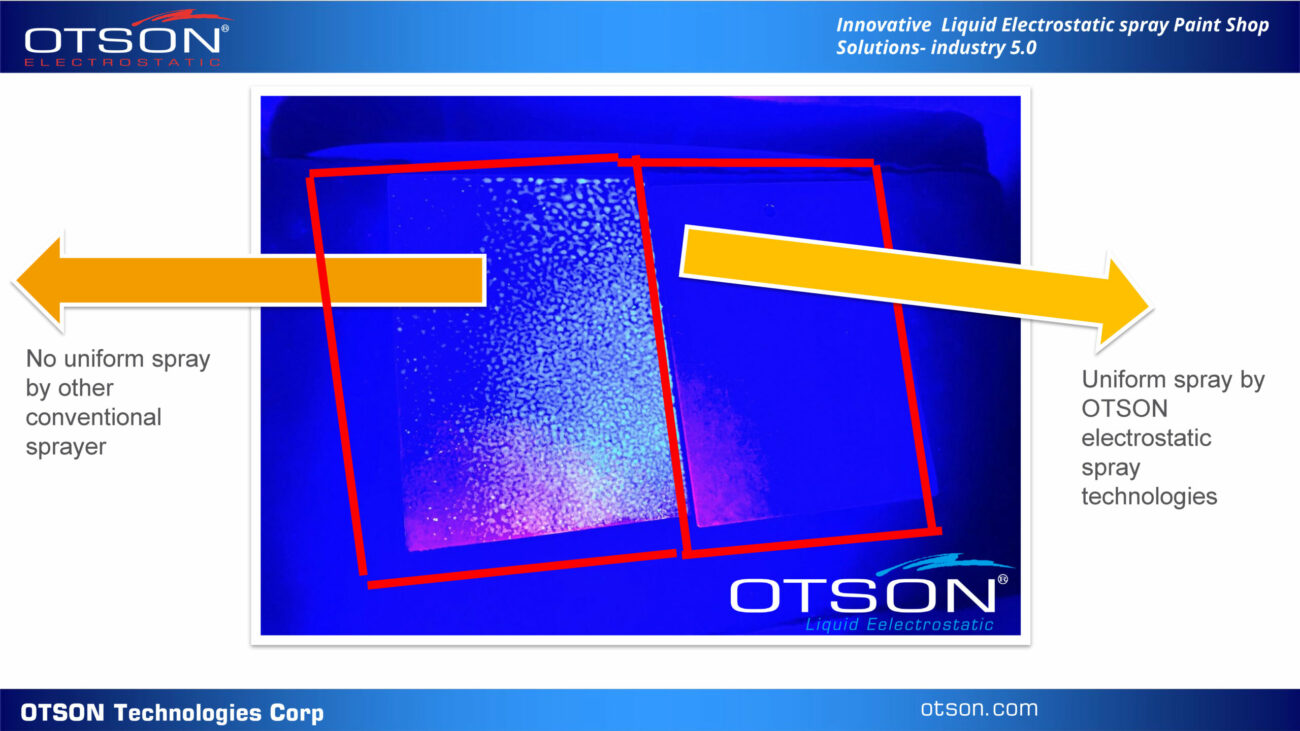

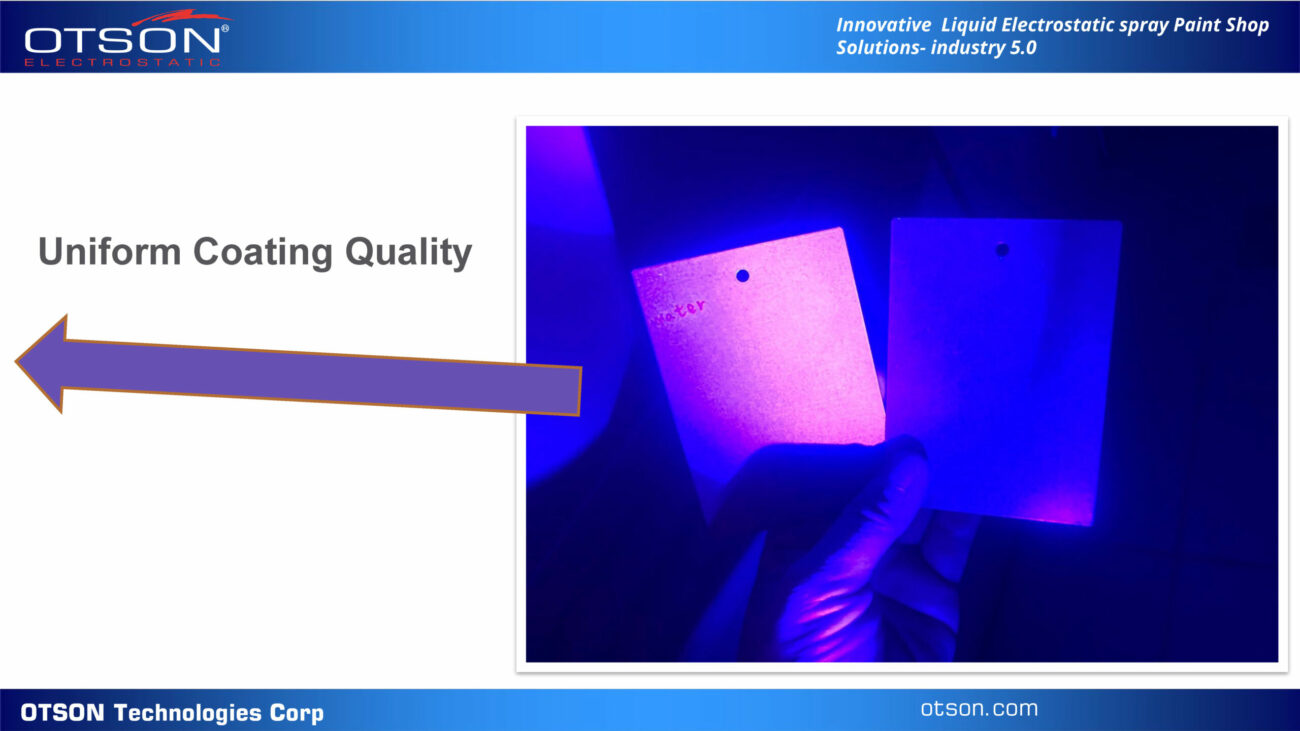

- High-Quality Finishes: The Auto Color Change System enables the application of a consistent and high-quality finish, improving the overall quality of the paint job.

- Customizable: The system can be customized to handle a range of color changes, from two to twenty or more, depending on the specific needs of the application.

- Efficient: The system reduces waste and cleanup time, making it an efficient solution for industrial painting processes.

- Reliable: The Auto Color Change System is designed to be reliable and long-lasting, ensuring consistent performance over time.

In conclusion, the Auto Color Change System for liquid electrostatic spray equipment provides a technical solution for efficient and accurate color changes. It is an essential component of industrial painting processes, providing high-quality finishes and improving productivity while reducing waste. The system is versatile, compatible with a range of paint types, and can be customized to meet the specific needs of any industrial application. With its fully automated and programmable features, the Auto Color Change System offers a reliable and efficient solution for liquid electrostatic spray equipment.

Color change valves, also known as paint dispensers, are a valuable investment for any business in the painting industry. These devices are used in paint shops to mix and dispense paint quickly and accurately, reducing waste and cleanup time.

One of the key benefits of a color change valve is its ability to automatically switch between different paint colors, which can save time and increase efficiency. This feature is especially useful for businesses that work on multiple projects and need to switch between colors frequently.

Another advantage of color change valves is their mixing capabilities. These devices can mix the paint with hardeners, reducers, or other additives as it is dispensed, ensuring that the paint is properly mixed and ready to use, which can help improve the quality of the paint job.

In terms of market view, the use of color change valves is prevalent in industrial paint application such as automotive, aerospace, and wood finishing industries. Many companies are investing in color change valves to improve their production efficiency and reduce cost.

Overall, color change valves are an essential component of any paint shop, providing accurate and efficient paint dispensing and color change capabilities. Investing in a high-quality color change valve can help businesses in the painting industry to increase productivity, improve the quality of their paint jobs and save money in the long run.

At OTSON Technologies Corp, we understand the importance of having the right equipment for your paint shop. That’s why we offer advanced color change valves that are designed to meet the specific needs of your paint shop. Our color change valves are known for their efficiency, accuracy, and durability.

Our color change valves offer a range of features including:

- Automatic color change: Allows for quick and easy switching between different paint colors, which can save time and increase efficiency.

- Mixing capabilities: Can mix the paint with hardeners, reducers, or other additives as it is dispensed, ensuring that the paint is properly mixed and ready to use.

- Flow rate control: Allows you to set and monitor the flow rate of the paint, ensuring that the right amount of paint is dispensed for each job.

- Multiple paint tanks: Some color change valves can be equipped with multiple paint tanks for storing different colors of paint, making it easy to switch between colors.

- Easy to clean: Many color change valves are designed to be easy to clean, which can save time and reduce cleanup costs.

- Durable and long-lasting: High-quality color change valves are built to last, with durable components that can withstand the demands of a paint shop environment.

- Remote control: Some color change valves can be controlled remotely, allowing you to make adjustments or switch colors from a distance.

- Data logging: Some color change valves can record data such as paint usage, color changes, and flow rate, which can be used to track performance and make adjustments as needed.

- Compatibility: Some color change valves are compatible with a wide range of paint application equipment, such as spray guns, rollers, and brushes.

- Safety features: Our color change valves are equipped with fire detection sensors and emergency stop buttons for added safety.

- ATEX equipment for explosion-proofing.

- Industry 5.0 compatibility for easy integration with other equipment and systems in the paint shop.

- Low VOC emissions, which helps to reduce air pollution and improve the overall environmental impact of the paint shop.

Our team of experts provides training and support to help you get the most out of your color change valves, and we’re committed to helping you optimize your paint shop for maximum efficiency and productivity. Contact us today to learn more about how we can help meet your specific needs and requirements.