OTSON is a leading provider of liquid and powder electrostatic spray technologies, as well as fluid transfer technologies for the industrial and commercial markets. Our cutting-edge technology and patented designs are backed by our team of experts who are available to assist with integration and optimization of these solutions in your specific processes. With ATEX certification, we are able to deliver high-quality finishes, reduce paint waste, and increase production rates, ultimately leading to a higher return on investment (ROI) for your business.

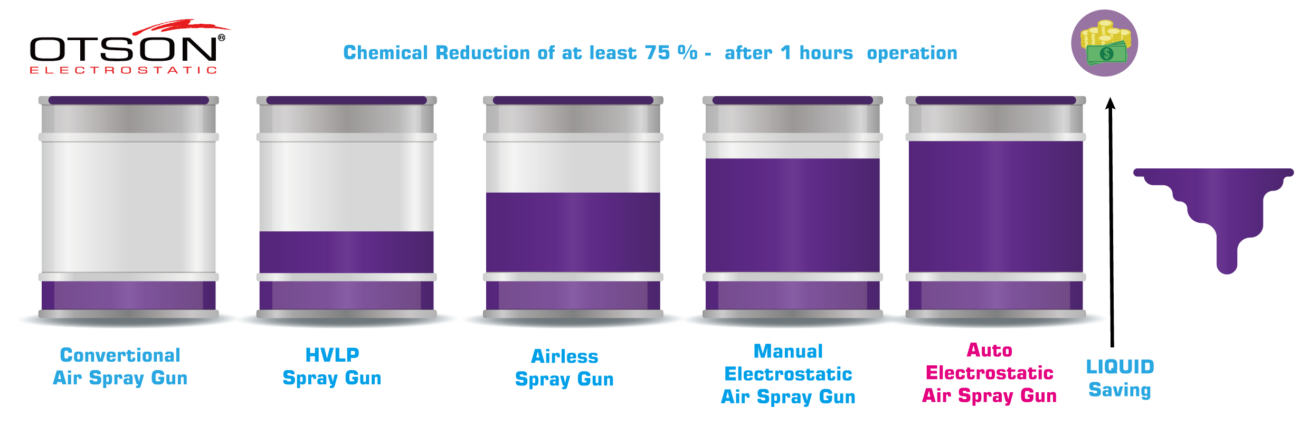

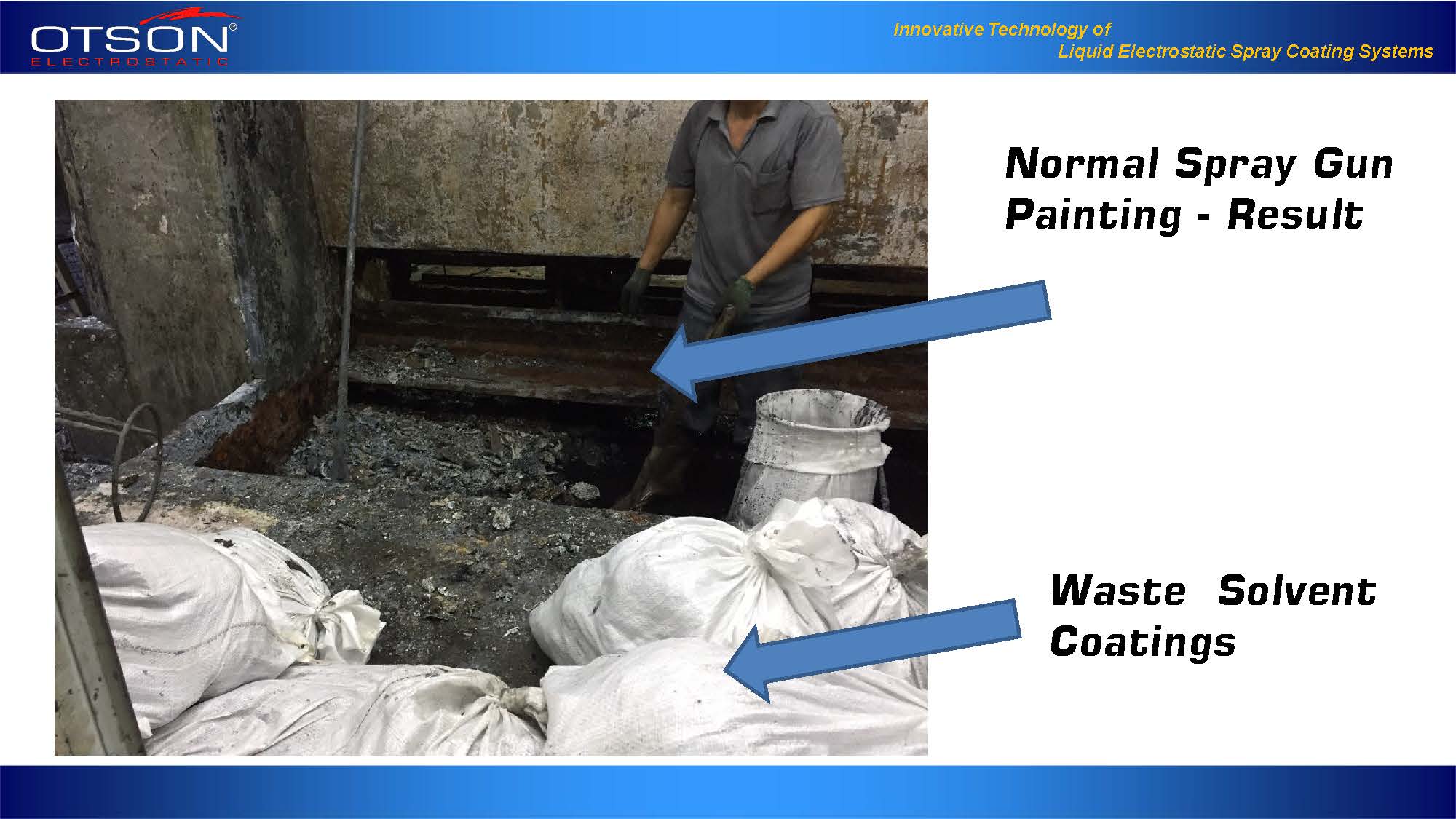

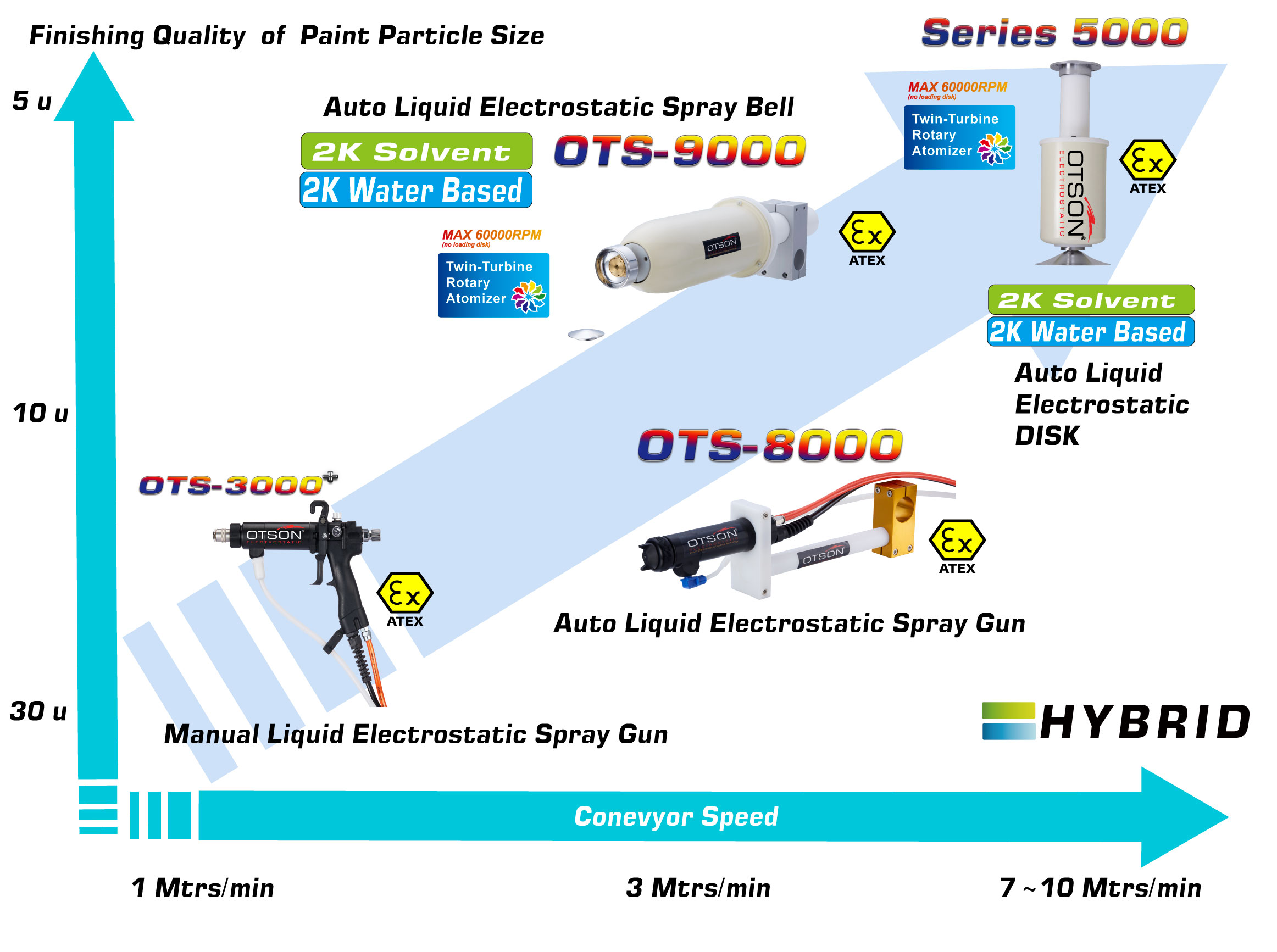

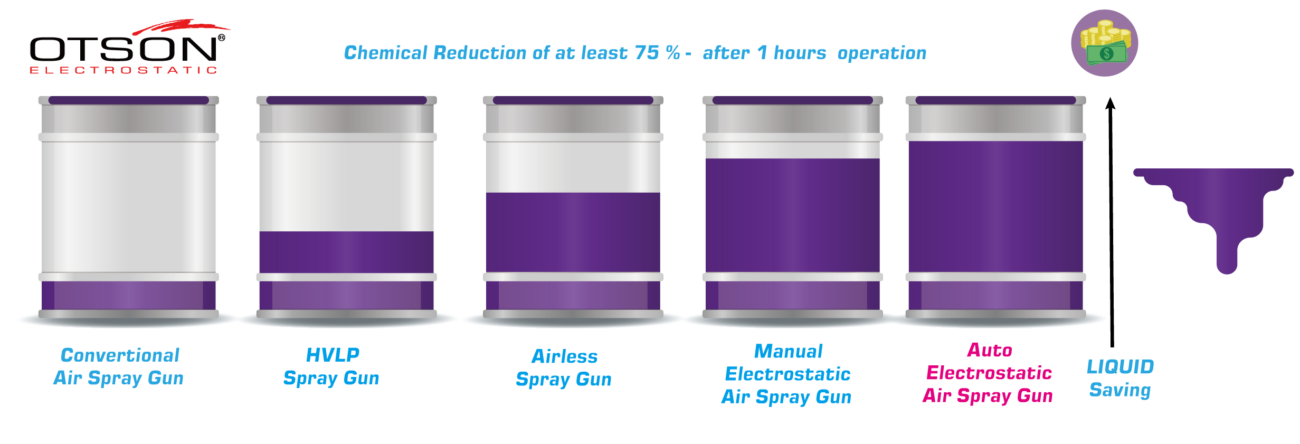

The electrostatic spray technology market is expected to grow significantly in the coming years, driven by increasing demand for efficient and eco-friendly coating methods across various industries. OTSONs electrostatic spray systems are well-positioned to take advantage of this trend, offering cost-saving and quality-enhancing benefits for customers. Compared to traditional coating methods, our systems can help customers to cut paint costs by up to 50% and improve production output.

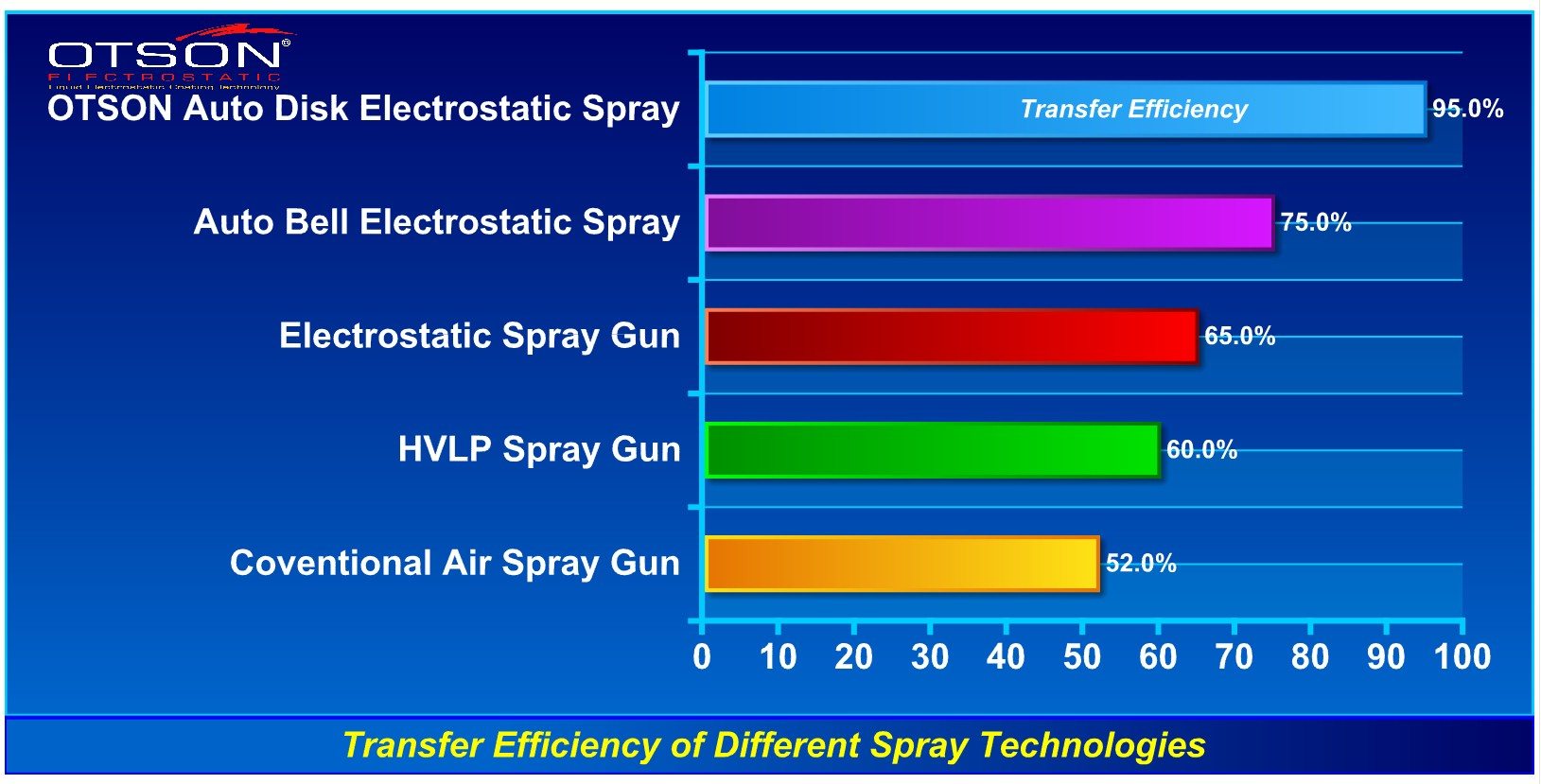

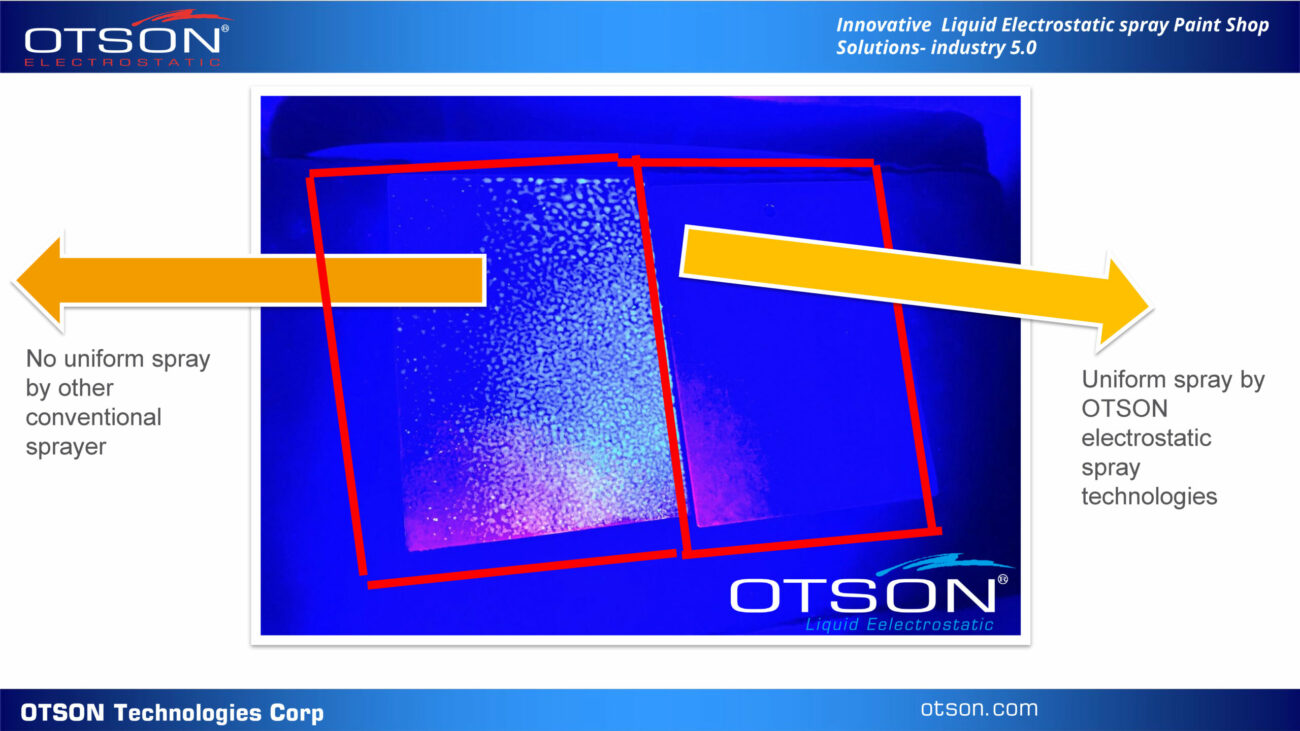

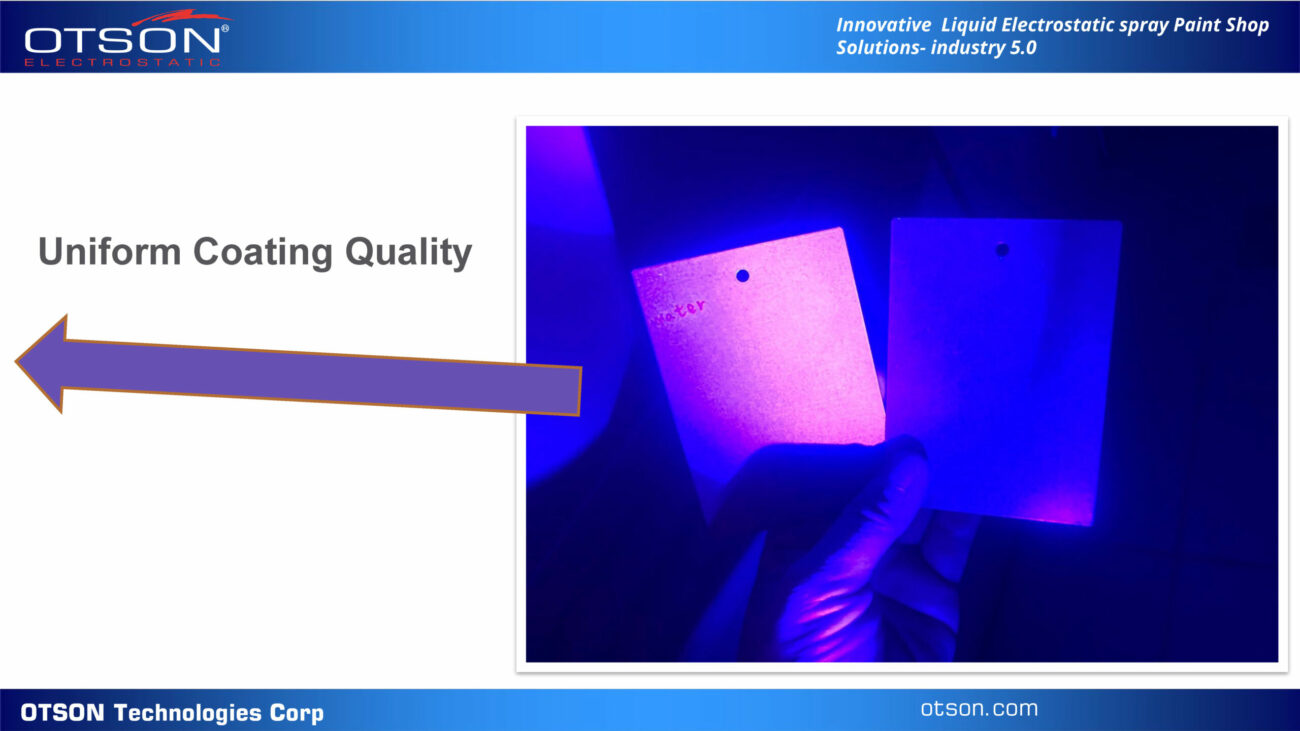

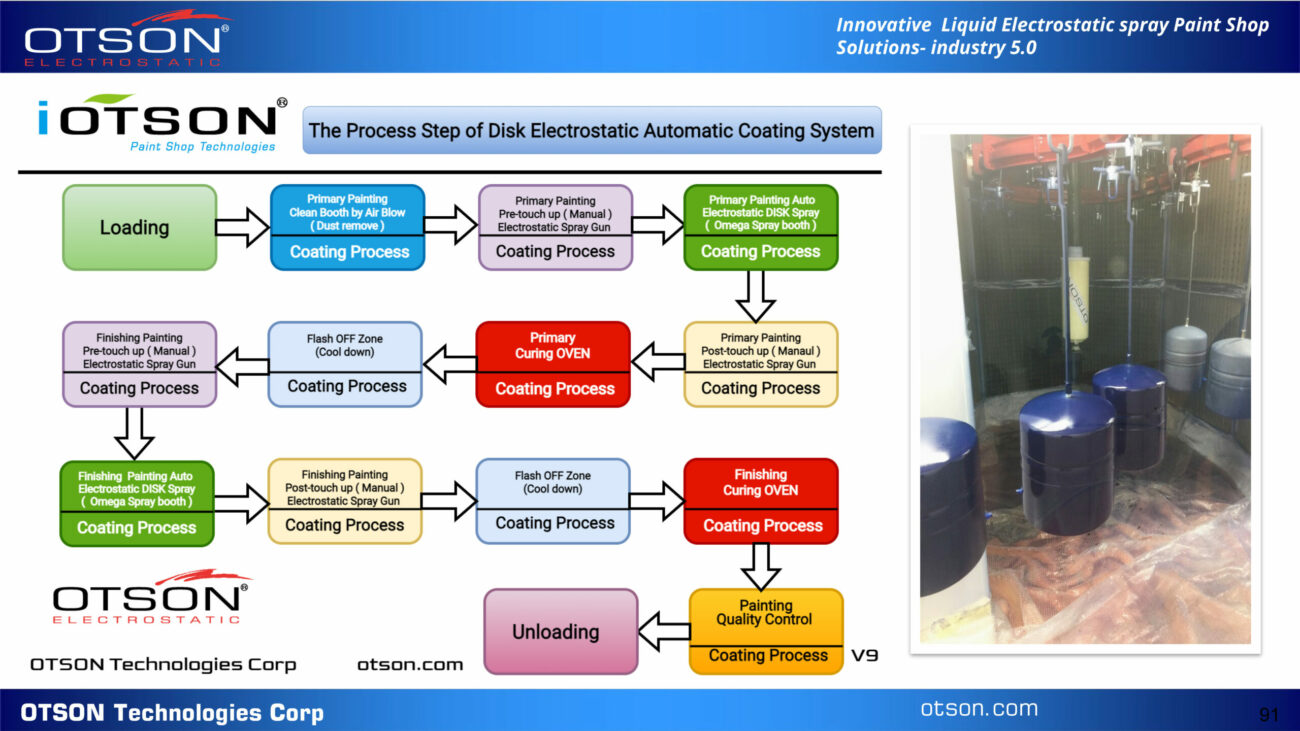

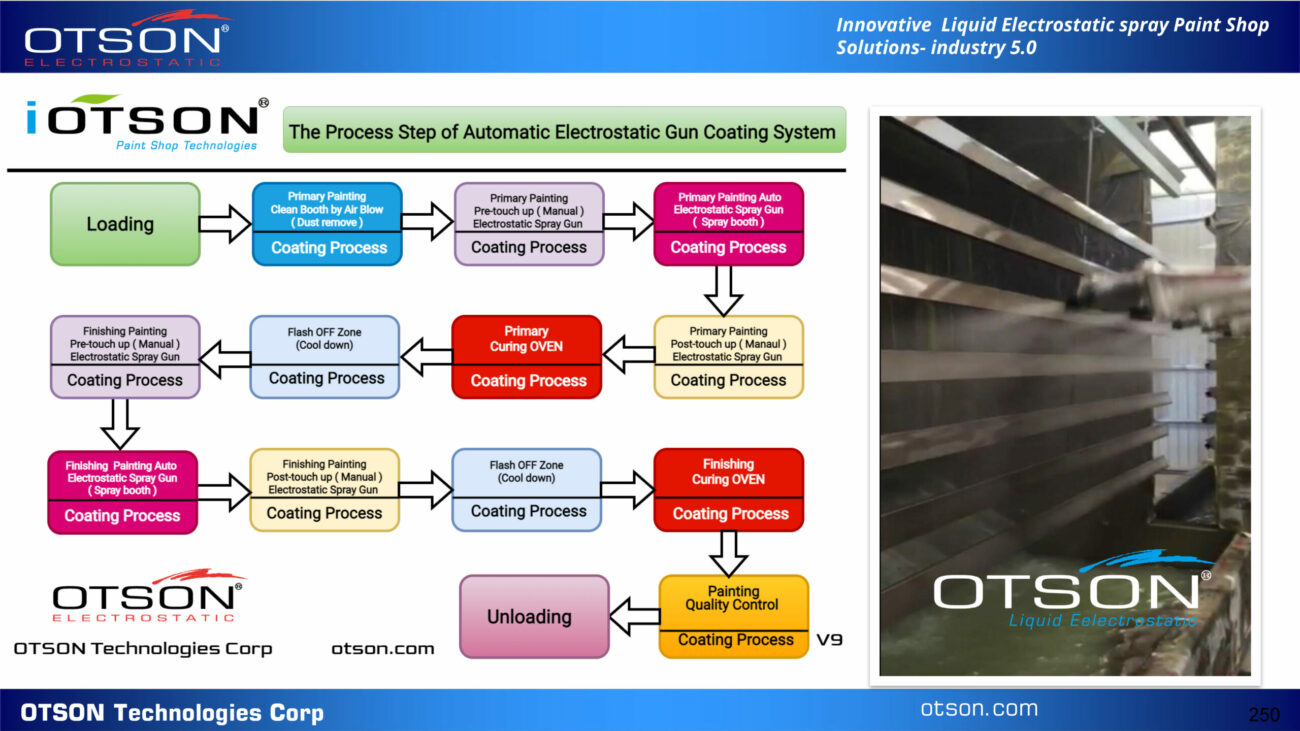

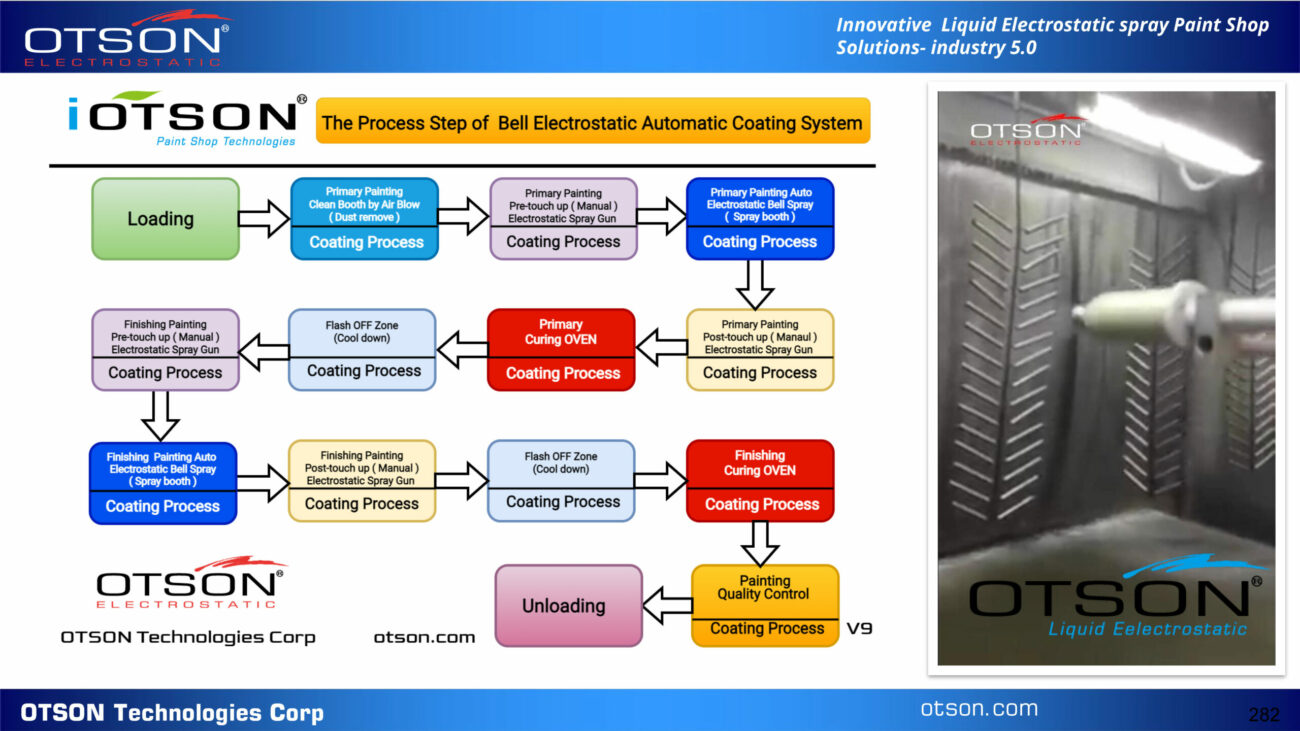

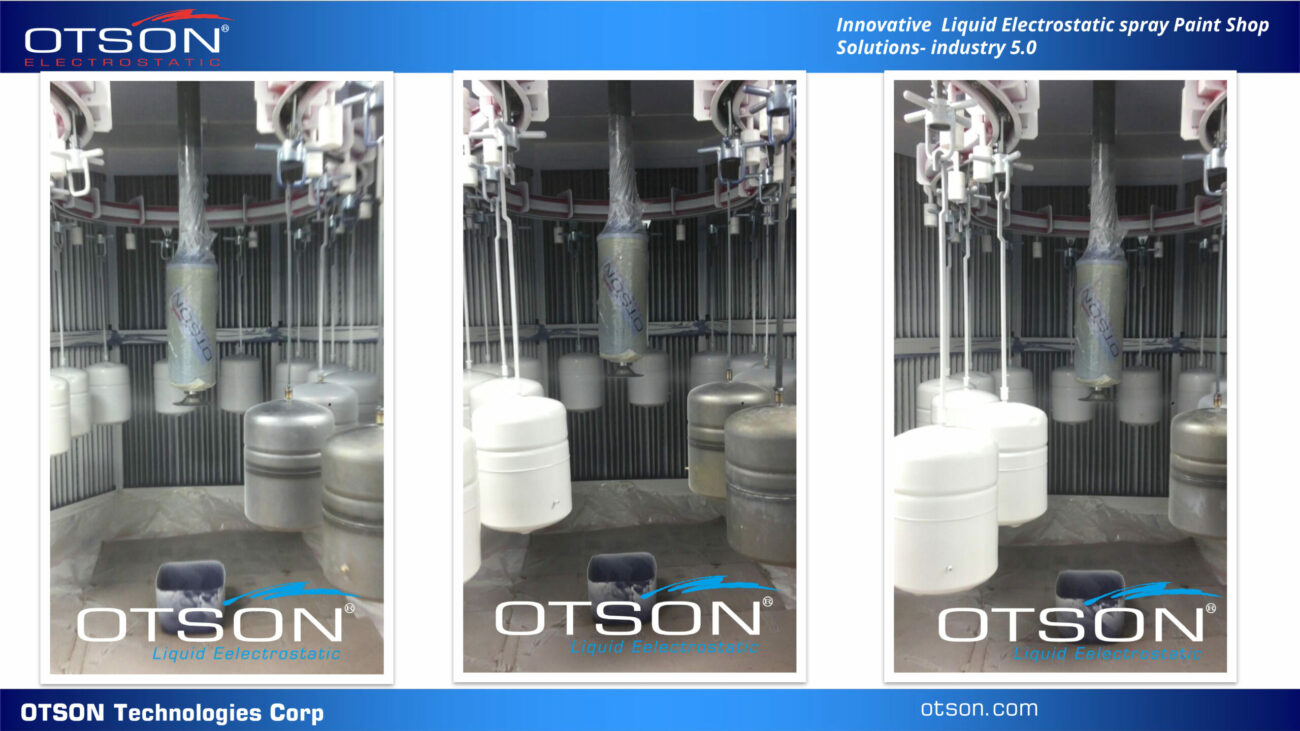

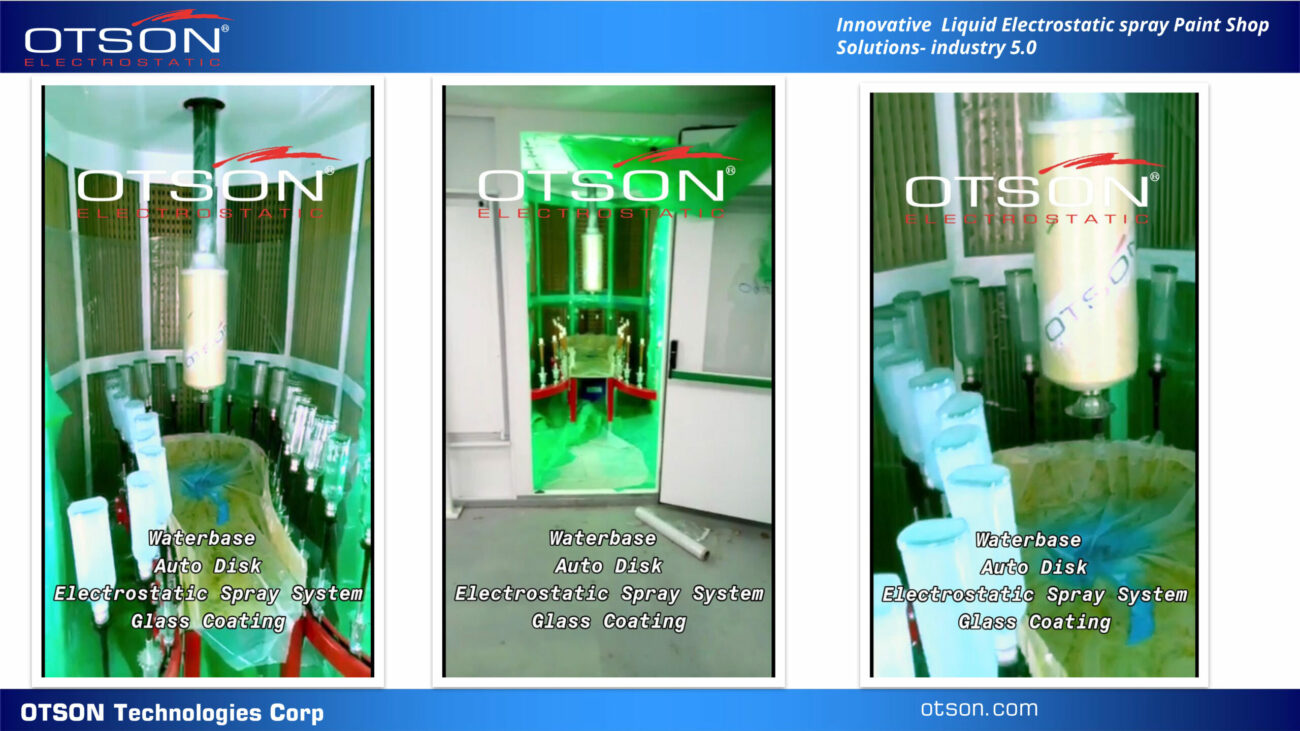

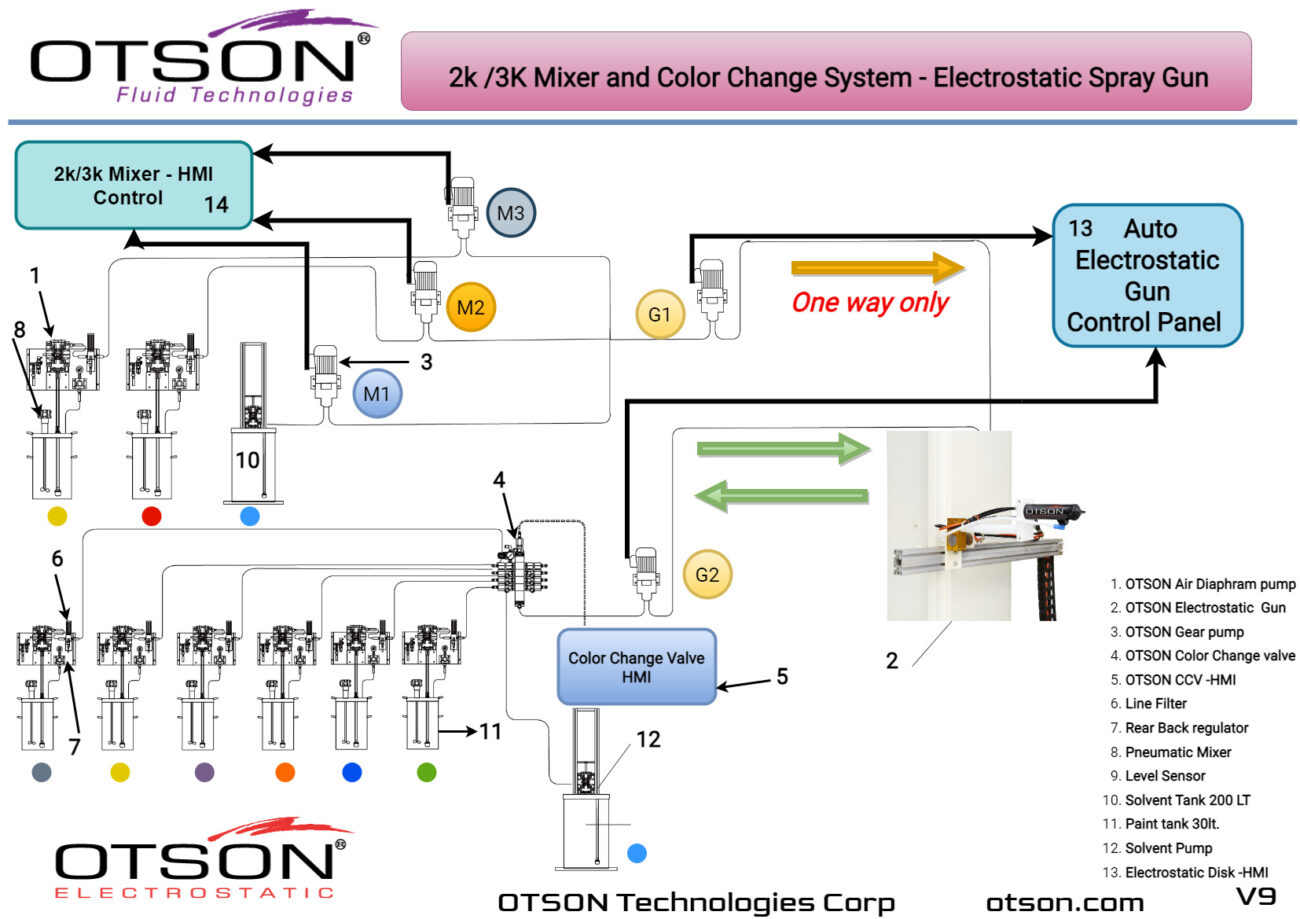

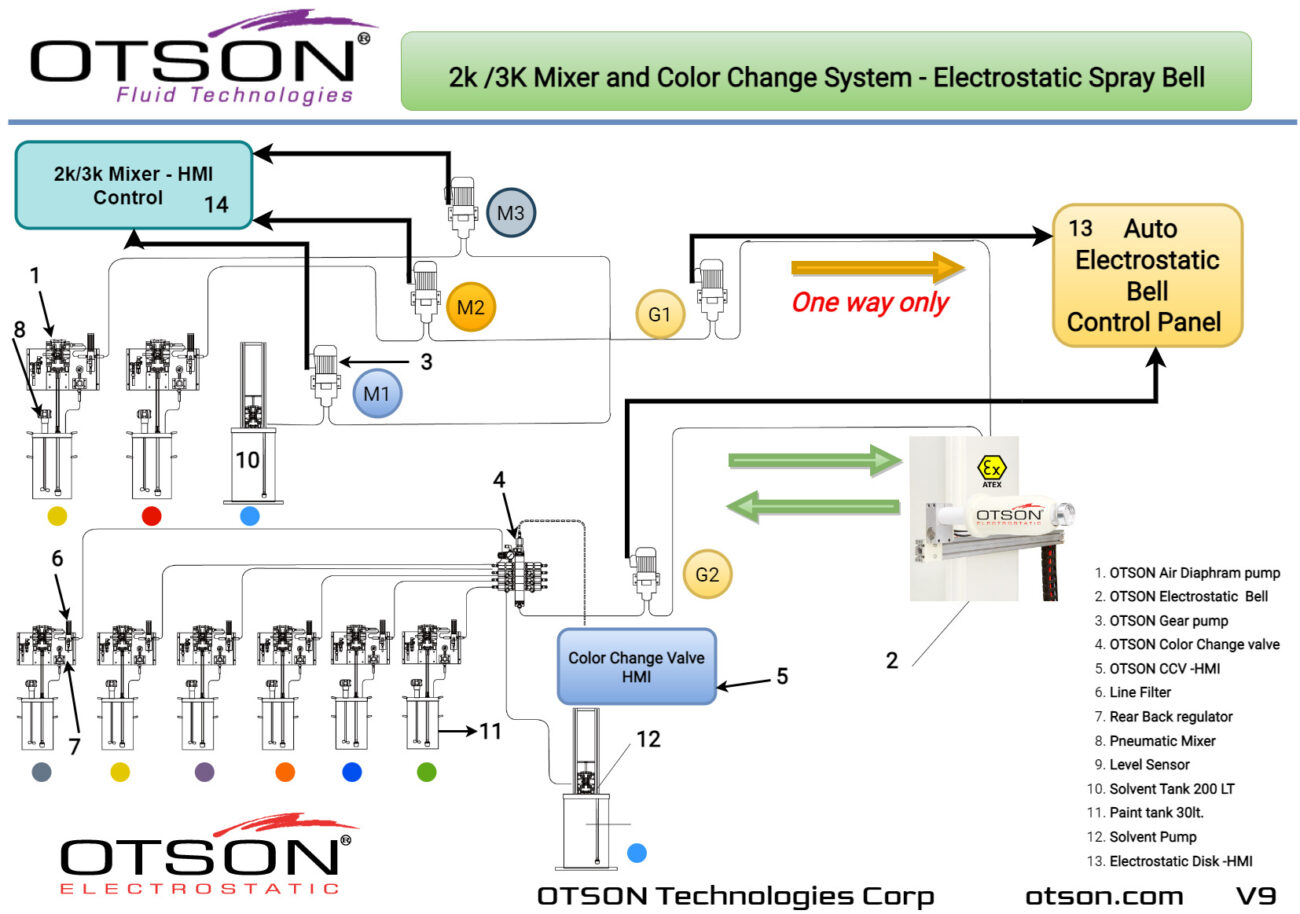

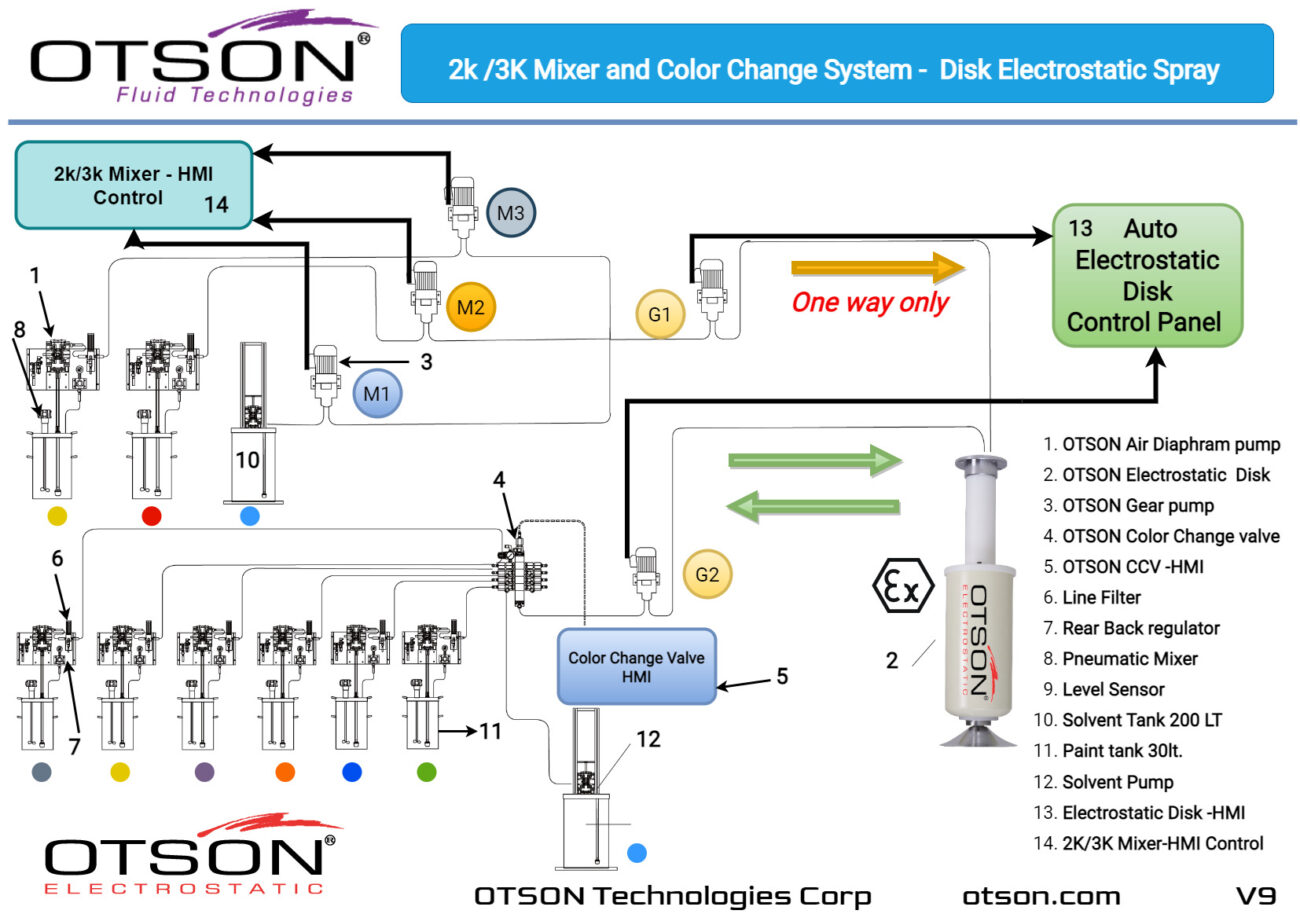

Our Auto DISK, Bell, and Gun electrostatic spray systems are also designed with the goal of efficiently utilizing energy, improving quality and protecting the environment which is in line with the current trend in the market. The market for electrostatic coating is relatively fragmented, with a number of large and small players vying for market share. However, OTSON’s systems stand out for their high transfer efficiencies, excellent edge coverage, and the ability to reduce paint waste and VOC emissions.

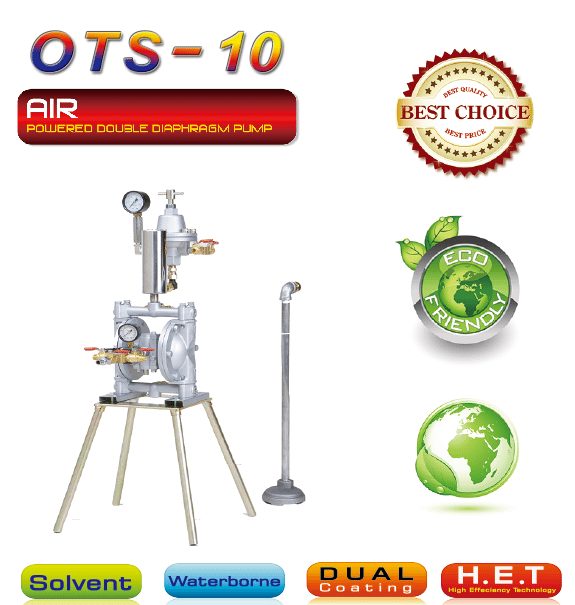

In addition to our electrostatic spray systems, we also offer fluid transfer technologies that are designed to transfer liquids and powders in industrial settings. Our fluid transfer systems are built to handle a wide range of liquids and powders, and are known for their durability, reliability, and safety.