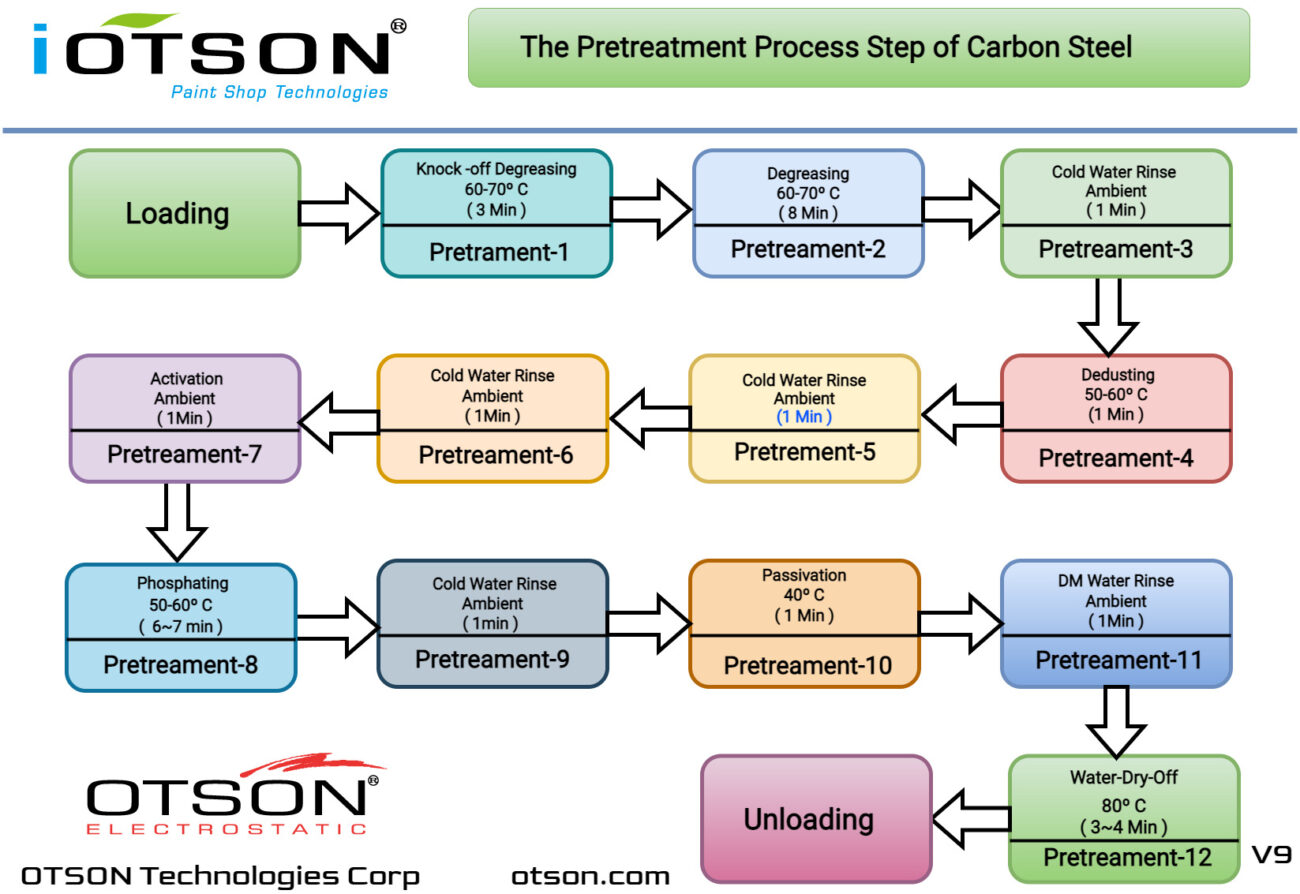

Before carbon steel can be coated using liquid or powder electrostatic spray, it is typically cleaned and pretreated to improve the adhesion of the coating. Some common pretreatment methods for carbon steel prior to electrostatic spray coating include:

- Degreasing: Degreasing is a process in which carbon steel is cleaned with a solvent or chemical solution to remove oils, greases, and other contaminants from the surface. This is typically the first step in the pretreatment process.

- Sandblasting: Sandblasting is a process in which abrasive particles are blasted against the surface of the carbon steel to remove contaminants and prepare the surface for coating. This process can also be used to create a rough surface texture to improve the adhesion of the coating.

- Phosphating: Phosphating is a process in which carbon steel is treated with a phosphoric acid solution to create a thin, protective layer on the surface. This layer helps to improve the corrosion resistance and paint adhesion of the steel.

- Acid etching: Acid etching is a process in which the surface of the carbon steel is treated with an acidic solution to create a roughened surface texture. This can be done using a variety of acidic solutions, such as hydrochloric acid or sulfuric acid. The surface of the carbon steel is typically immersed in the acid solution for a period of time, and then rinsed and neutralized to stop the etching process. Acid etching can improve the adhesion of the final coating by increasing the surface area and creating a rough, irregular surface.

- Abrasive blasting: Abrasive blasting is a process in which abrasive particles are blasted against the surface of the carbon steel to remove contaminants and prepare the surface for coating. This process is typically done using compressed air to propel the abrasive particles, which can be made of materials such as sand, glass beads, or aluminum oxide. Abrasive blasting can create a rough surface texture that can improve the adhesion of the final coating.

- Deburring: Deburring is a process in which burrs or other sharp edges are removed from the surface of the carbon steel. This can be done using mechanical means such as grinding or sanding, or with chemical deburring methods. Deburring is often done to improve the surface finish and prepare the steel for coating. It can also improve the appearance of the finished product and prevent injuries or damage during handling.

- Passivation: Passivation is a process in which the surface of the carbon steel is treated with a chemical solution to remove contaminants and create a passive layer on the surface. This layer is typically made up of a thin film of oxide or other compound that forms on the surface of the steel and helps to protect it from corrosion. Passivation can be done using a variety of chemical solutions, such as nitric acid or citric acid.

- Chromating: Chromating is a process in which the surface of the carbon steel is treated with a chromate solution to create a thin, protective layer on the surface. This layer is typically made up of a compound called chromium oxide, which forms on the surface of the steel and helps to improve its corrosion resistance and paint adhesion. Chromating can be done using a variety of chromate solutions, such as zinc chromate or aluminum chromate.

It is important to carefully clean and pretreat carbon steel prior to electrostatic spray coating to ensure that the coating adheres properly and provides the desired level of protection. The specific pretreatment methods used will depend on the intended use of the coated steel and the desired properties of the final coating.

Finally, it is also important to make sure that the electrostatic spray equipment is properly calibrated and maintained, and that the paint being used is compatible with the glass surface.

Additionally, by choosing OTSON’s electrostatic spray system, as a part of OTSONTechnologies, a professional paint shop manufacturer, you can benefit from the following advantages:

- Increased Efficiency: OTSON’s electrostatic spray systems are designed to increase the efficiency of the painting process, resulting in higher production rates and lower costs.

- Improved Quality: The precise application of paint provided by OTSON’s electrostatic spray systems can result in a higher-quality finish with fewer defects.

- Enhanced Safety: OTSON’s electrostatic spray systems are designed with safety in mind, minimizing overspray and minimizing the need for manual touch-ups.

- Customizable Solution: OTSONTechnologies can provide a customized solution tailored to your specific needs and requirements.

- Trusted Brand: OTSONTechnologies is a well-established brand in the industry, known for its high-quality products and excellent customer service.

OTSON Technologies Corp. is a well-known provider of cutting-edge paint shop solutions for various industrial and commercial markets. Our extensive range of products and services are designed to help our clients improve their painting processes, reduce costs, and increase overall efficiency. With years of experience as a reputable manufacturer, we take pride in delivering high-quality products and services to meet the needs of our valued customers.

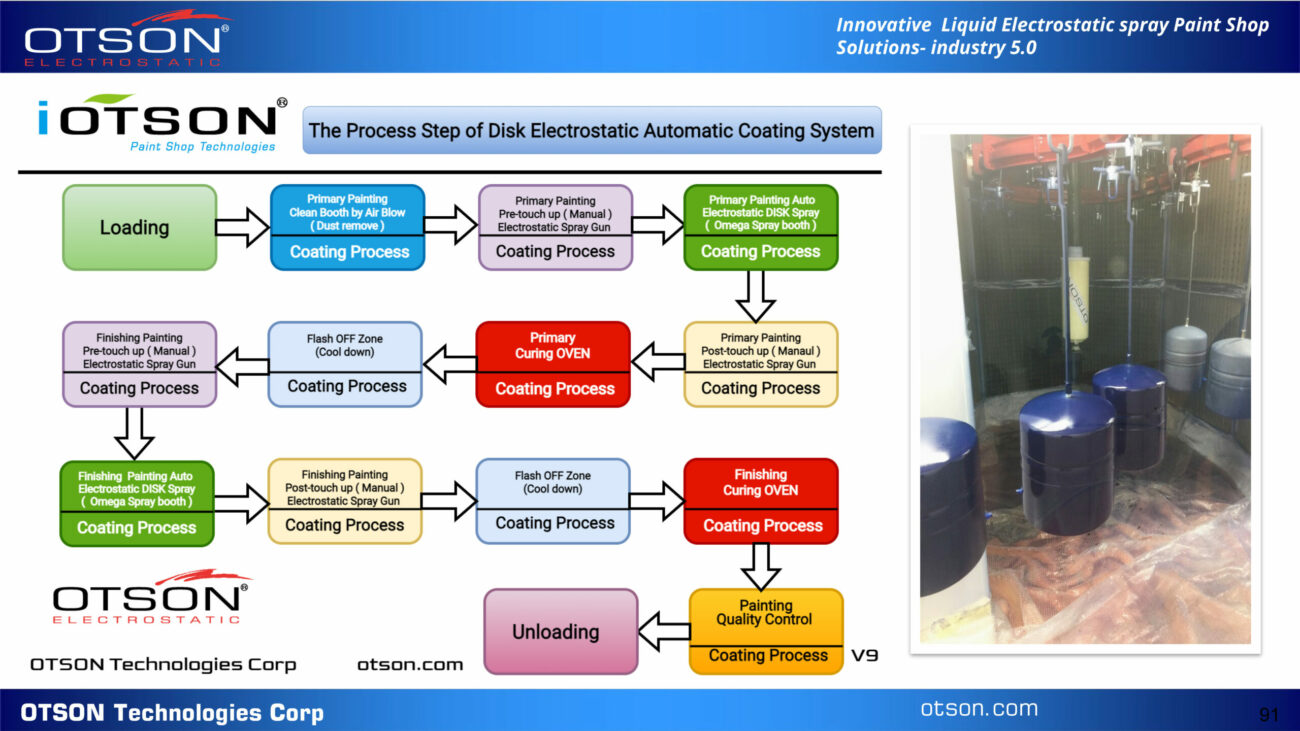

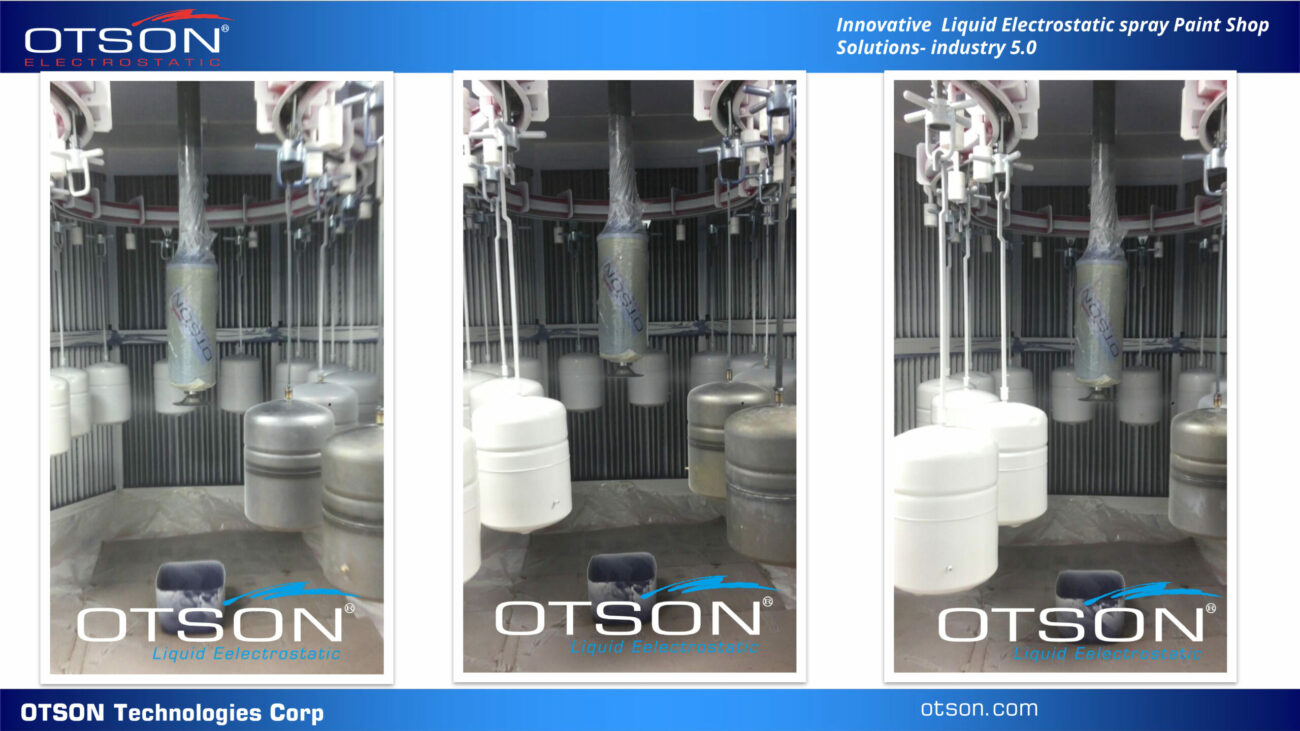

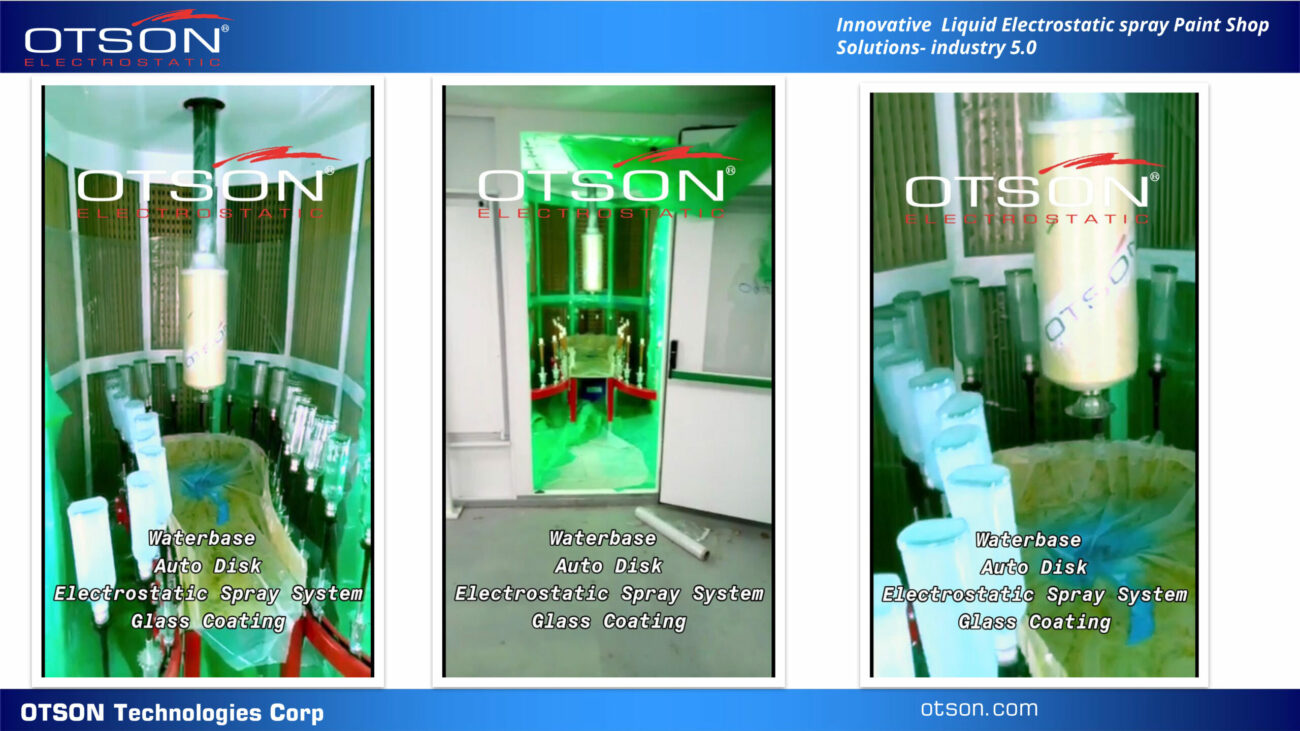

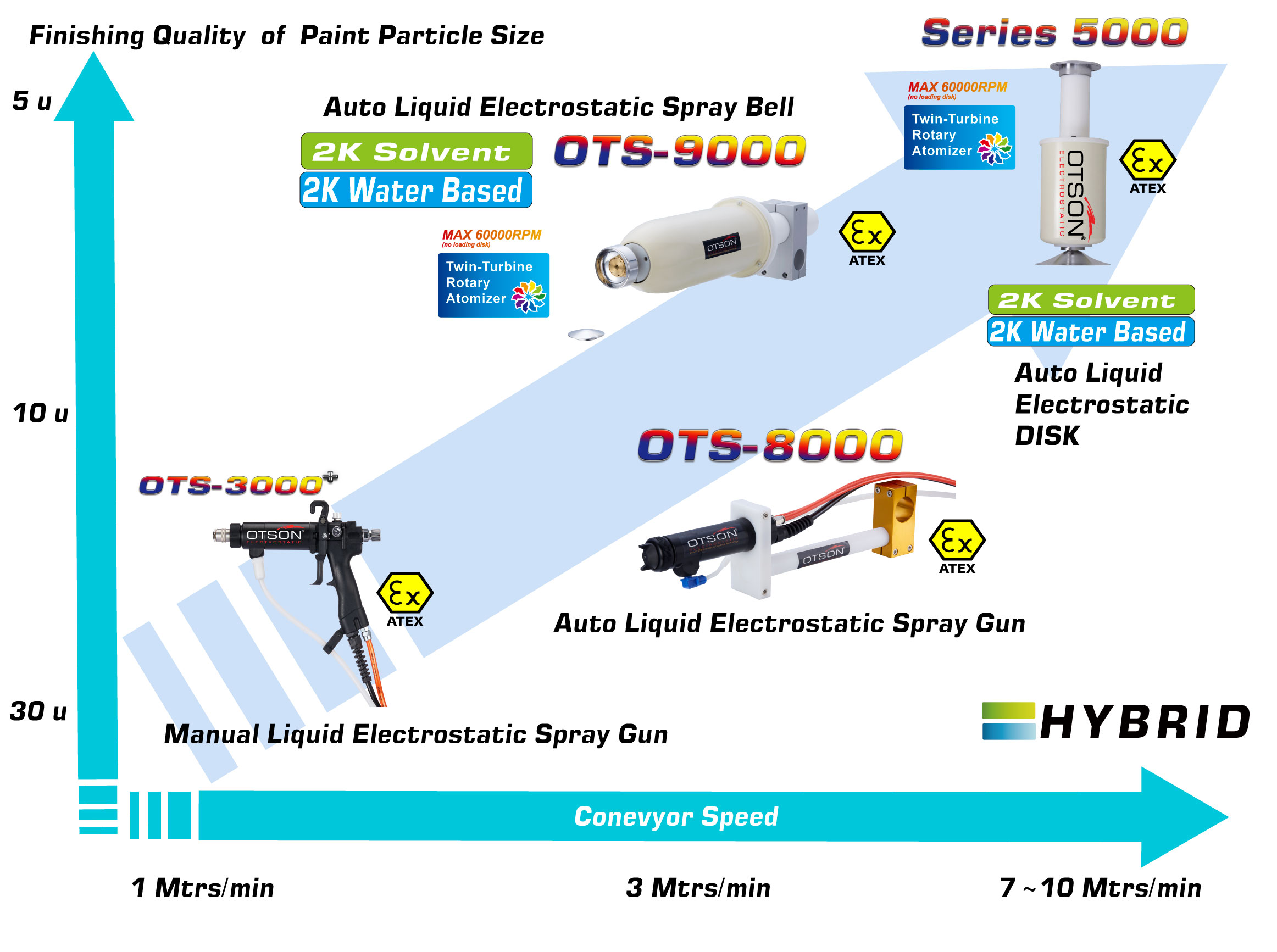

One of our flagship products is the OTSON Liquid Electrostatic, which features innovative technology and patented designs for electrostatic liquid coating and fluid transfer applications. Our product range includes a wide variety of equipment options such as disc and bell systems that cater to the unique requirements of various industries and applications.

OTSON Liquid Electrostatic systems are renowned for their precision, high efficiency, and reliability. Our products are specifically designed to minimize paint waste and increase production rates, resulting in a significant return on investment for our customers. Furthermore, our systems meet industry safety standards with ATEX certification, ensuring the delivery of high-quality finishes to our clients.

At OTSON, we understand the significance of offering complete solutions to cater to the diverse needs of our clients. Therefore, we are committed to integrating our OTSON Liquid Electrostatic systems with our smart paint shop solutions that provide greater process control, enhanced efficiency, and improved quality.

If you are looking for a reliable and efficient liquid electrostatic coating system, OTSON’s OTSON Liquid Electrostatic line is the perfect choice. Get in touch with us today to learn more about our products and services, and how they can benefit your business.

There are several advantages to using electrostatic spray coating over traditional spraying methods:

Electrostatic spray coating is a popular choice for mass production factories due to the many benefits it offers over traditional coating methods. Some of the key advantages of using electrostatic spray coating include:

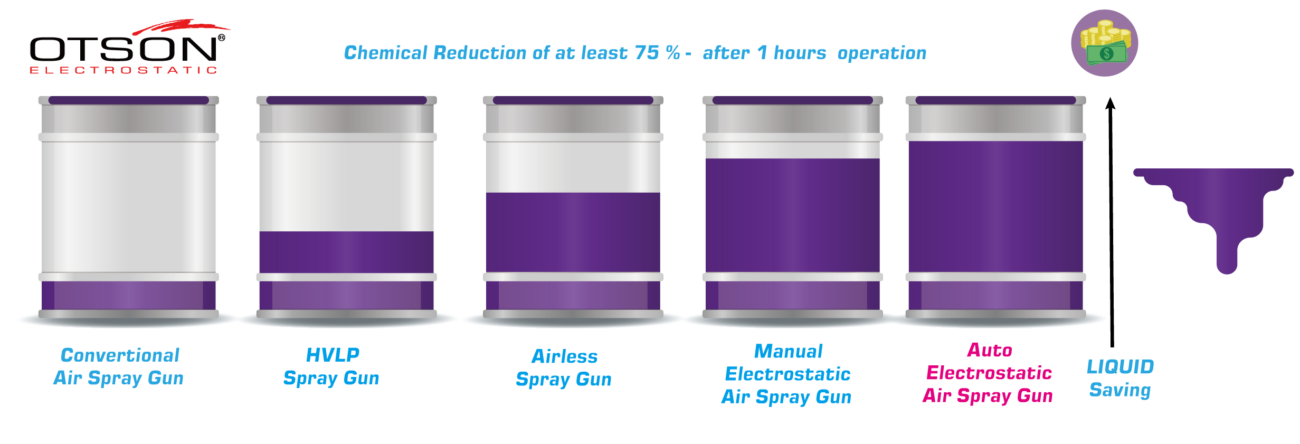

- High Spray Efficiency: Electrostatic spray coating is highly efficient, requiring less material to achieve the desired coating thickness. This leads to cost savings and reduced waste.

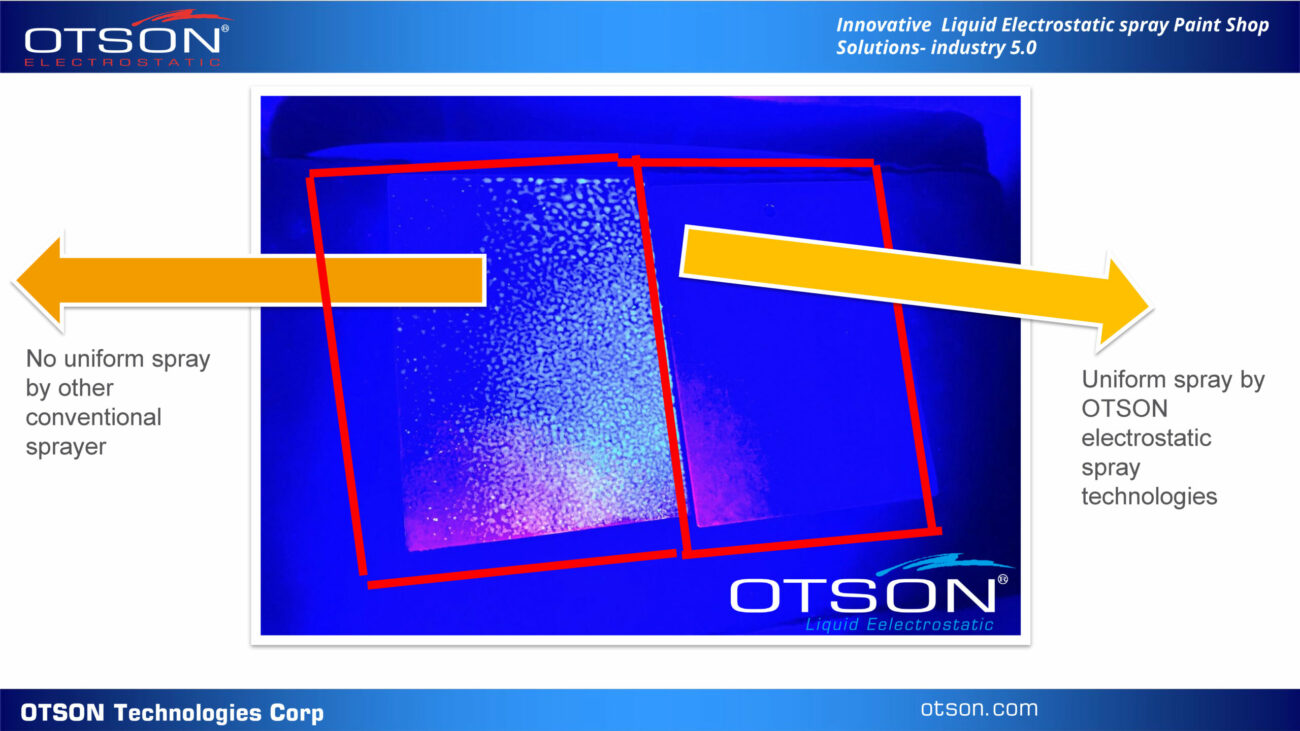

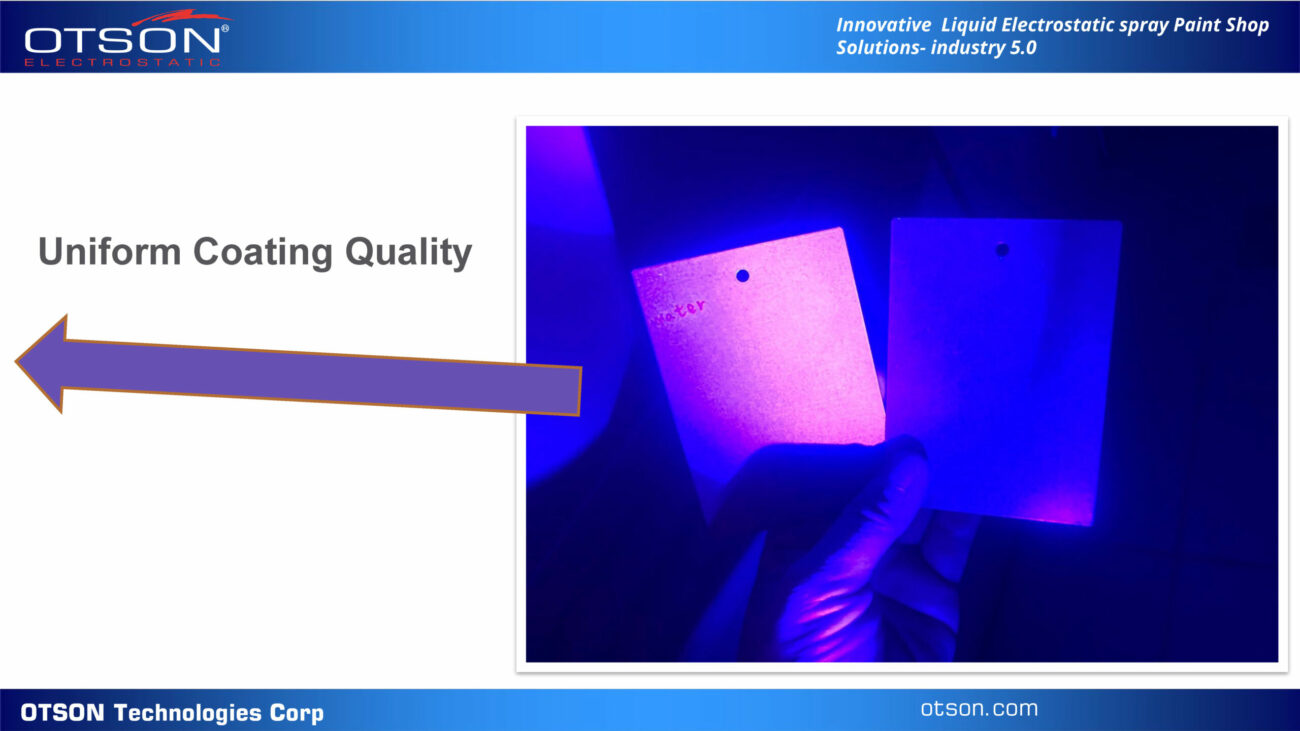

- Uniform Coating: Electrostatic spray coating creates a uniform coating on the surface of the product, thanks to the electrostatic charge that attracts the coating material to the surface. This ensures even distribution, resulting in a higher quality finished product with fewer defects.

- Lower Environmental Impact: Electrostatic spray coating has a lower impact on the environment than some traditional coating methods. It produces less air and water pollution and can be used in enclosed areas with proper ventilation, reducing the amount of overspray and waste.

- Advancements in Electrostatic Coating Equipment: In recent years, there have been significant advancements in electrostatic coating equipment. High-voltage electrostatic generators, new structures for electrostatic spray guns, and new automatic control panels have enhanced the reliability and efficiency of the electrostatic coating process, providing a solid foundation for its continued development and implementation in various industries.

Overall, electrostatic spray coating is a versatile, efficient, and sustainable method that is widely used in various industries, including automobiles, bicycles, wheels, instrumentation, electrical appliances, agricultural machinery, household electrical appliances, daily hardware, steel furniture, doors, windows, power tools, toys, gas appliances, and other industrial fields. The benefits of electrostatic spray coating make it an ideal choice for businesses looking to improve their coating processes, reduce costs, and increase efficiency while reducing their environmental impact.

Electrostatic spraying is a highly efficient and cost-effective coating method that has become increasingly popular across a range of industries. Here are some key features and benefits of using electrostatic spray equipment in your paint shop:

- Increased efficiency: Electrostatic spraying allows for a more efficient use of paint, resulting in significant cost savings and reduced waste.

- Improved coating quality: Electrostatic spray equipment provides a more even and consistent coating, resulting in a higher-quality finish, improved product durability, and longer lifespan for the coated item.

- Greater flexibility: Electrostatic spray equipment can be used for a wide range of coating applications, including large and irregularly shaped objects, making it a versatile solution for many different industries.

- Increased safety: Electrostatic spraying reduces the amount of overspray and allows for a safer working environment by eliminating the need for excessive amounts of paint in the air.

- Reduced downtime: Electrostatic spray equipment is easy to clean and maintain, reducing downtime and increasing productivity.

- ROI-friendly: Electrostatic spray equipment has a relatively low initial investment cost and is known to have a relatively short payback period, making it a cost-effective solution for many businesses.

- Energy-efficient: Electrostatic spray equipment typically uses less energy than traditional spray equipment, leading to cost savings and a reduced environmental impact.

- Environmental-friendly: Electrostatic spray equipment results in reduced emissions, leading to a smaller environmental footprint.

Overall, electrostatic spray equipment can provide a wide range of benefits for paint shops, from increased efficiency and improved coating quality to greater flexibility and increased safety. With its relatively low initial investment cost and short payback period, it can be a cost-effective and environmentally-friendly solution that can improve the ROI of your paint shop operations.

Water-based electrostatic spray coating has a variety of features that make it a popular and environmentally friendly coating option. Here are some of the key features of this process:

- Environmentally friendly: Water-based electrostatic spray coating produces fewer emissions and less VOCs than solvent-based coatings, making it a more environmentally friendly option.

- High-quality finish: The electrostatic charge created during the spraying process ensures that the coating material is uniformly attracted to the substrate, resulting in a high-quality finish.

- Wide range of substrates: Water-based electrostatic spray coating can be used on a wide range of substrates, including metals, plastics, and composites.

- Versatility: This process can be used to coat a variety of products, such as automobiles, bicycles, electrical appliances, agricultural machinery, household items, steel furniture, and more.

- Specialized equipment: Water-based electrostatic spray coating requires specialized equipment, including a high-voltage electrostatic generator, a water-based electrostatic spray gun, and a control panel that regulates the voltage and flow rate of the coating material.

- Proprietary technology: Some companies, such as OTSON, have developed proprietary technology that ensures optimal performance of the equipment and the coating.

Overall, water-based electrostatic spray coating is an environmentally friendly and high-quality coating process that can be used on a wide range of substrates and products. Its specialized equipment and proprietary technology make it a versatile solution for many different industries.

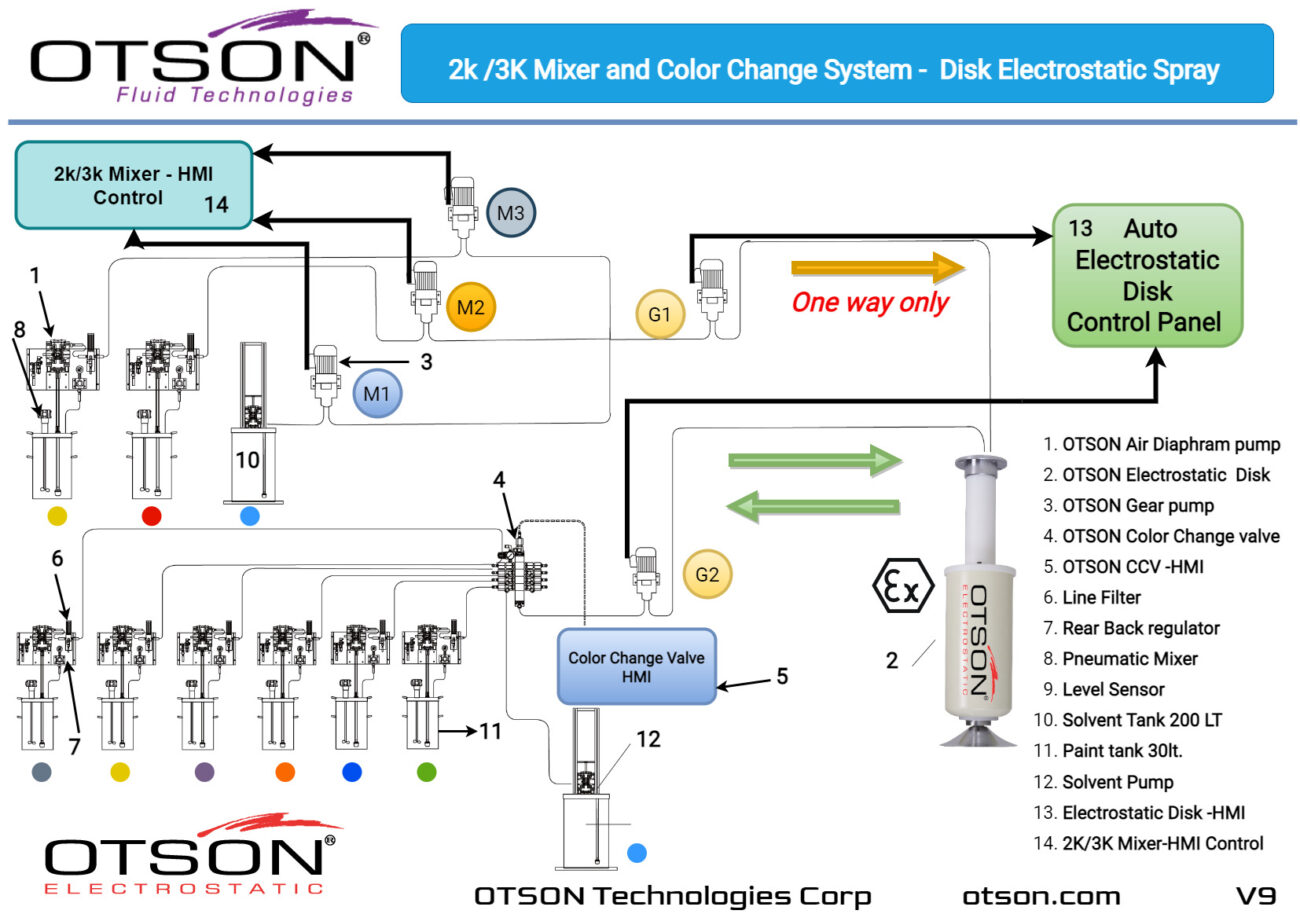

Spray System | Productive rate | Spray Pattern | Paints Consumption | Atomizing Performance | Spray Booth Style |

Excellent: Coating works is done simultaneously for all objects around Disk atomizer | Good for mass production Disk Reciprocator stroke distance could be customized according to hanger size ( Conveyor speed is workable for 7Mtrs/min ) | Low: High atomizing performance is achieved by OTSON precision structure. | Excellent ( 60,000 RPM) | OMEGA Spray Booth | |

Good: Bell Cup atomizer stroke from down to up Note: by Bell system, it is not suitable for rotating hangers | High atomizing Bell Cup, spray pattern is around 25cm ( Diameter ). Conveyor speed: between 1.8 Mtrs/min - 2.0 Mtrs/min suggestion | Low: High atomizing performance is achieved by OTSON precision structure. | Excellent (60,000 RPM) | Side by Side Spray Booth | |

Good: Flexible for various objects such as platform-like objects and multiple shape object | 4 types of spray pattern nozzles for options Conveyor speed: 4 Mtrs/min suggestion | Acceptable: ( Auto spray gun is driven by air, its paintings consumption will be more than Bell and disk coating system ) | Side by Side Spray Booth |

- Electrostatic atomizer spray systems use an electrostatic charge to apply a coating material to a surface. The charge is generated by an electrical current applied to the coating material as it is atomized into fine droplets.

- The charged droplets are attracted to the surface being coated, allowing for more precise application and a more even finish. The charge also helps to increase the transfer efficiency of the coating material, resulting in less material being used and potentially reducing costs.

- Electrostatic atomizer spray systems are often used in the automotive, aerospace, and manufacturing industries to apply paints, coatings, and other finish materials. They can be used to coat a wide range of surfaces, including metal, plastic, and composite materials.

- Electrostatic atomizer spray systems have several advantages over traditional spraying methods, including improved precision, reduced overspray, increased efficiency, and better transfer efficiency. They also offer greater control over the coating process and can be more environmentally friendly, as they often produce fewer volatile organic compounds (VOCs) compared to other coating methods.

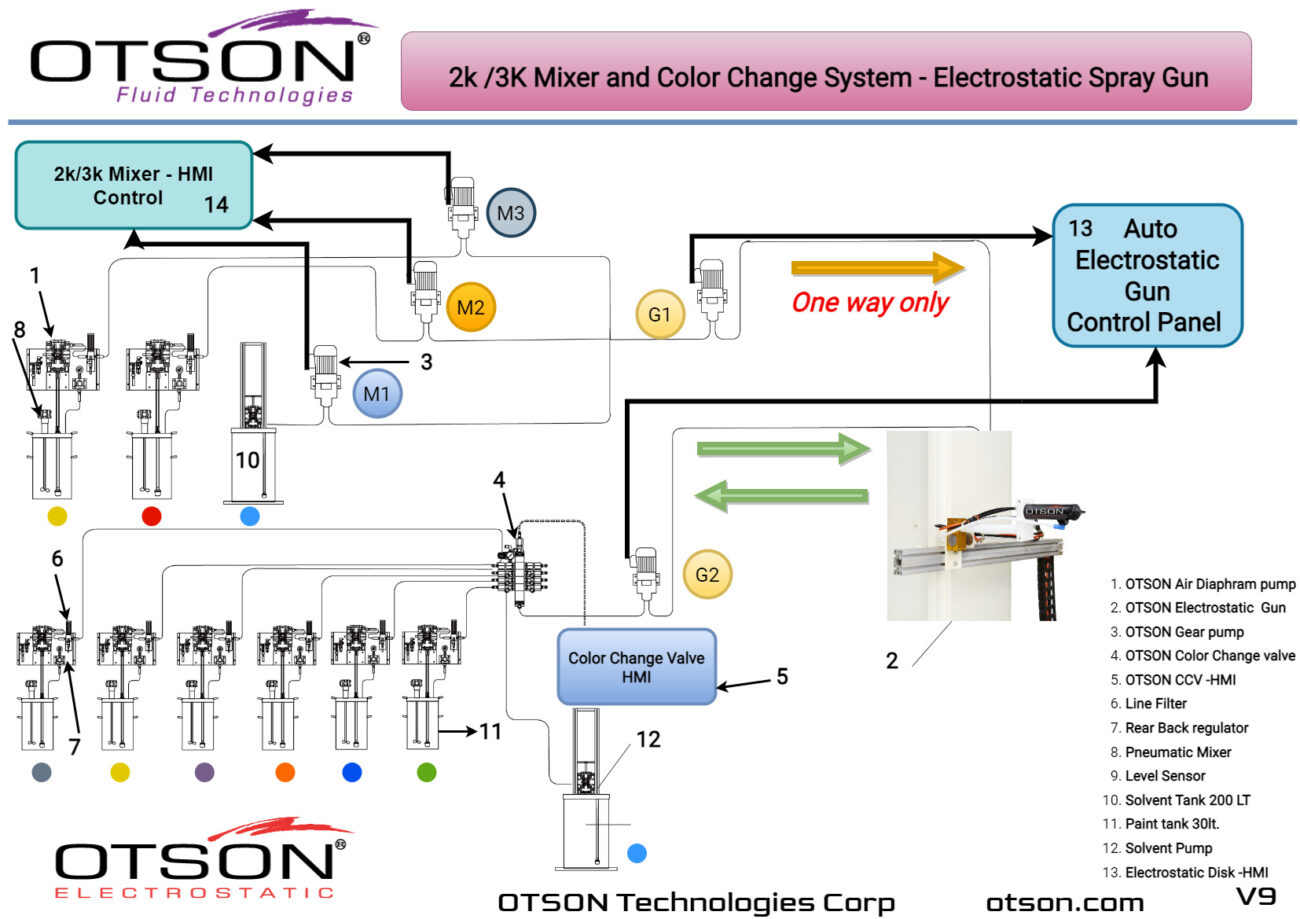

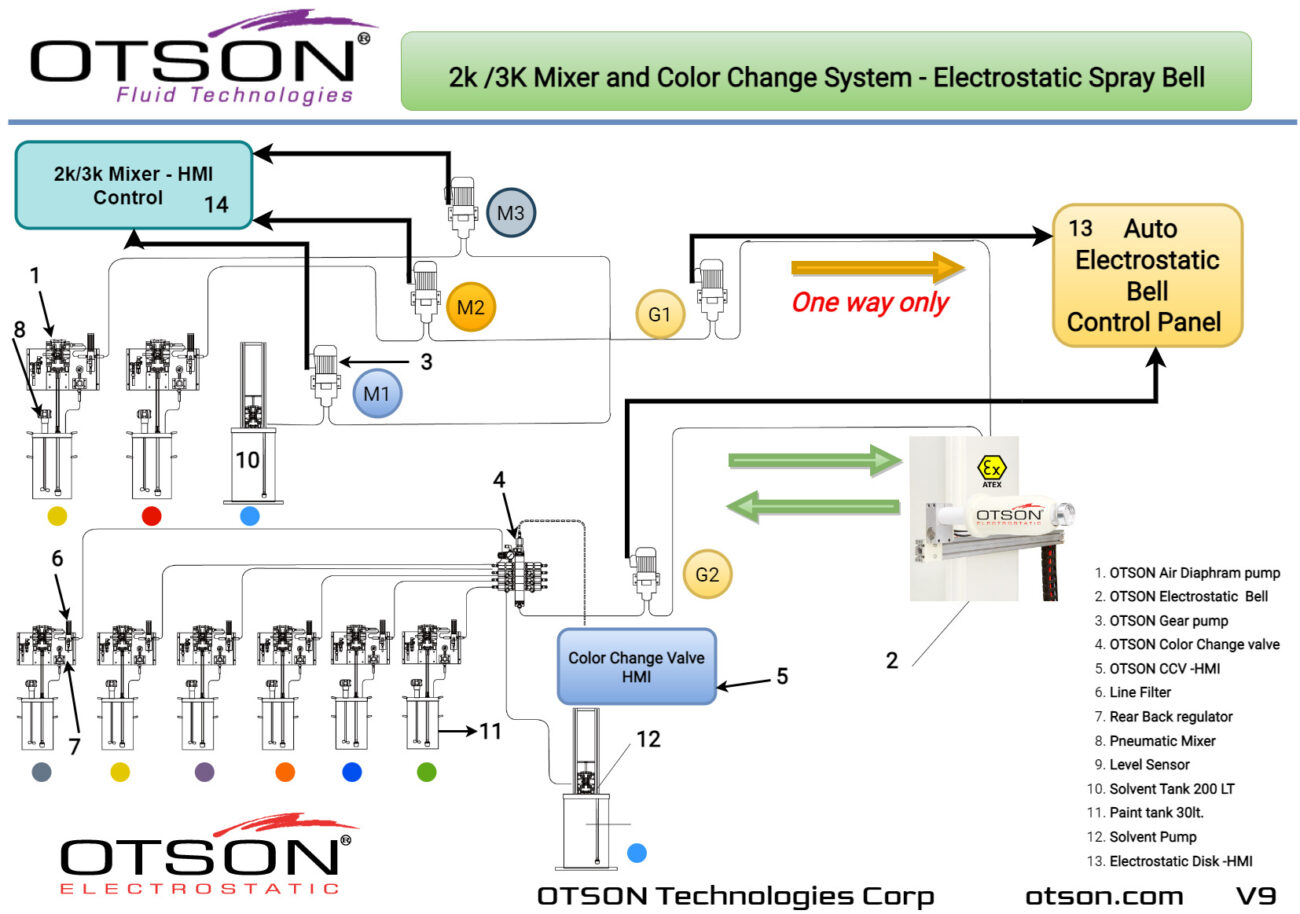

The Auto Color Change System is a technical solution for liquid electrostatic spray equipment, such as auto electrostatic spray bell, auto electrostatic spray disc, and auto electrostatic spray gun. This system is designed to provide rapid and accurate color changes for spray equipment in industrial applications, including automotive, aerospace, and other manufacturing processes.

The Auto Color Change System utilizes a series of valves and pumps to control the flow of paint and the color change process. The system is fully automated, reducing the need for manual intervention and streamlining the painting process. This makes it possible to change colors quickly and accurately, resulting in improved productivity and reduced waste.

Here are some of the key features of the Auto Color Change System:

- Fast and Accurate Color Changes: The system is designed for rapid and accurate color changes, allowing for improved productivity and reduced downtime.

- Fully Automated: The Auto Color Change System is fully automated, minimizing the need for manual intervention and streamlining the painting process.

- Versatile: The system is compatible with a wide range of paint types, including solvent-based and water-based paints, making it adaptable to various industrial applications.

- Programmable: The user-friendly interface and controls make it easy to program and operate, allowing for quick and seamless color changes.

- High-Quality Finishes: The Auto Color Change System enables the application of a consistent and high-quality finish, improving the overall quality of the paint job.

- Customizable: The system can be customized to handle a range of color changes, from two to twenty or more, depending on the specific needs of the application.

- Efficient: The system reduces waste and cleanup time, making it an efficient solution for industrial painting processes.

- Reliable: The Auto Color Change System is designed to be reliable and long-lasting, ensuring consistent performance over time.

In conclusion, the Auto Color Change System for liquid electrostatic spray equipment provides a technical solution for efficient and accurate color changes. It is an essential component of industrial painting processes, providing high-quality finishes and improving productivity while reducing waste. The system is versatile, compatible with a range of paint types, and can be customized to meet the specific needs of any industrial application. With its fully automated and programmable features, the Auto Color Change System offers a reliable and efficient solution for liquid electrostatic spray equipment.

Color change valves, also referred to as paint dispensers, are a must-have for any painting industry business. These devices are specifically designed for paint shops to accurately and quickly dispense paint, resulting in a reduction of waste and cleanup time.

One of the most notable benefits of color change valves is their ability to automatically switch between various paint colors. This feature saves time and increases efficiency, which is especially helpful for businesses that work on multiple projects and require frequent color changes.

Color change valves are also highly capable of mixing paint with hardeners, reducers, and other additives while it is being dispensed. This feature ensures that the paint is accurately mixed, improving the overall quality of the paint job.

In terms of market view, color change valves are commonly used in industrial paint applications such as automotive, aerospace, and wood finishing industries. Companies invest in color change valves to enhance their production efficiency and reduce costs.

In conclusion, color change valves are an integral part of any paint shop, providing accurate and efficient paint dispensing and color change capabilities. Investing in a top-quality color change valve can significantly increase productivity, enhance the quality of paint jobs, and ultimately save businesses money in the long run.

-

Automotive: cars, trucks, buses, motorcycles, and other vehicles.

-

Aerospace: airplanes, helicopters, satellites, and other aircraft.

-

Manufacturing: industrial equipment such as machinery, conveyor systems, tanks, and other metal structures.

-

Marine: ships, boats, yachts, and other watercraft.

-

Furniture: chairs, tables, cabinets, and other furniture pieces.

-

Medical: medical equipment such as MRI machines, X-ray machines, and surgical instruments.

-

Appliance: household appliances such as refrigerators, ovens, dishwashers, and other large appliances.

-

Agricultural: farm equipment and machineries, such as tractors, plows, and harvesters.

-

Construction: buildings, bridges, and other structures such as towers and cranes.

-

Electrical: electrical equipment and devices such as transformers, switchgear, and other high voltage equipment.

-

Sporting Goods: bicycles, exercise equipment, and other sports-related items.

-

Signage: signs, billboards, and other forms of advertising.

-

Retail: store fixtures, displays, and other items found in retail settings.

-

Food & Beverage: food processing and packaging equipment, beverage dispensing equipment, and other items found in food and beverage manufacturing facilities.

-

Small parts: gears, bolts, and other small metal components.

-

Bicycle: frames, forks, and other components of bikes.

-

Computer housing: exterior of computer towers, monitors, and other electronic devices.

-

Stationeries: pens, pencils, and other writing instruments.

-

Wooden furniture: wooden chairs, tables, and other pieces of furniture.

-

Hardware: locks, knobs, and other hardware items.

-

Lockers: exterior of metal lockers.

-

Freezers: exterior of commercial freezers and refrigeration units.

-

Iron railing: exterior of iron railings, fences, and other metal structures.

-

Major Appliances: washing machines, dryers, and other large household appliances.

-

Office equipment: printers, copiers, and other office machines.

-

Desks: exterior of desks and other office furniture.

-

Files: exterior of metal file cabinets and storage units.

-

Office partitions: exterior of office partitions and dividers.

-

Medical Equipment: surgical instruments, x-ray machines, and other medical devices.

-

Metal doors: exterior of metal doors, including commercial and industrial doors.

-

Car accessories: mirrors, spoilers, and other aftermarket car parts.

-

Teflon pots: exterior of Teflon-coated pots and pans.

-

Musical instruments: guitars, pianos, and other musical instruments.

-

Environmental equipment: air purifiers, water filtration systems, Water Tanks, and other environmental equipment.

-

Plastic products: plastic toys, bottles, and other plastic products.

-

Metal products: metal signs, metal sculptures, and other metal products.

-

Glass products: glass bottles, windows, and other glass products.

-

Military:

-

Wind Power :