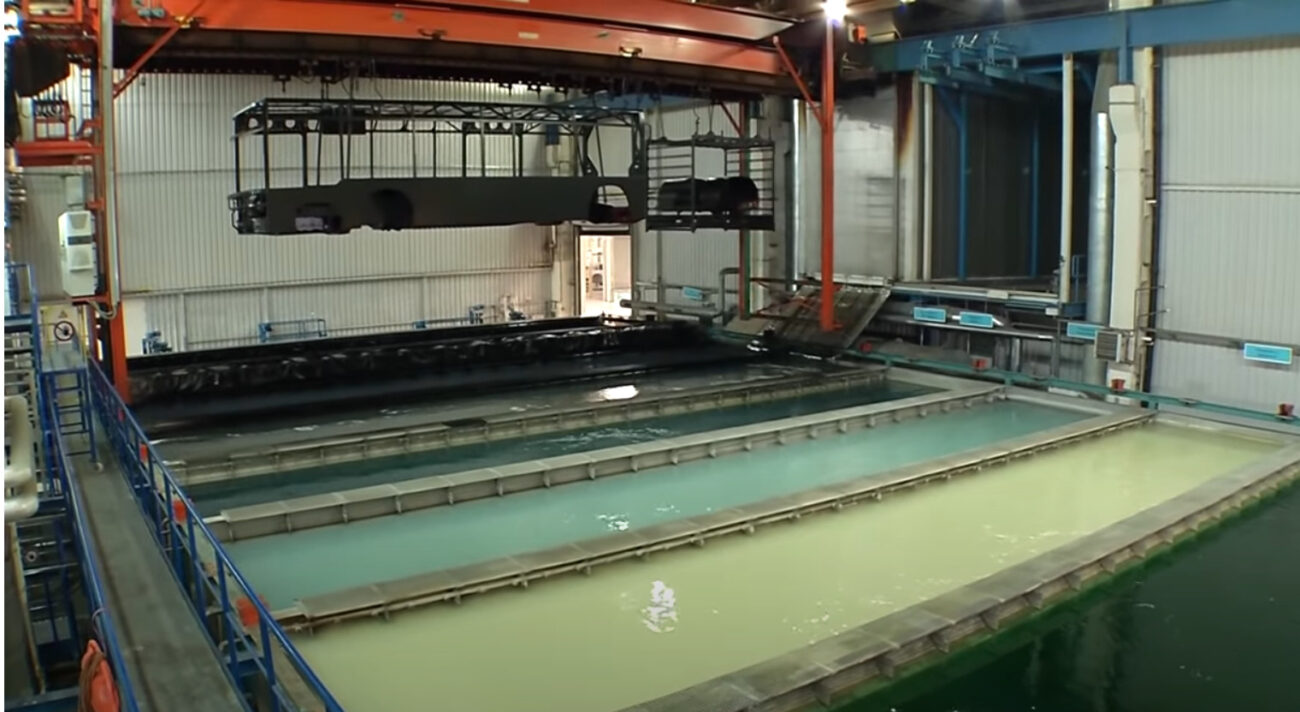

Pretreatment Process – Paint Shop

At OTSON Technologies Corp, we understand the importance of proper surface preparation ( Pretreatment Process) before electrostatic spray coating. That’s why we offer a comprehensive service that includes both surface preparation and electrostatic spray coating, ensuring that your projects are completed to the highest standards of quality and safety.

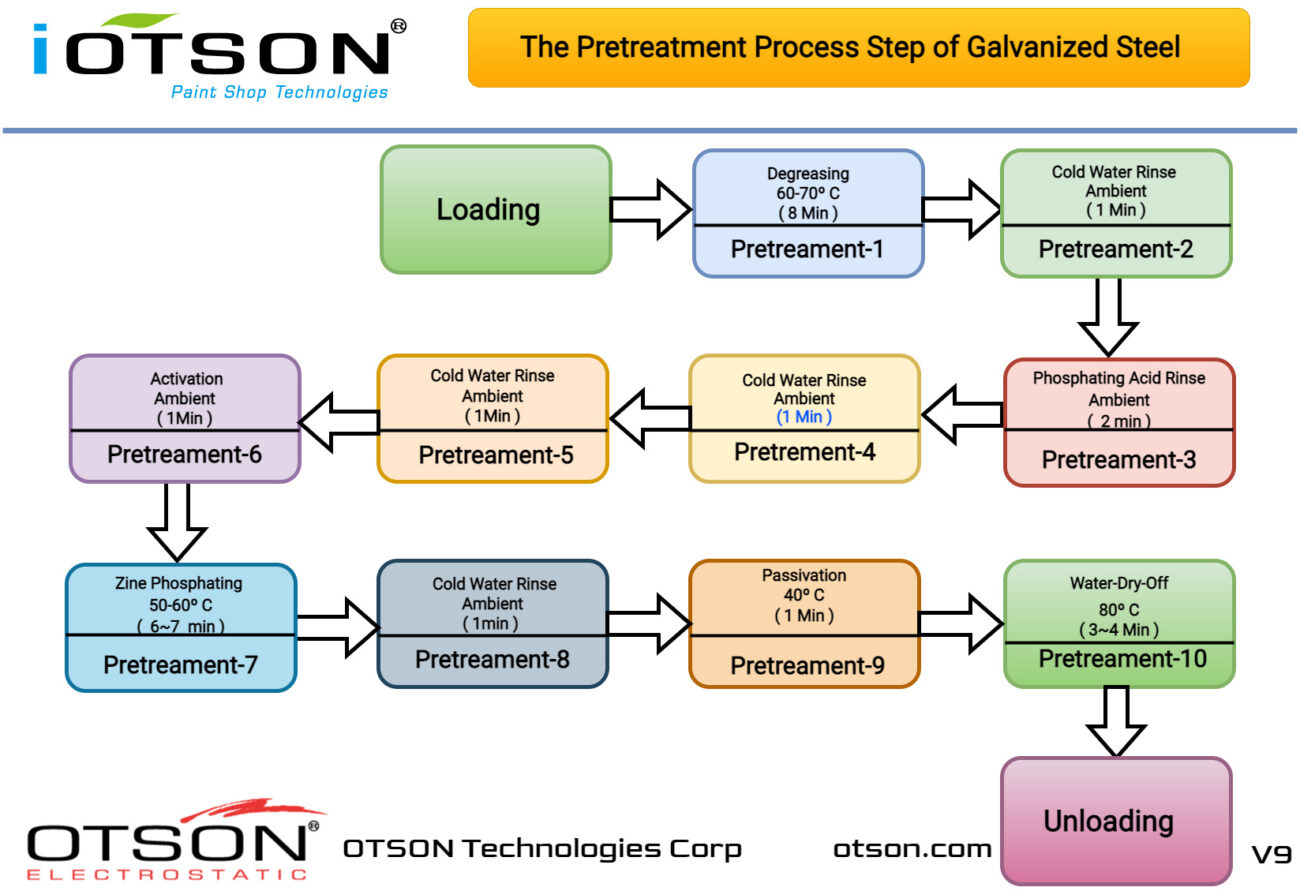

Our surface preparation process includes the following steps:

- Cleaning: We use solvents, detergents or other cleaning agents to remove dirt, oil, and other contaminants from the surface.

- Degreasing: We use solvents or chemical cleaners to remove oils and other contaminants.

- Sanding or grinding: We use abrasive materials to remove rust, scale, or other imperfections from the surface.

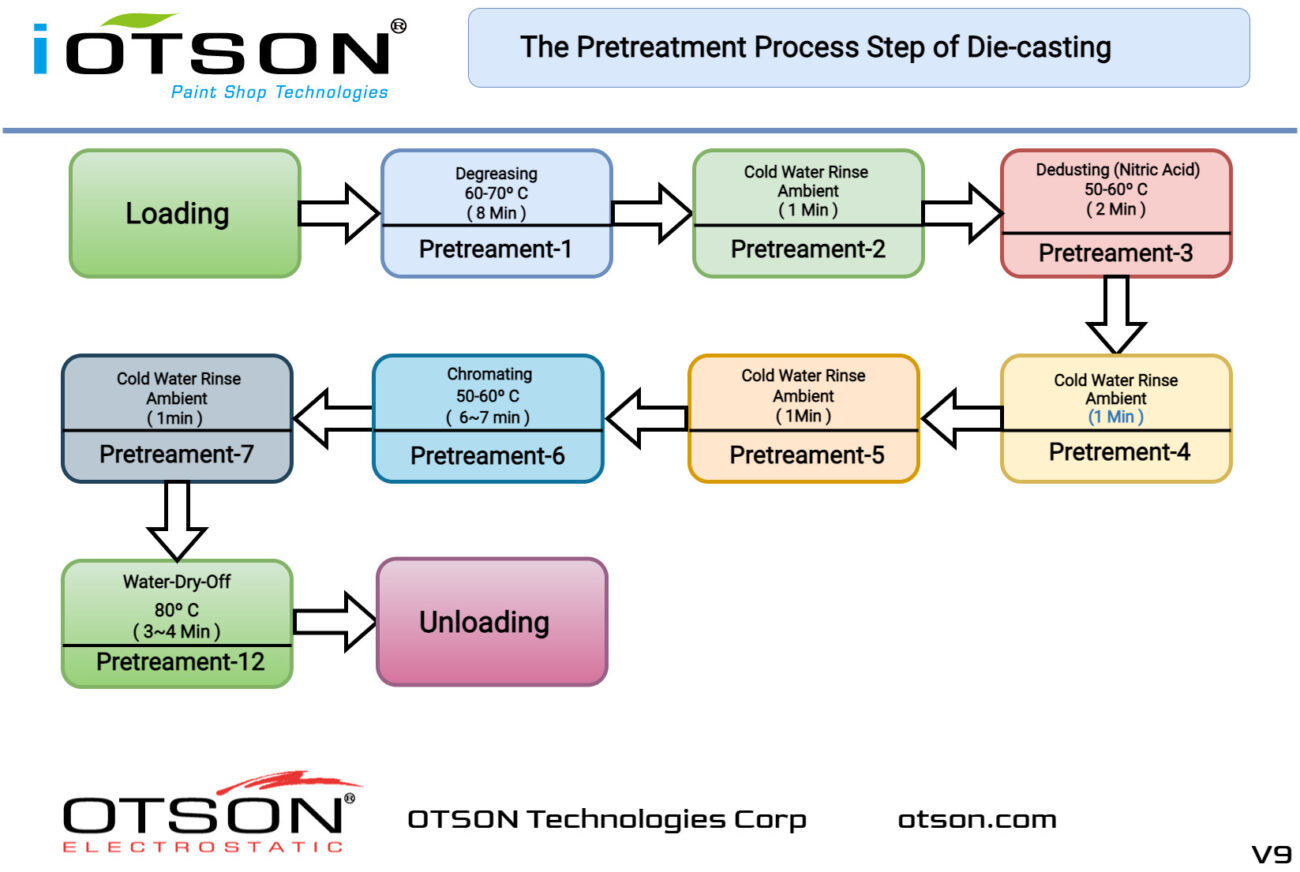

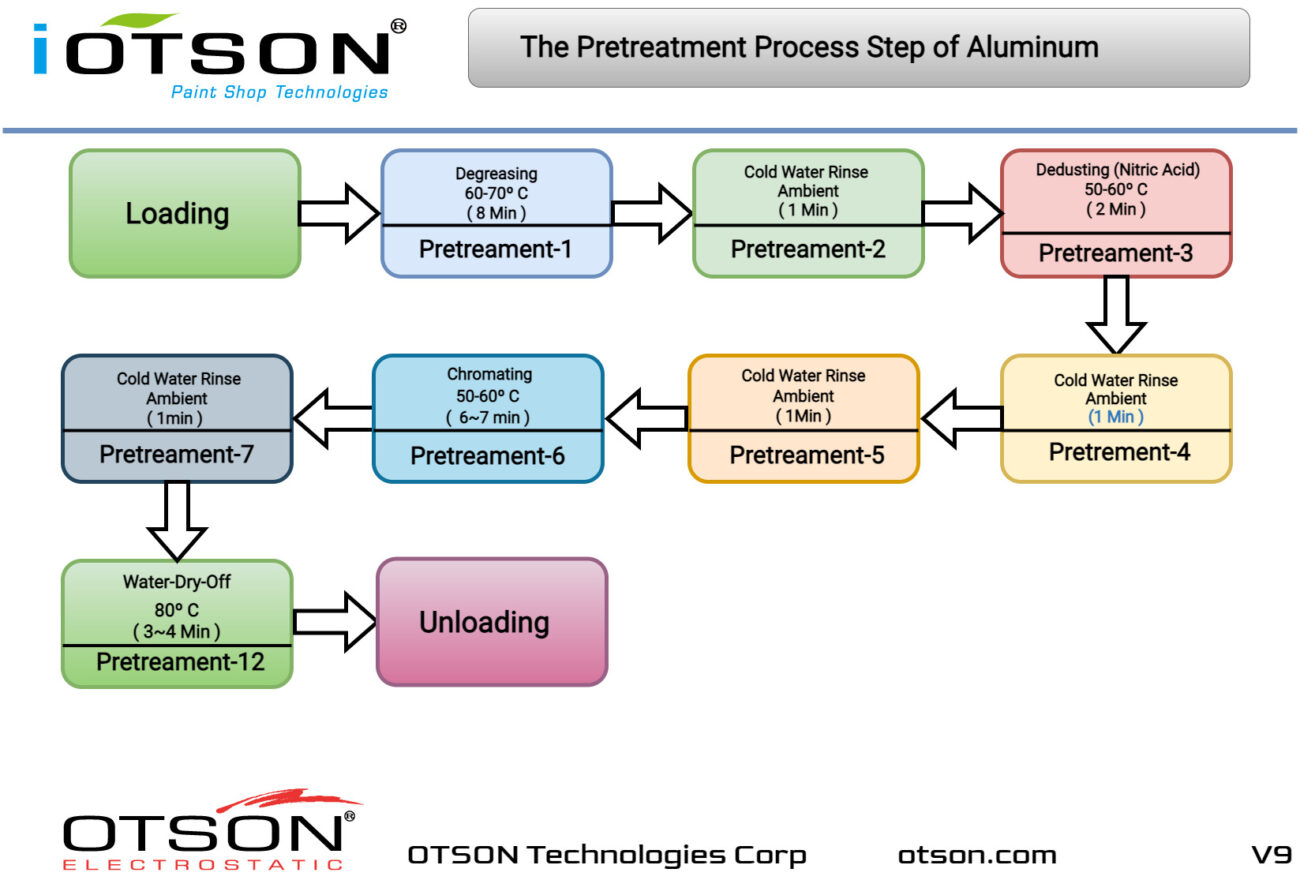

- Etching: We use acid or other chemical solutions to create a rough surface texture that helps the coating material adhere better.

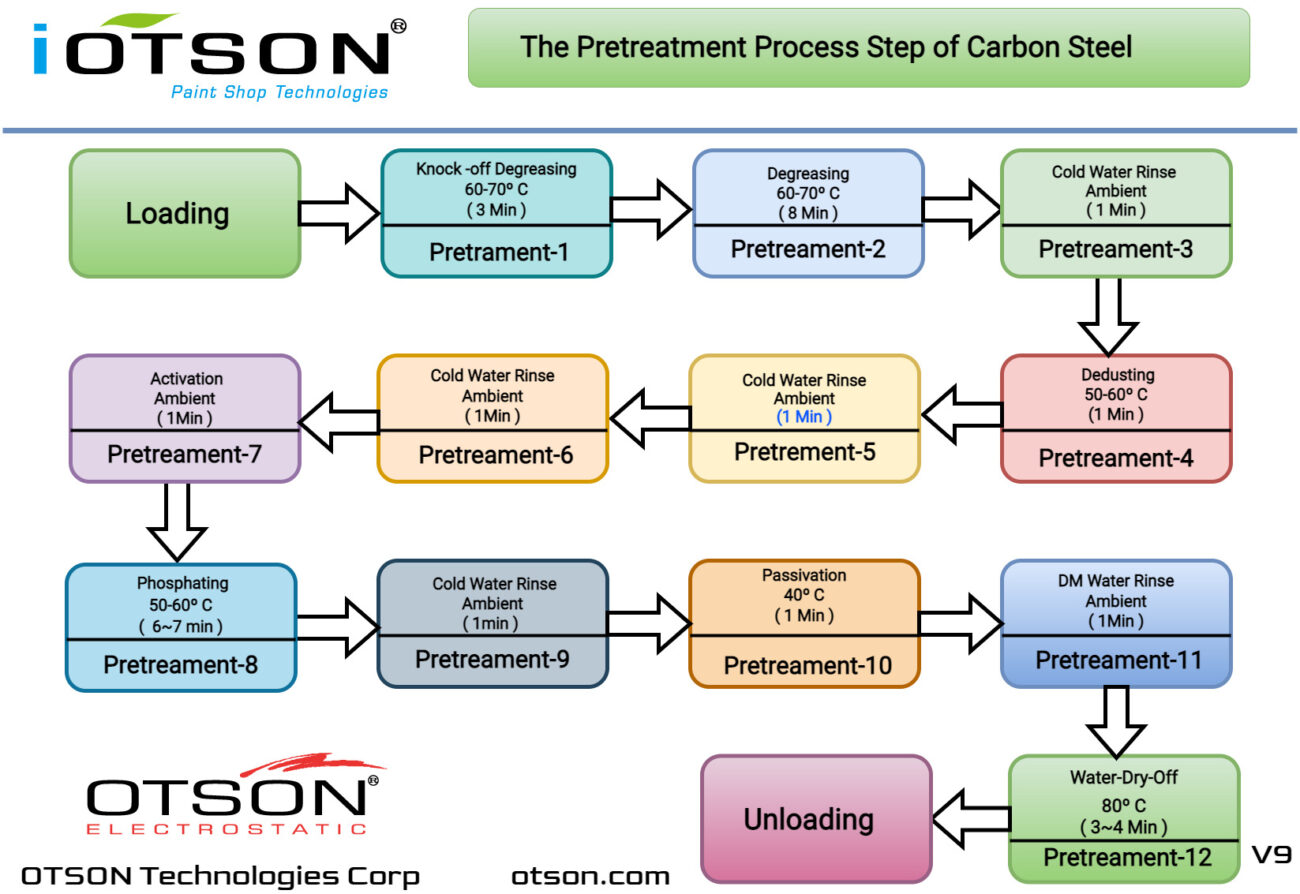

- Phosphating: We apply a chemical solution to create a thin, porous layer on the surface that helps the coating material adhere better.

- Rinsing: We rinse the surface with water to remove any residue from the pretreatment process.

- Drying: We allow the surface to dry completely before the coating process begins.

Our team of experts can customize the surface preparation process of the paint shop to meet the specific requirements of your project, and we use the latest equipment and technology to ensure that your surface is ready for electrostatic spray coating. Our surface preparation process is done in compliance with safety guidelines and the proper PPE is always worn.

We are committed to providing our customers with a comprehensive and high-quality service. Contact us today to learn more about how we can help with your surface preparation and electrostatic spray coating needs.

Finally, it is also important to make sure that the electrostatic spray equipment is properly calibrated and maintained, and that the paint being used is compatible with the glass surface.

Additionally, by choosing OTSON’s electrostatic spray system, as a part of OTSON Technologies, a professional paint shop manufacturer, you can benefit from the following advantages:

- Increased Efficiency: OTSON’s electrostatic spray systems are designed to increase the efficiency of the painting process, resulting in higher production rates and lower costs.

- Improved Quality: The precise application of paint provided by OTSON’s electrostatic spray systems can result in a higher-quality finish with fewer defects.

- Enhanced Safety: OTSON’s electrostatic spray systems are designed with safety in mind, minimizing overspray and minimizing the need for manual touch-ups.

- Customizable Solution: OTSONTechnologies can provide a customized solution tailored to your specific needs and requirements.

- Trusted Brand: OTSONTechnologies is a well-established brand in the industry, known for its high-quality products and excellent customer service.