OTS-8100 Auto Electrostatic Spray Gun kit

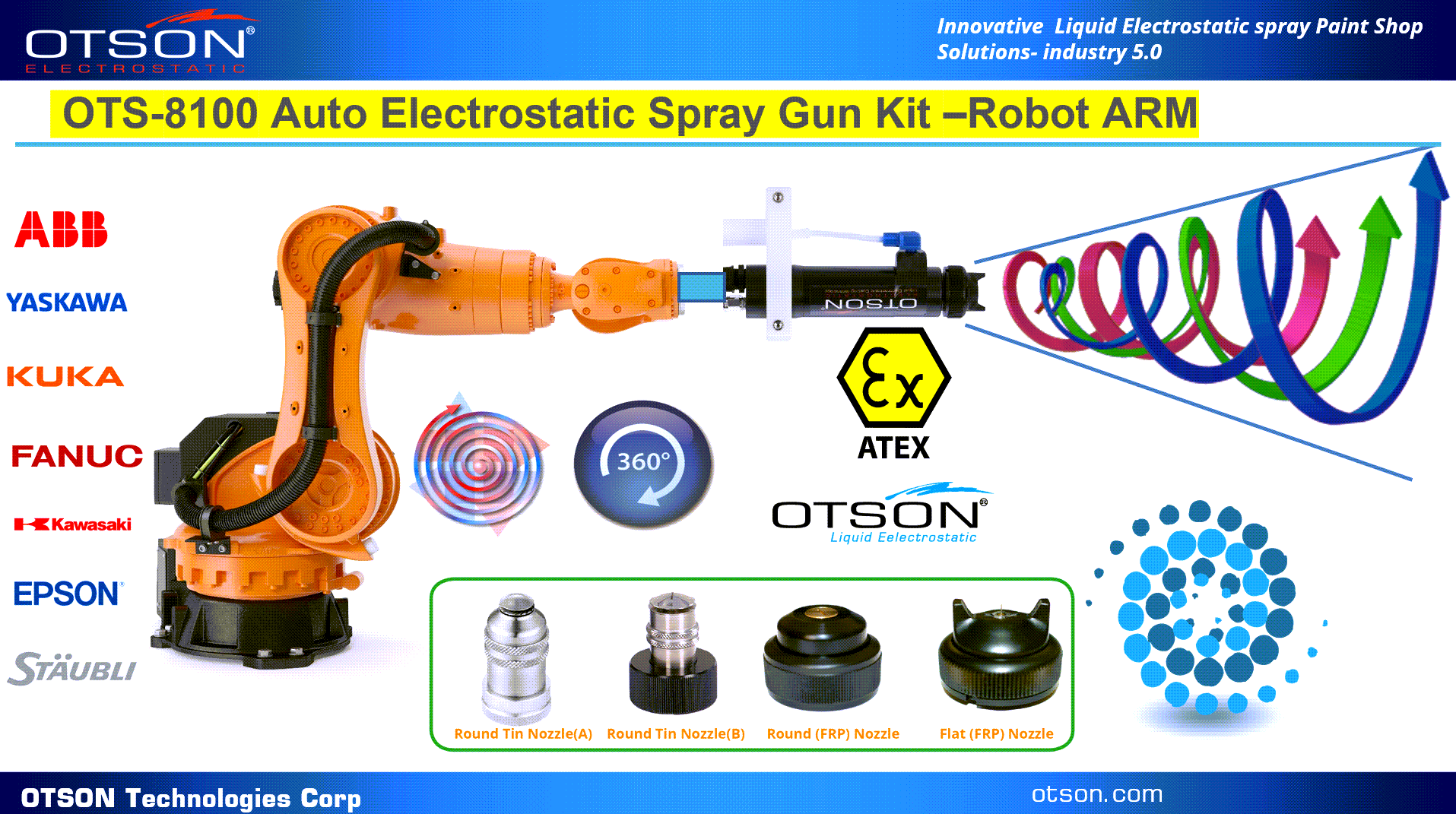

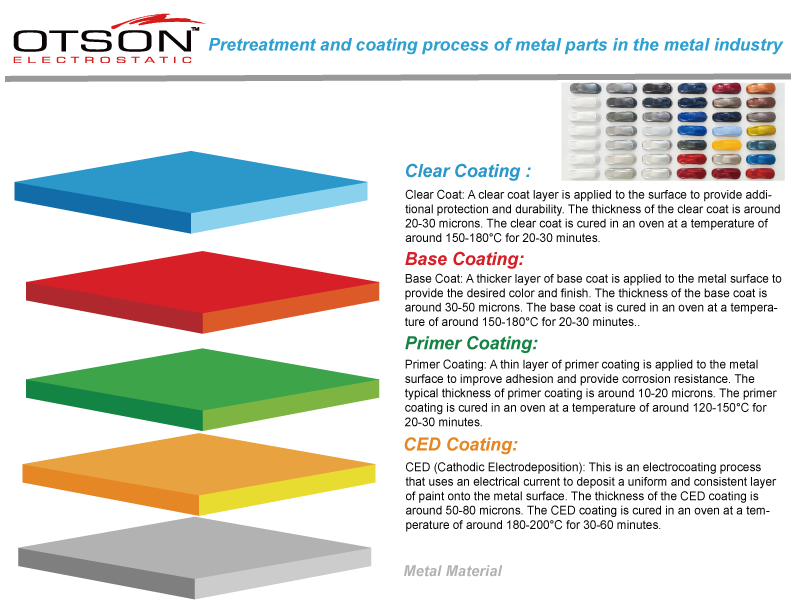

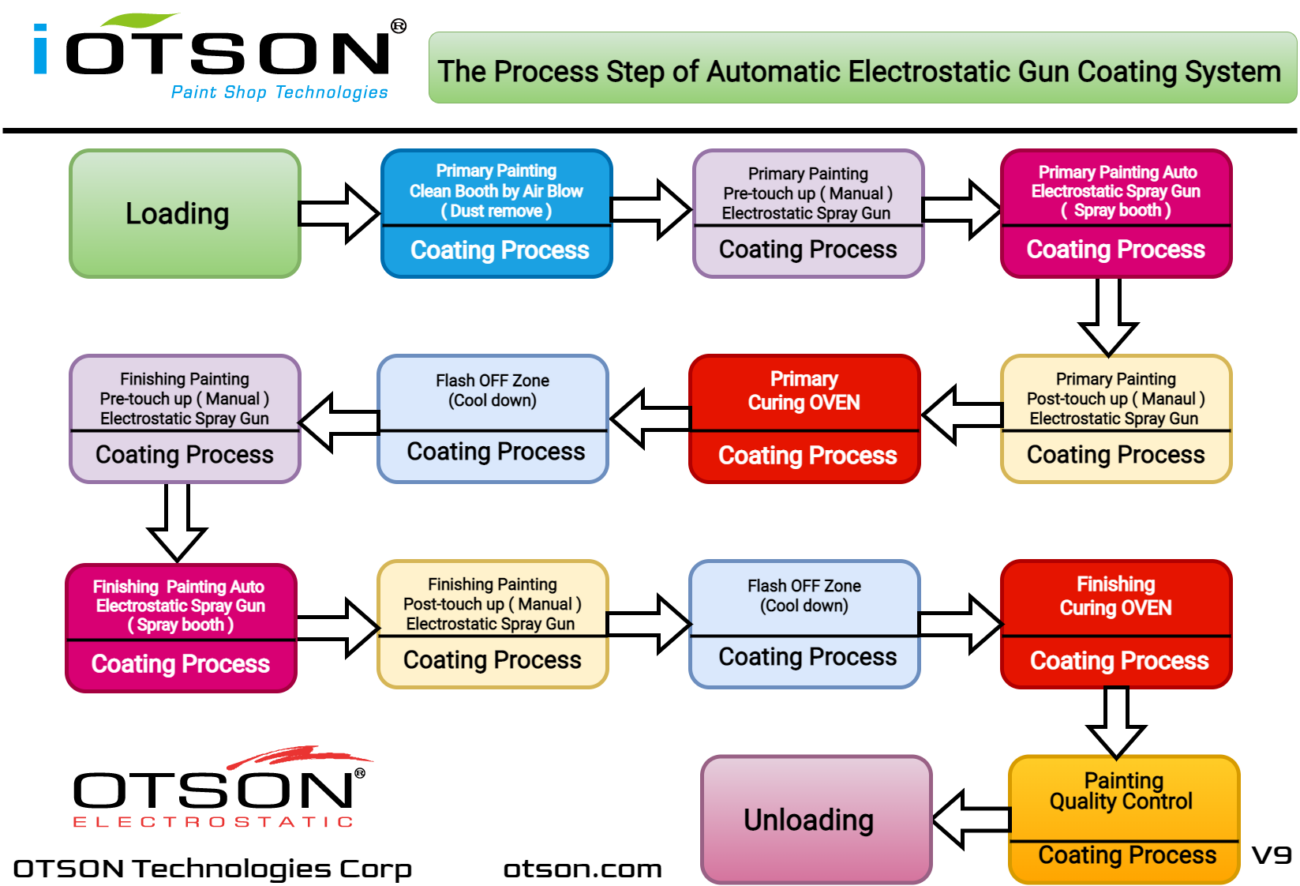

The OTS-8100 Auto Electrostatic Spray Gun is a cutting-edge solution for applying coatings and paints efficiently. This gun is designed to be used in conjunction with a robot arm, making it ideal for automated industrial painting and coating applications. The OTS-8100 is compatible with any brand of robot arm system, making it a versatile option for a wide range of industries.

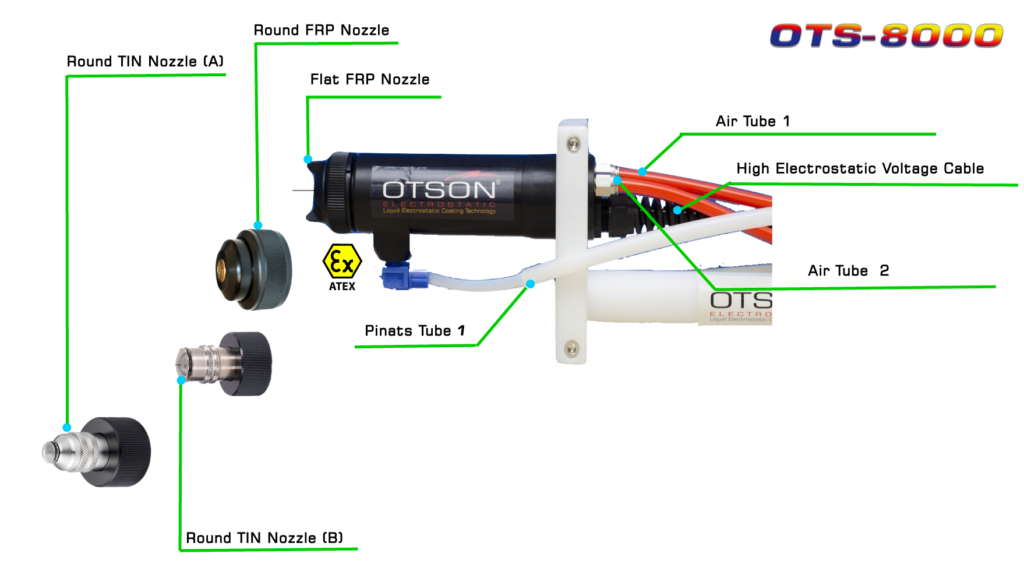

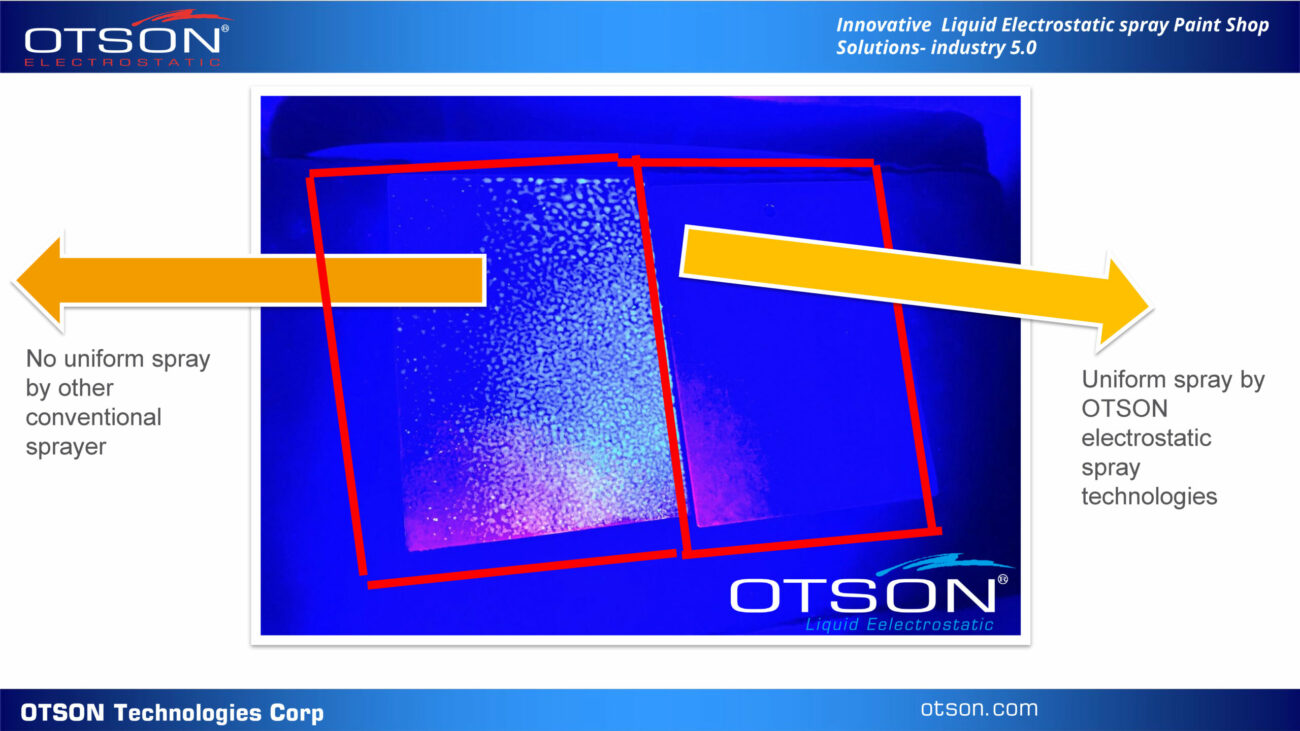

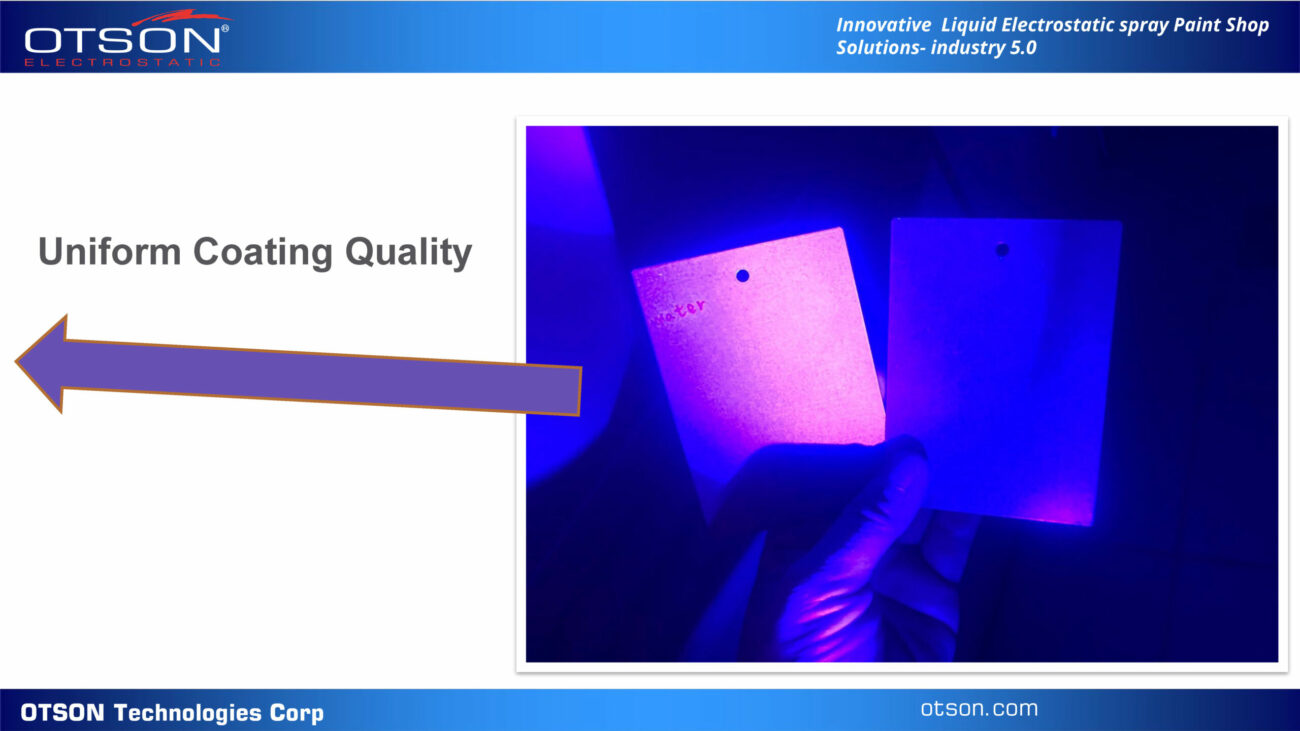

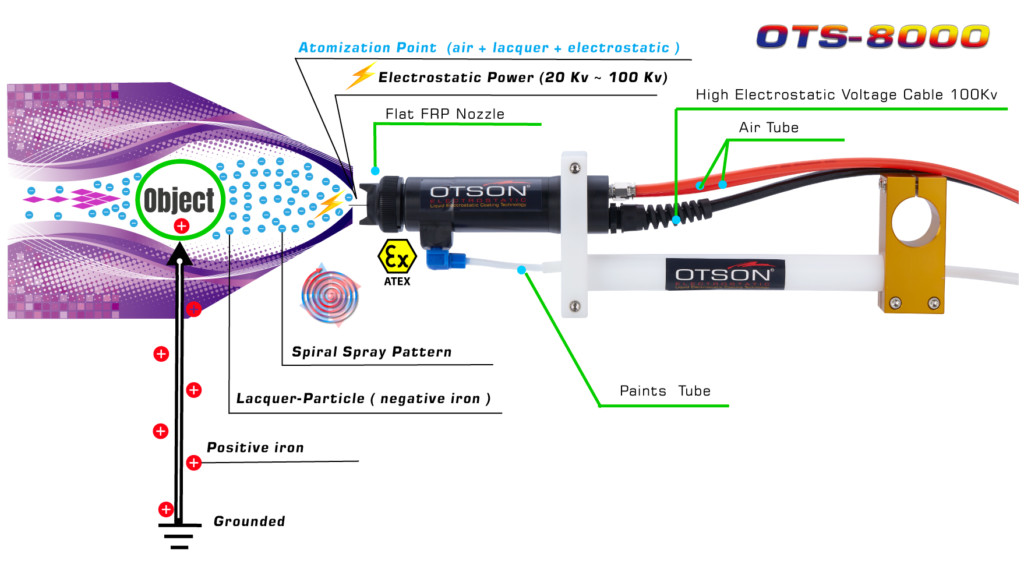

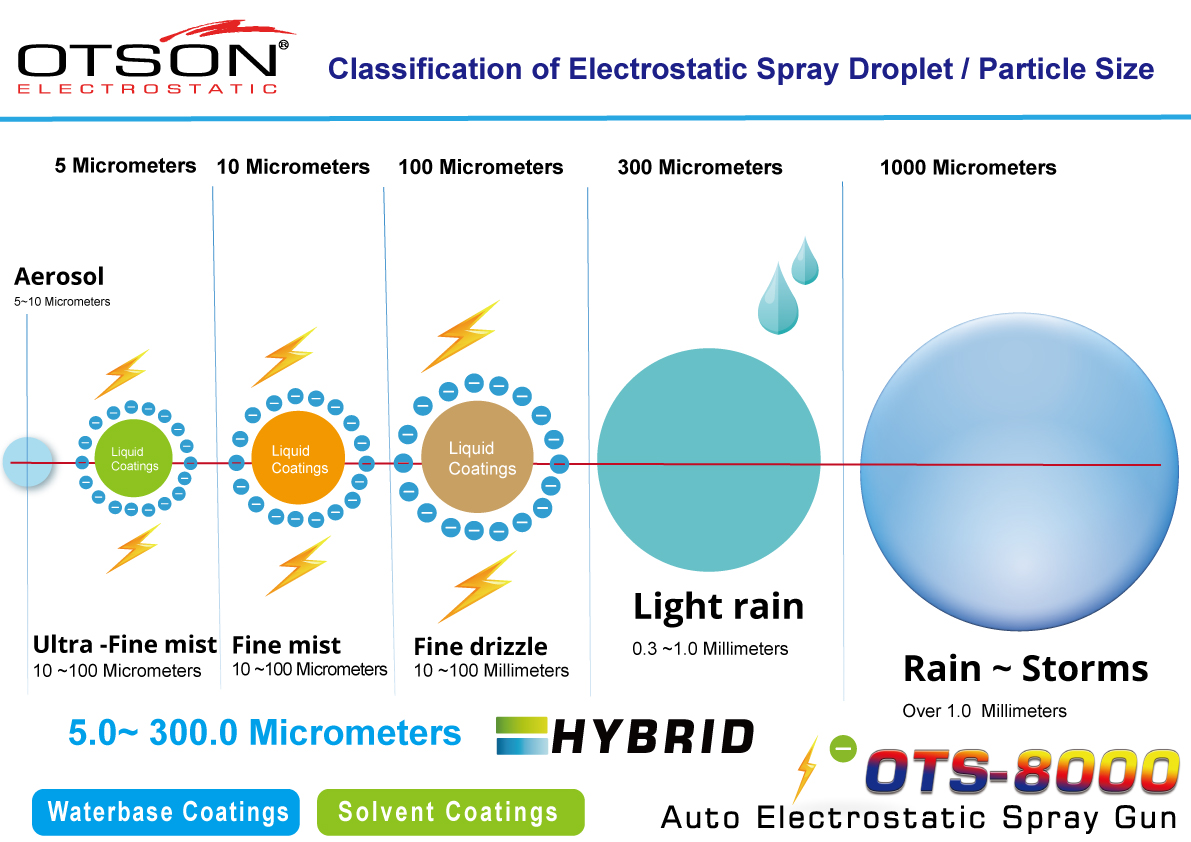

Auto liquid electrostatic spray systems, like the OTS-8100, rely on air or high pressure to atomize the coating material. The particles of the coating are then charged as they exit the nozzle. Different air nozzles and caps, which create different spiral spray patterns, are available for OTSON liquid electrostatic spray guns. This spiral effect reduces coating-particle velocity, resulting in a more uniform atomization. The technique involves applying a charge, usually negative, to the coating material as it is atomized. The negatively charged spray droplets are attracted to any grounded surface, resulting in a more consistent and higher-quality finish. This effect is so powerful that, with some objects, coating spray can be observed to ‘wrap around’.

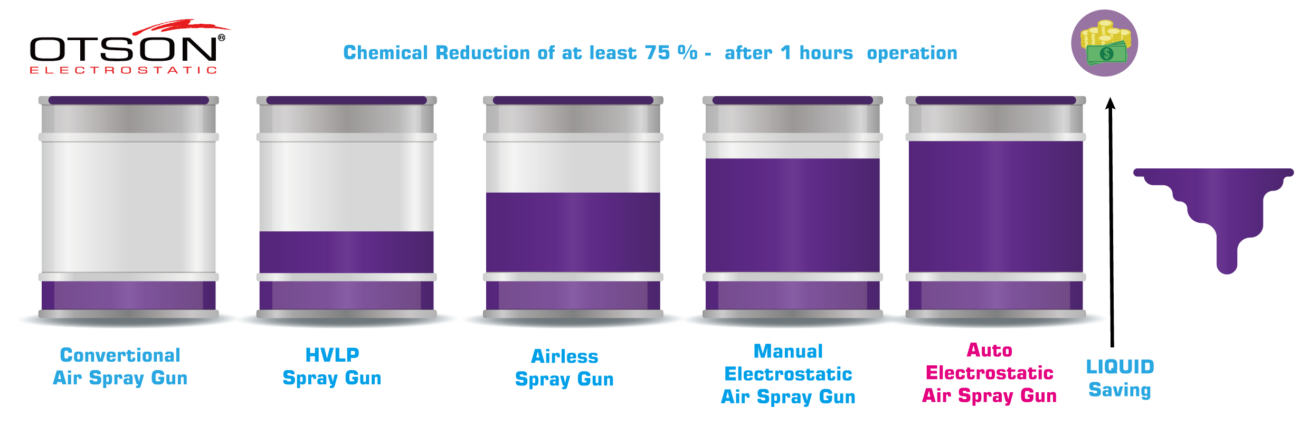

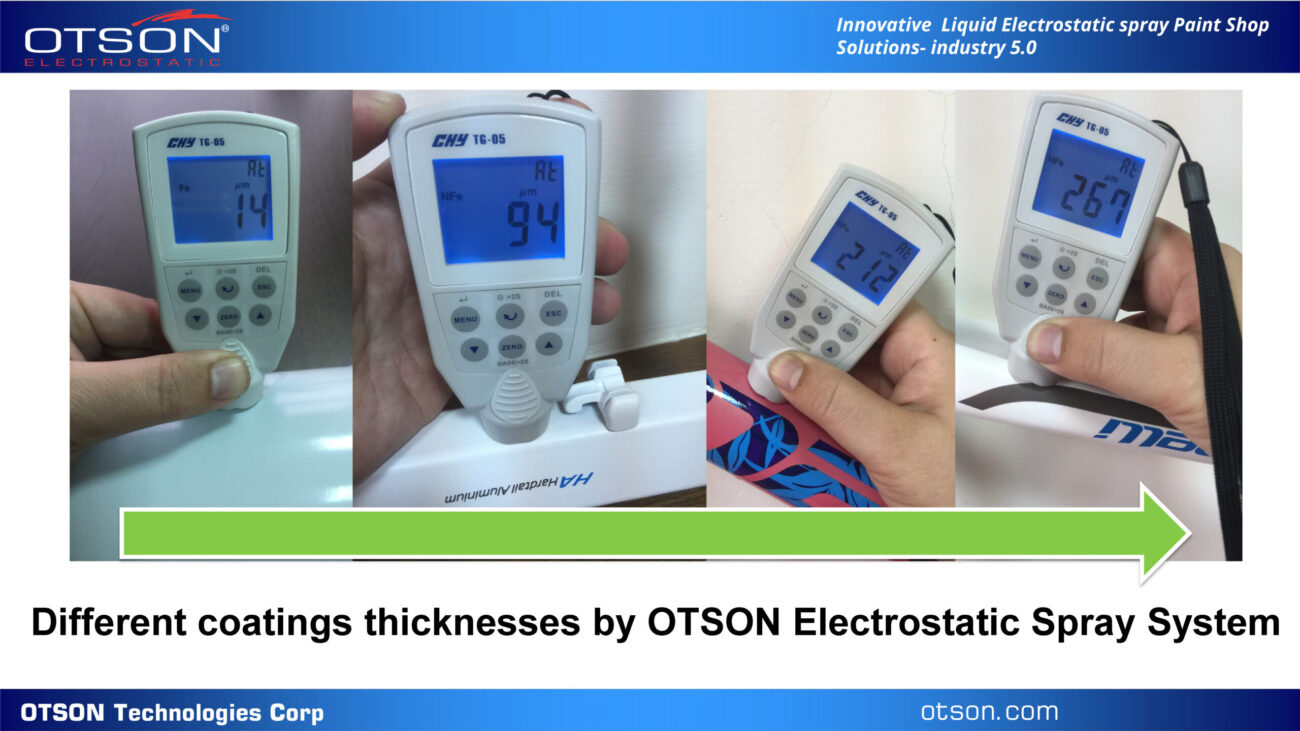

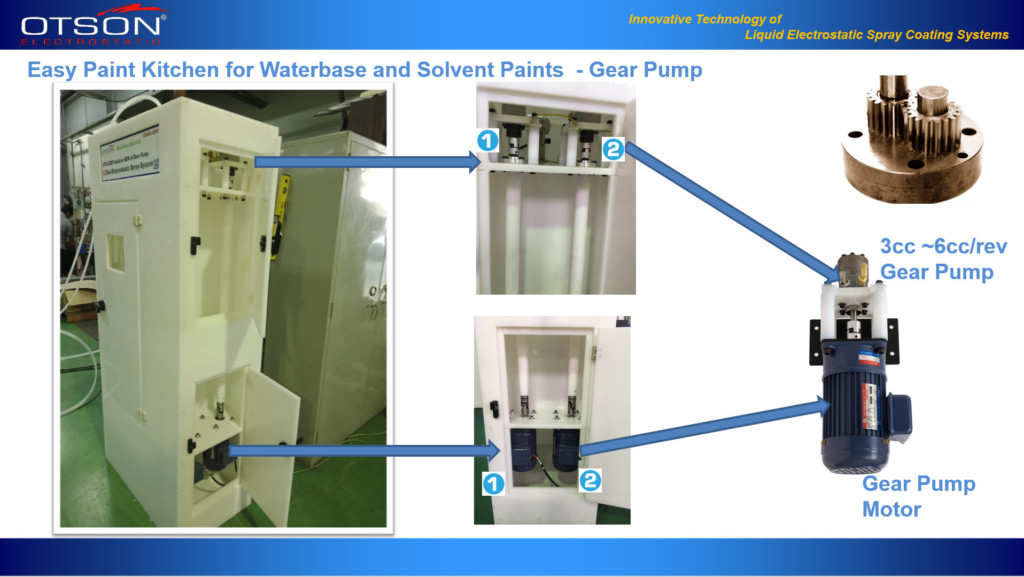

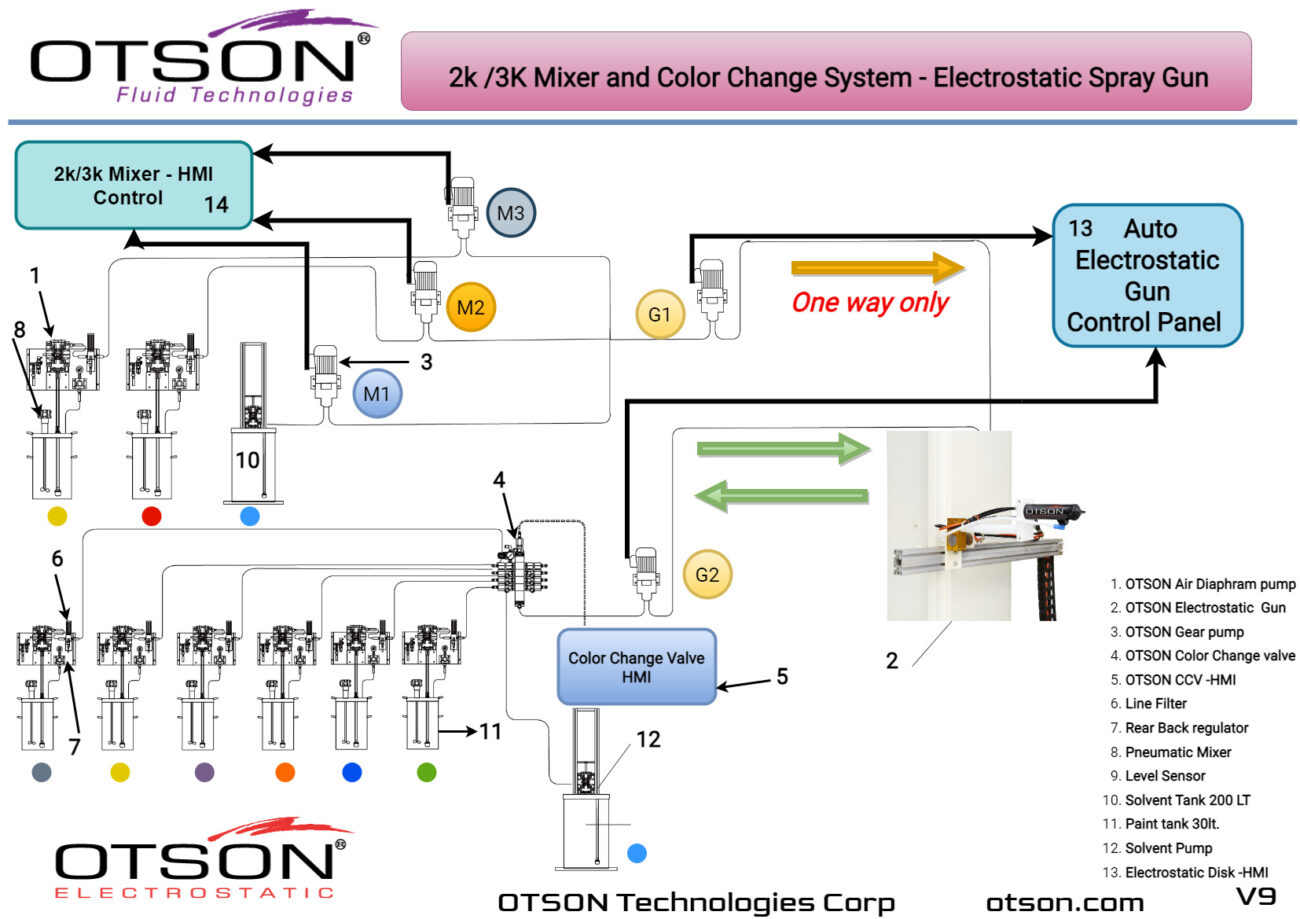

The OTS-8100 can offer transfer efficiency up to 95% and minimize overspray. Additionally, it has an auto-color change function, which allows for easy switching between different coating colors without the need for manual intervention. OTSON has been researching and developing electrostatic equipment for over 30 years and our technology can now also be used for waterborne and 2K paints, as well as solvent-based paints and lacquers. Our systems also have ATEX certification, ensuring compliance with safety regulations in potentially explosive environments.

In summary, the OTSON OTS-8100 Auto Electrostatic Spray Gun is a cutting-edge solution for applying coatings and paints efficiently, with a high transfer efficiency that results in a higher-quality finish. The design of our system allows for easy maintenance and the use of a wide range of coatings and paints, including those used in automotive, industrial and marine applications. Additionally, the auto-color change function allows for easy switching between different coating colors. OTSON is committed to providing the best solutions for customers’ specific requirements, and our team of experts is ready to help with the integration and optimization of our electrostatic spray gun systems in their processes.