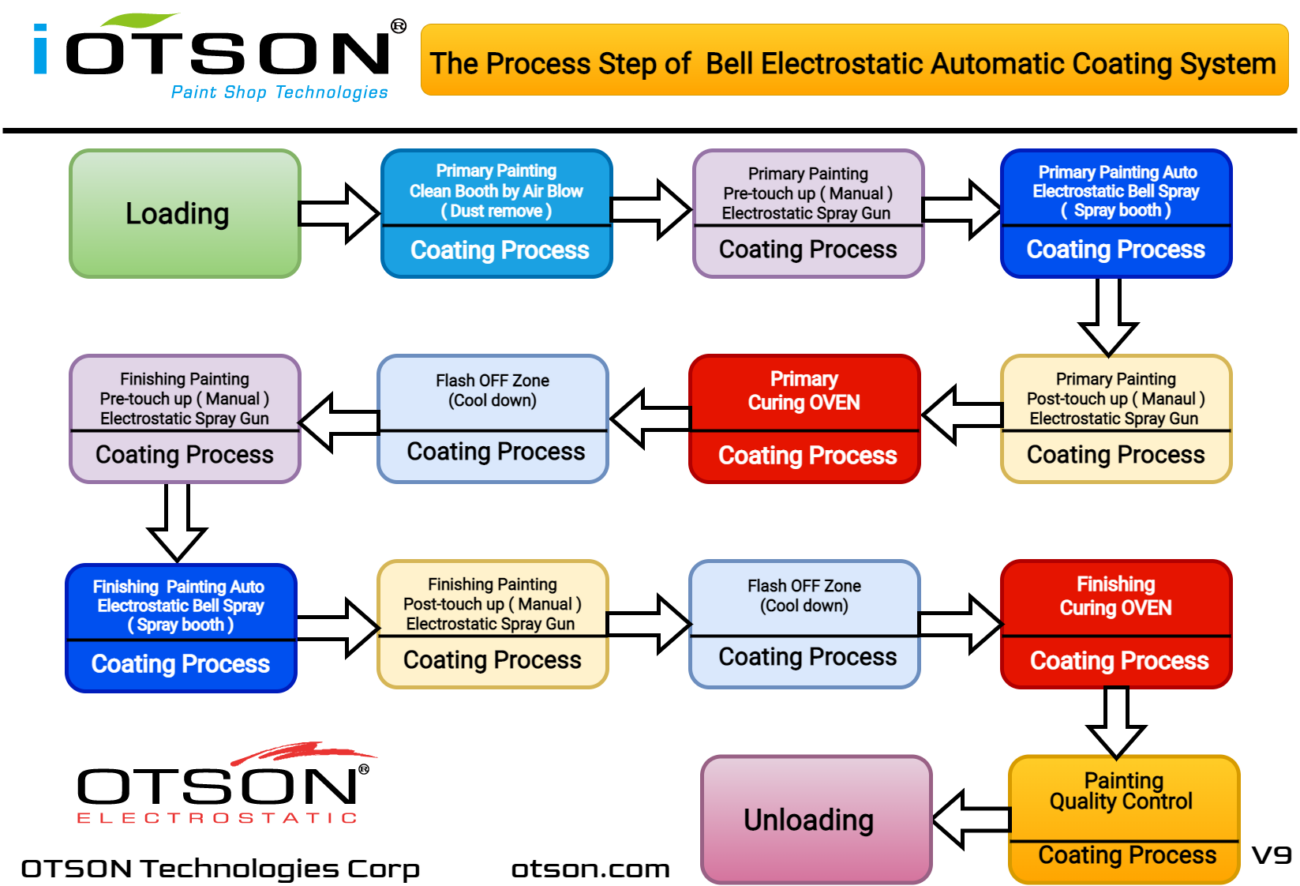

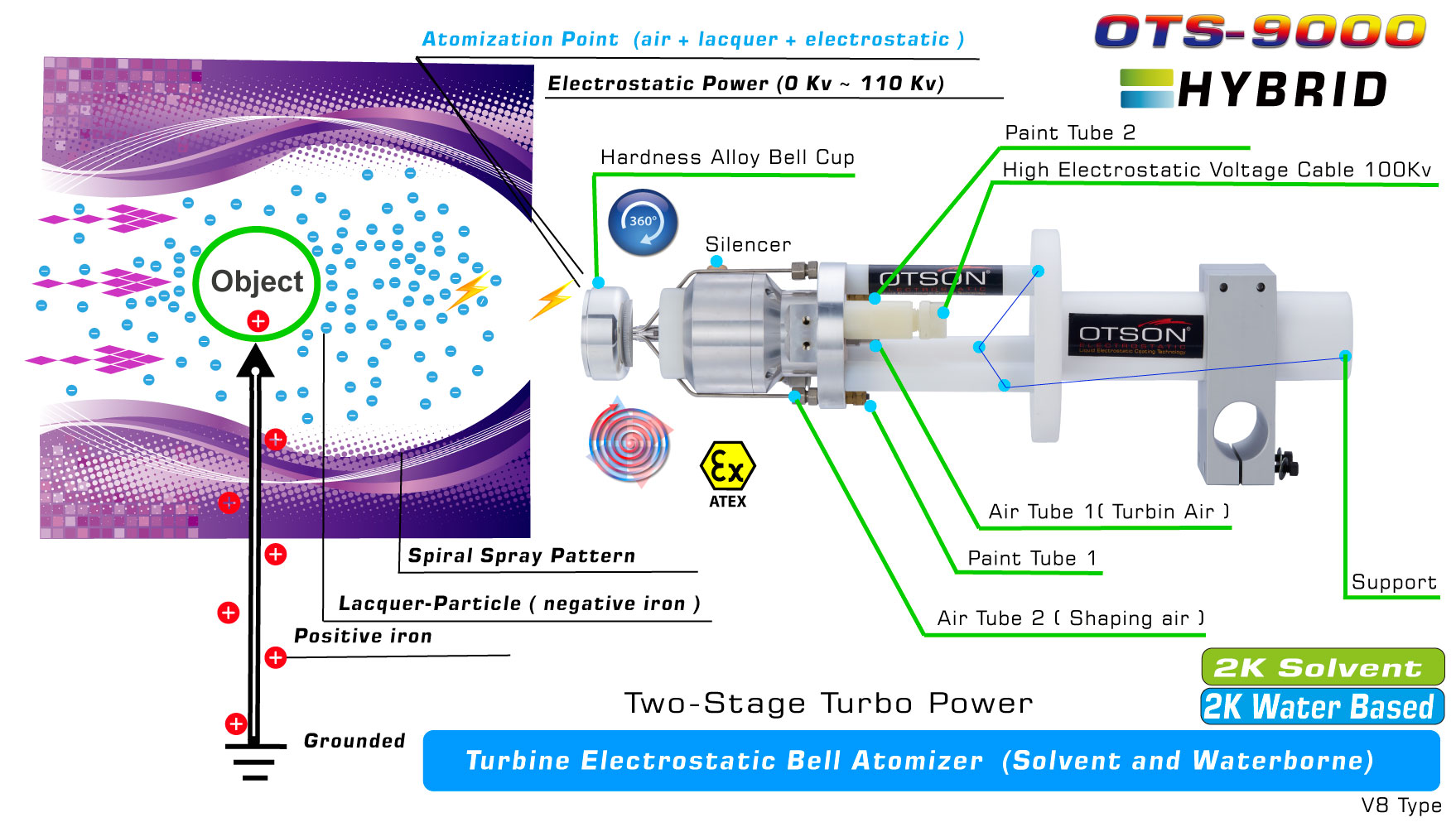

An electrostatic spray bell system is a type of spray coating system that uses an electrostatic charge to apply a coating material to a surface. In an electrostatic spray bell system, the coating material is atomized into fine droplets and then charged with an electrical current. The charged droplets are then attracted to the surface being coated, allowing for more precise application and a more even finish

.

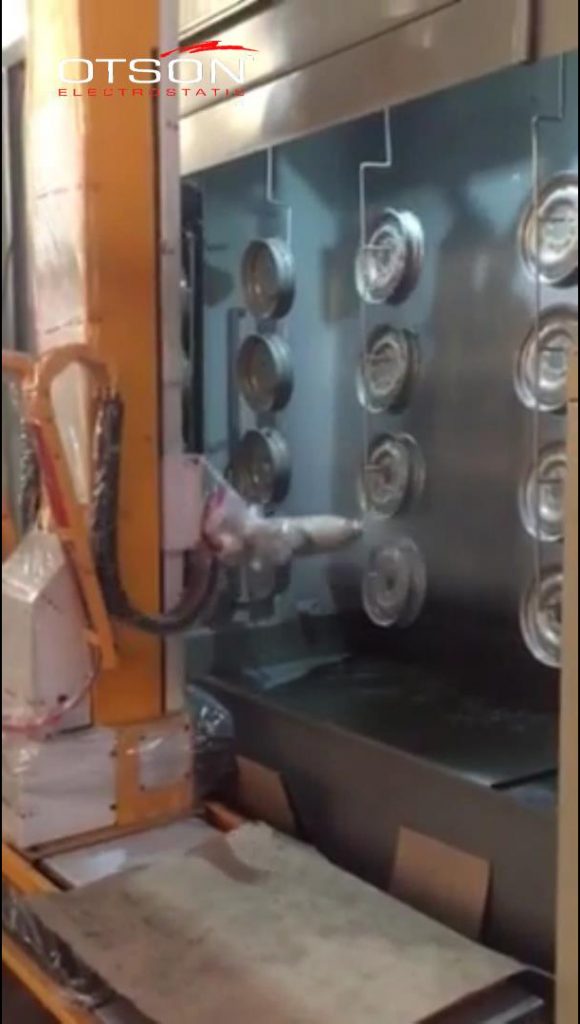

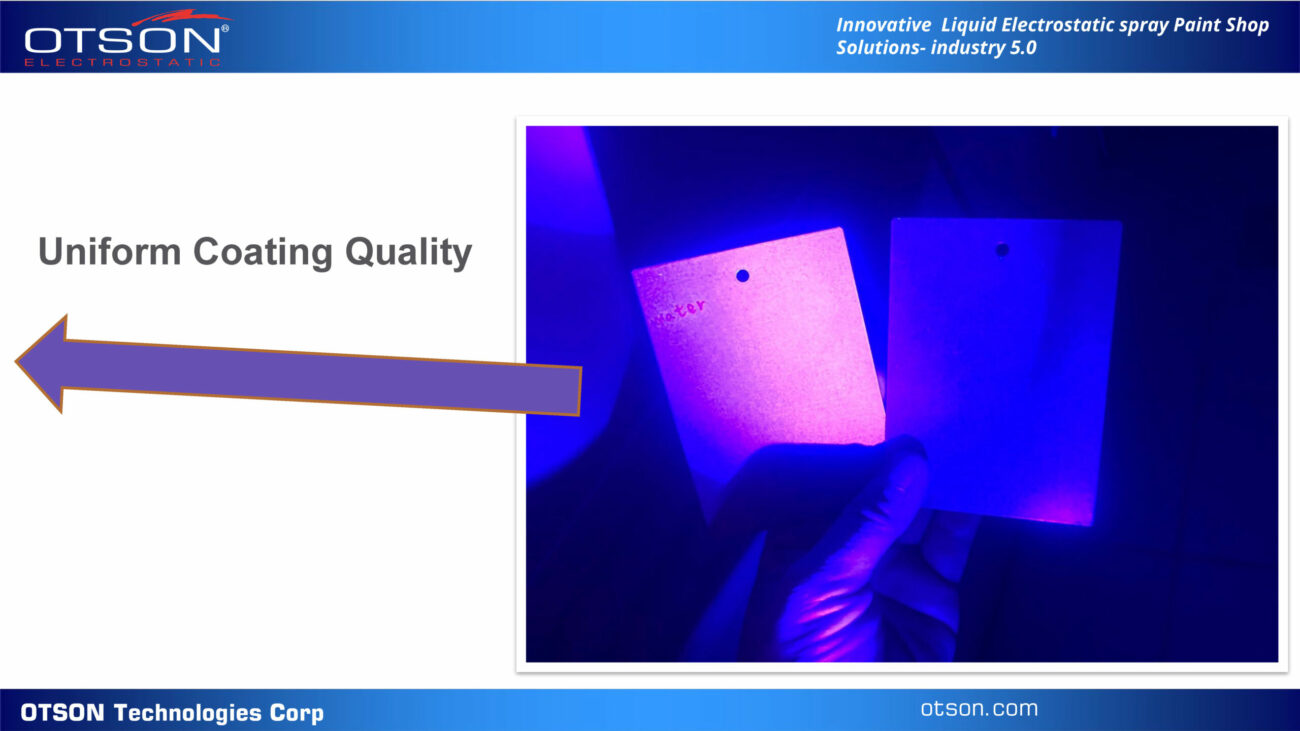

The spray bell itself is a device that is mounted above the surface being coated and generates an electrostatic field. The charged droplets are sprayed through the bell and are attracted to the surface below. The shape of the bell allows for the coating material to be applied evenly and uniformly over the surface.

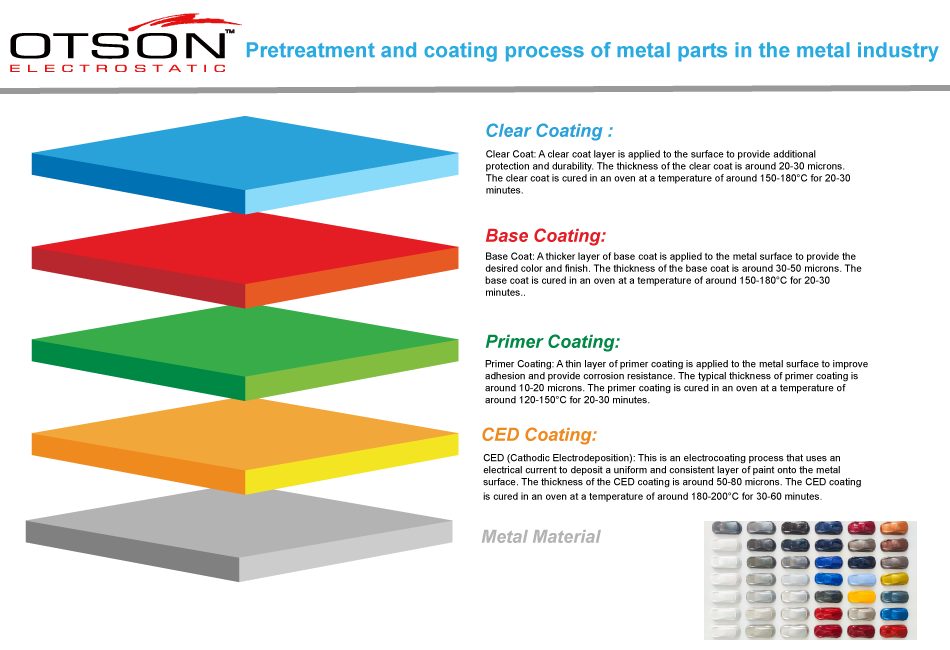

Electrostatic spray bell systems are often used in a variety of industries, including automotive, aerospace, and manufacturing, to apply paints, coatings, and other finish materials. They can be used to coat a wide range of surfaces, including metal, plastic, and composite materials.

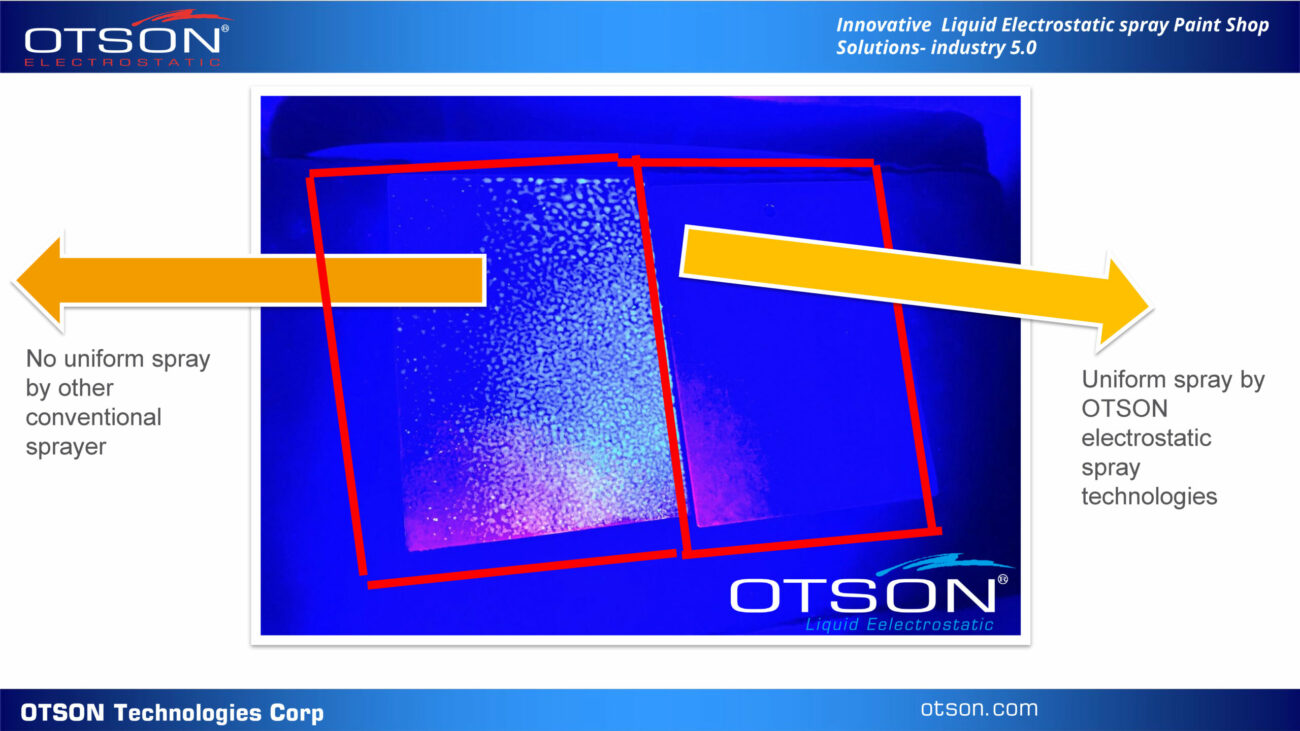

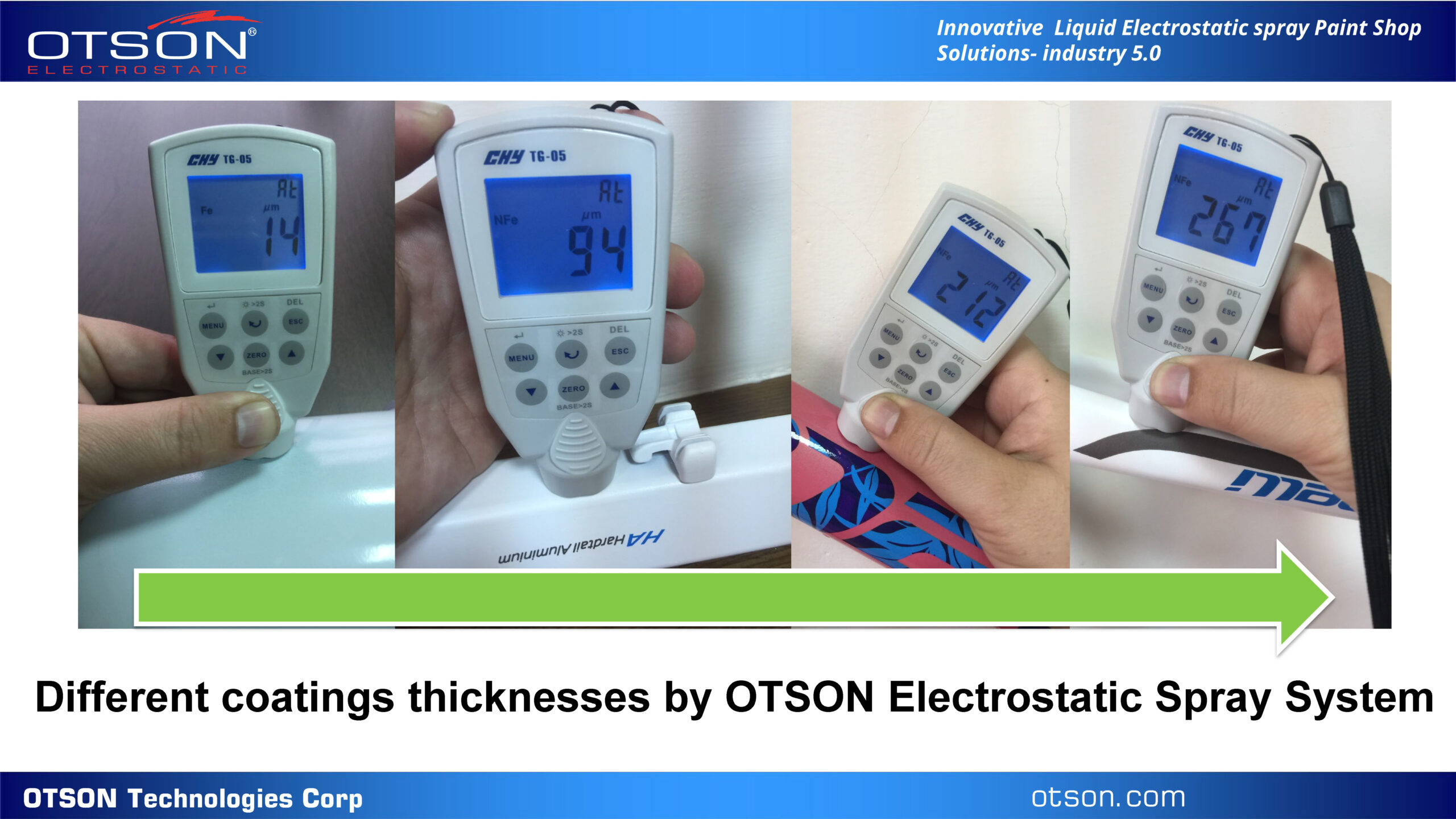

Electrostatic spray bell systems have several advantages over traditional spraying methods, including improved precision, reduced overspray, increased efficiency, and better transfer efficiency. They also offer greater control over the coating process and can be more environmentally friendly, as they often produce fewer volatile organic compounds (VOCs) compared to other coating methods.

An electrostatic spray bell system is a type of spray coating system that uses an electrostatic charge to apply a coating material to a surface. Here is a more detailed explanation of how it works:

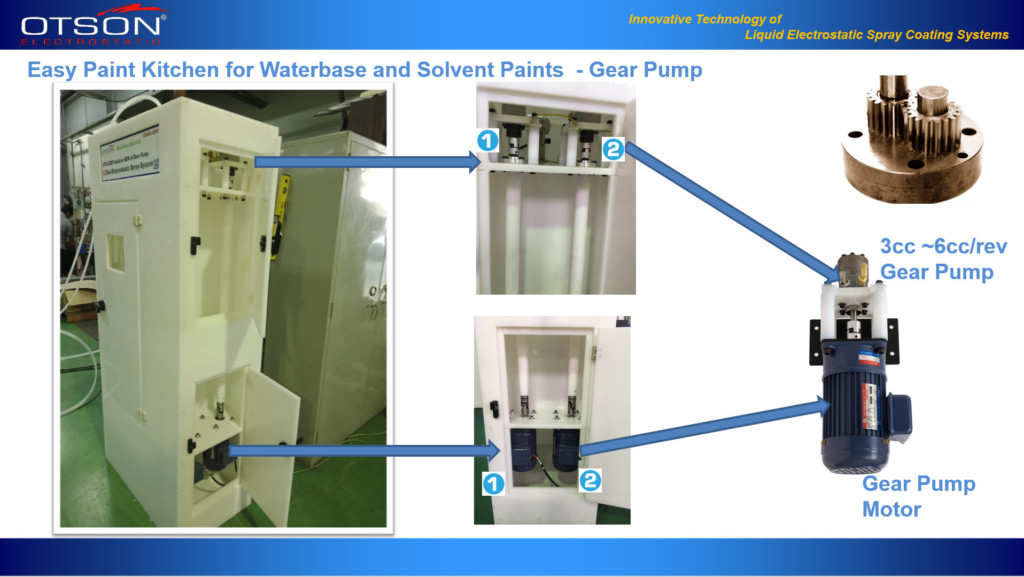

- The coating material is placed in a container, such as a tank or a hopper, and is then pressurized using air or another gas.

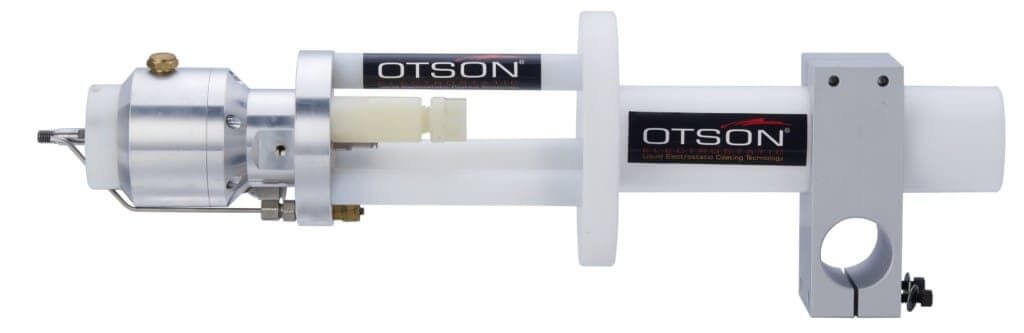

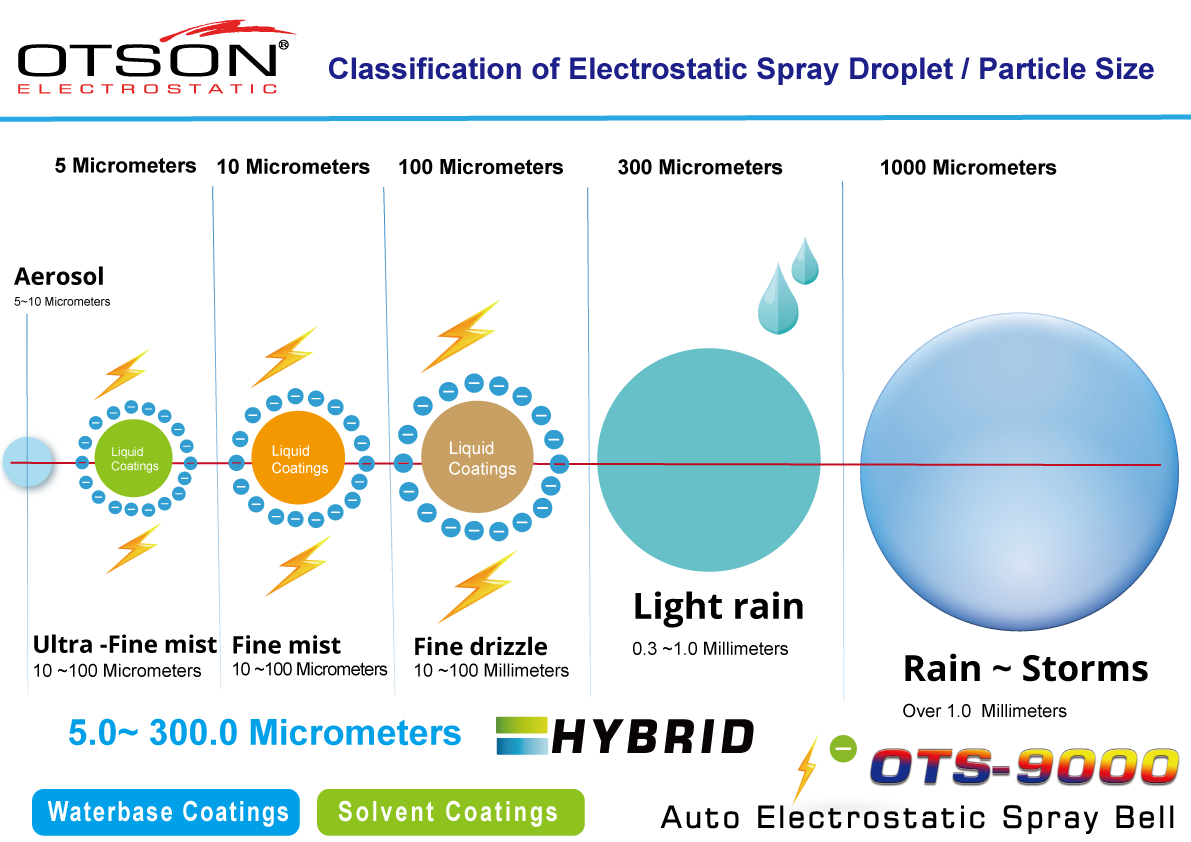

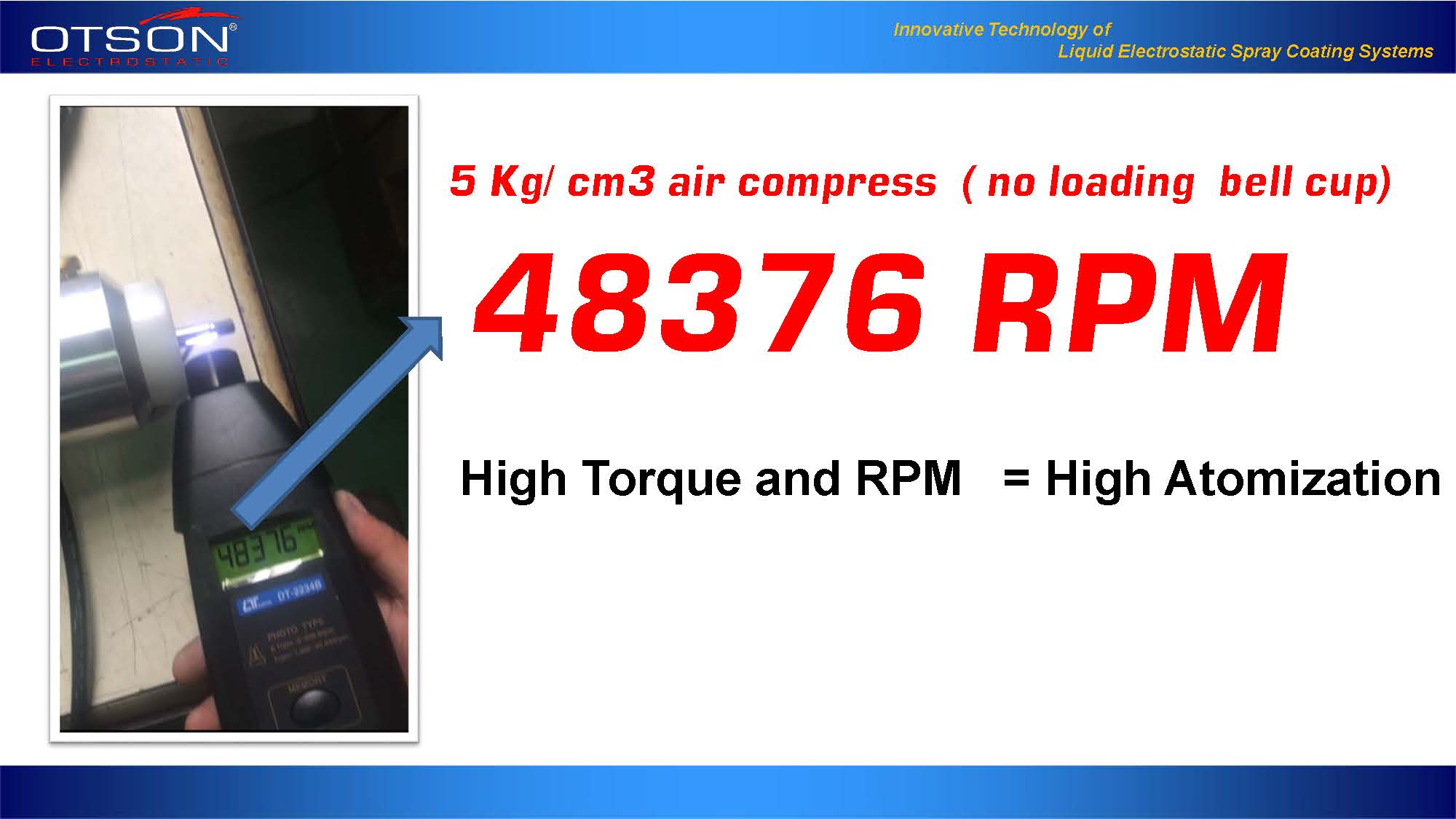

- The pressurized coating material is then passed through a nozzle, which atomizes it into fine droplets.

- An electrical current is then applied to the droplets, causing them to become charged.

- The charged droplets are then sprayed through a bell-shaped device mounted above the surface being coated. The bell generates an electrostatic field, which attracts the charged droplets to the surface.

- The shape of the bell allows for the coating material to be applied evenly and uniformly over the surface.

Electrostatic spray bell systems are often used in a variety of industries, including automotive, aerospace, and manufacturing, to apply paints, coatings, and other finish materials. They can be used to coat a wide range of surfaces, including metal, plastic, and composite materials.

Electrostatic spray bell systems have several advantages over traditional spraying methods, including improved precision, reduced overspray, increased efficiency, and better transfer efficiency. They also offer greater control over the coating process and can be more environmentally friendly, as they often produce fewer volatile organic compounds (VOCs) compared to other coating methods.