In the realm of modern manufacturing, innovation continues to revolutionize industries such as automotive, aerospace, and woodworking. One groundbreaking technology that has significantly impacted the paint shop systems within these sectors is electrostatic painting. This article delves into the process and benefits of electrostatic painting, shedding light on how this advanced technique has transformed traditional painting methods.

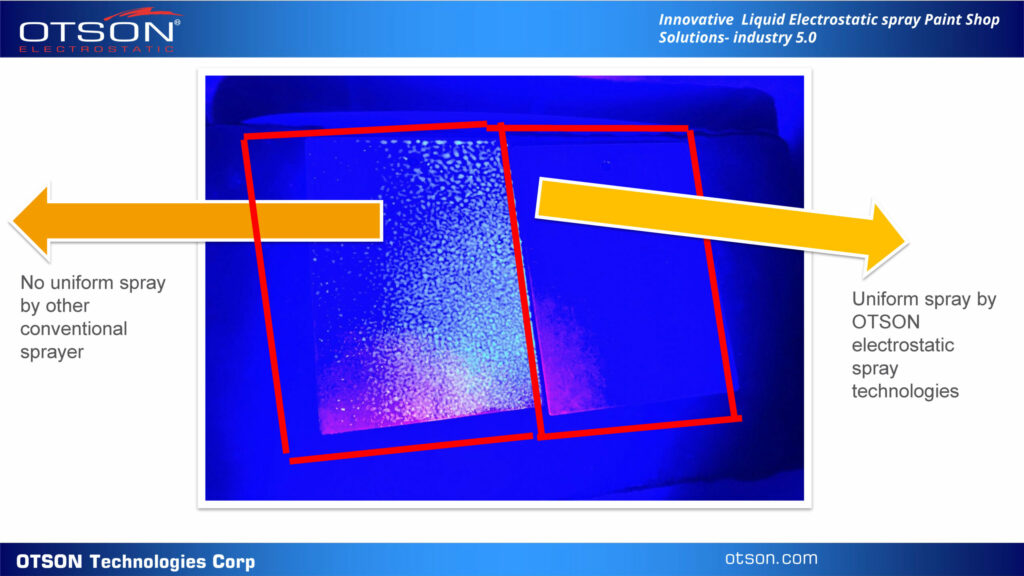

From hand-brushing to automated spray booths, the art of painting has come a long way. Traditional methods often resulted in uneven finishes, overspray wastage, and inadequate paint adhesion. However, with the advent of electrostatic painting, a new era of precision and efficiency has emerged.

How Electrostatic Painting Works

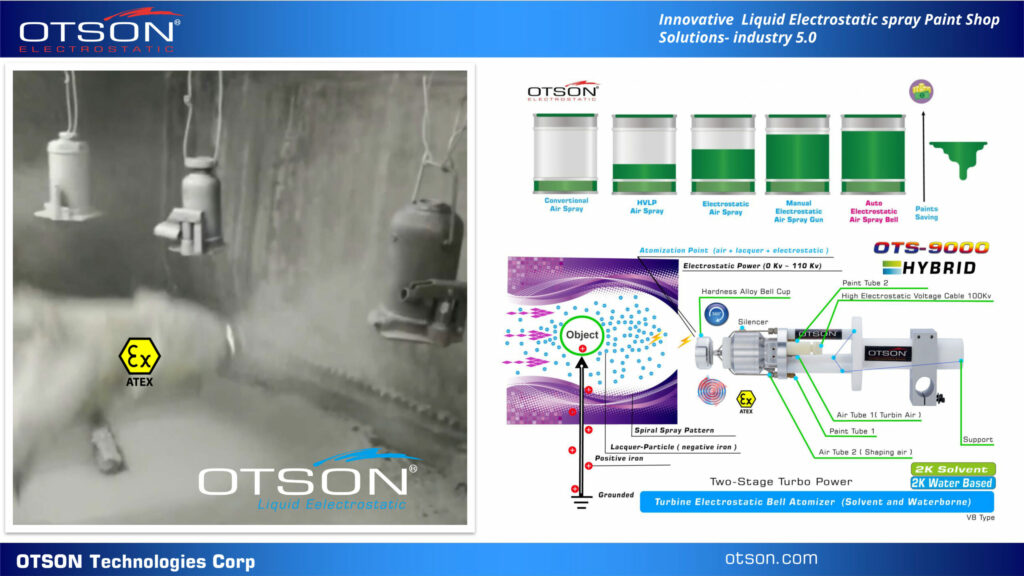

Electrostatic painting capitalizes on the fundamental principle of opposite charges attracting. The object to be painted is given a negative electric charge, while the paint particles are charged positively as they exit the spray gun. This charge differential ensures that the paint is not only drawn towards the object but also evenly coats its surface, eliminating the need for excessive paint application.

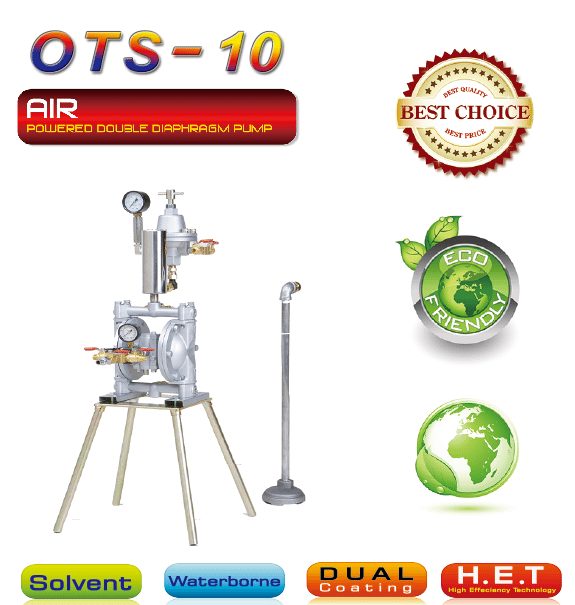

Electrostatic Spray Equipment: A Deeper Look

The heart of electrostatic painting lies in its advanced spray equipment. These systems incorporate cutting-edge technology to control factors such as paint particle size, spray pattern, and electrostatic charge intensity. This precision leads to a remarkable reduction in overspray, thus conserving paint and minimizing environmental impact.

Enhanced Paint Adhesion

Electrostatic painting results in unparalleled paint adhesion. The electrostatic attraction between the charged paint particles and the grounded object creates a bond that is exceptionally strong and uniform. This translates to coatings that adhere flawlessly even to complex shapes and difficult-to-reach areas.

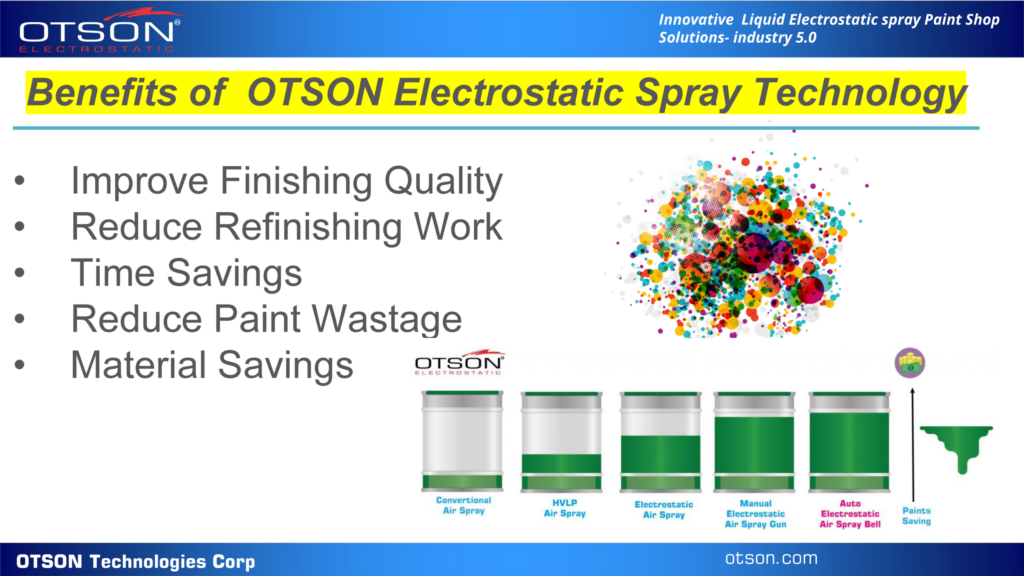

Reduced Overspray and Waste

Conventional spray methods often suffer from overspray, which not only wastes paint but also necessitates additional cleanup efforts. Electrostatic painting drastically mitigates overspray by directing the paint particles precisely where they’re needed. This reduction in waste is not only cost-effective but also environmentally conscious.

Improved Efficiency and Cost Savings

The efficiency gains of electrostatic painting are manifold. The targeted application and reduced overspray significantly cut down on paint consumption. Moreover, the ability to coat intricate parts in a single pass saves valuable production time. These factors collectively contribute to substantial cost savings over time.

CO2 Emission and Energy-Saving Technologies

In an era of heightened environmental awareness, OTSON Technologies Corp’s electrostatic painting solutions stand out for their commitment to sustainability. CO2 emission and energy-saving technologies are integrated into the paint shop systems, reducing the ecological footprint associated with painting processes.

Prioritizing Sustainability

Beyond technology, the emphasis on sustainability extends to the materials used in electrostatic painting. Water-based paints and eco-friendly coatings play a pivotal role in minimizing environmental impact without compromising on quality.

- Automotive Industry: Elevating Aesthetics and Protection From cars and trucks to buses and motorcycles, the automotive industry demands coatings that offer both aesthetics and protection. Electrostatic techniques ensure uniform coverage on complex surfaces, resulting in an appealing finish that also guards against corrosion.

- Aerospace Sector: Precision for Performance Aerospace components, such as airplanes, helicopters, and satellites, require coatings that withstand extreme conditions. Electrostatic techniques deliver the necessary precision and consistency for coating intricate components, contributing to the overall performance and durability of aerospace equipment.

- Manufacturing: Efficiency and Quality Electrostatic techniques find application in manufacturing, where machinery, tanks, and metal structures require reliable and efficient coatings. These methods ensure uniform distribution of coatings, minimizing wastage, and enhancing the longevity of industrial equipment.

- Medical Equipment: Hygiene and Precision[dt_gap height=”10″ /] In the medical field, electrostatic techniques play a pivotal role in coating equipment such as MRI machines, X-ray machines, and surgical instruments. The precision offered by these methods ensures both hygiene and the longevity of medical devices.

- Furniture and Appliances: Aesthetic Appeal and Durability Furniture pieces, as well as household appliances like refrigerators and ovens, benefit from electrostatic techniques. These methods provide consistent coating thickness, enhancing the aesthetic appeal and durability of these items.

- Marine Industry: Defying Water and Time In the marine sector, electrostatic spray coatings are essential for ships, boats, yachts, and other watercraft. These coatings create a barrier against saltwater corrosion while maintaining a polished appearance, even in the harshest marine environments.

- Construction: Durability Beyond Architecture Electrostatic spray coatings contribute to the longevity of buildings, bridges, and towers. By providing weather resistance and preventing corrosion, these coatings ensure that the structural integrity and aesthetic appeal of construction projects endure over time.

- Electrical Equipment: Enhancing Safety and Reliability Electrical equipment demands precision and safety. Electrostatic coatings offer insulation and protection against electrical faults for devices such as transformers, switchgear, and high-voltage equipment, ensuring reliable performance.

- Sporting Goods: Performance Meets Resilience Sporting goods like bicycles and exercise equipment undergo rigorous usage. Electrostatic spray coatings protect against wear, ensuring that these items not only perform well but also maintain their appearance over time.

- Retail and Signage: Captivating Visuals, Enduring Impressions In the retail sector, electrostatic coatings provide store fixtures and signage with vibrant, long-lasting colors. These coatings contribute to captivating visual displays that withstand the test of time and foot traffic.

- Food & Beverage Industry: Hygienic and Reliable Food processing and packaging equipment require coatings that uphold hygiene standards. Electrostatic techniques create a protective layer on surfaces, preventing corrosion from food substances and ensuring the reliability of equipment.

- Small Parts and Components: Precision in Detail Even small components like gears and bolts benefit from electrostatic coatings. These coatings ensure uniform coverage, enhancing the functionality and longevity of intricate parts.

- Bicycles and Computer Housing: Protection for Performance Bicycle frames and computer housings undergo constant exposure. Electrostatic coatings shield these items from environmental factors, maintaining their performance and appearance.

- Wooden Furniture and Stationeries: Preserving Elegance[dt_gap height=”10″ /] Electrostatic coatings add a protective layer to wooden furniture and stationeries, preventing scratches and wear while preserving their natural elegance.

- Hardware and Lockers: Enduring Functionality Hardware items and metal lockers are coated with precision to prevent rust and maintain smooth functionality, ensuring their longevity.

- Wind Power: Harnessing Sustainability with Coating Excellence In the realm of renewable energy, wind turbines stand tall as symbols of sustainability. Electrostatic spray coatings lend their expertise to these structures, safeguarding them against the forces of nature. By applying a durable and uniform layer, these coatings shield wind turbine components from corrosive elements, ensuring their efficiency and longevity in generating clean energy.

- Glass Products: Clarity and Protection in Perfect Balance The world of glass products, from windows to glass bottles, thrives on clarity and aesthetic appeal. Electrostatic spray coatings offer a delicate balance between protection and visibility. They guard against scratches, weathering, and pollutants while allowing the true beauty of glass to shine through, maintaining the elegance of these products.

- Military Applications: Strengthening Defense with Endurance[dt_gap height=”10″ /] The military relies on equipment that can withstand the most challenging environments. Electrostatic spray coatings play a vital role in enhancing military equipment’s durability. From vehicles to weapons, these coatings form a resilient shield against corrosion and wear, ensuring that military assets remain operational and effective.

- Iron Railing and Metal Structures: Forging Protection with Elegance Iron railings, fences, and other metal structures blend security with aesthetics. Electrostatic spray coatings combine protection and elegance, guarding against rust and external factors while preserving the visual appeal of these architectural elements.

- Freezers and Commercial Refrigeration: Cold Storage, Lasting Shield Commercial freezers and refrigeration units are essential for storing perishable goods. Electrostatic spray coatings provide a lasting shield against the moisture and temperature fluctuations inherent to these environments. By preventing rust and deterioration, these coatings contribute to the reliability of these cooling systems.

- Files and Office Storage: Preserving Order and Functionality Metal file cabinets and storage units are the backbone of organized offices. Electrostatic spray coatings preserve their appearance and functionality by preventing rust and maintaining smooth operation, ensuring that documents and materials remain secure and accessible.

- Musical Instruments: Notes of Protection for Timeless Melodies Musical instruments are not just tools; they are vessels of artistic expression. Electrostatic spray coatings contribute to their longevity, shielding them from external wear and tear without compromising their sound quality and aesthetic charm.

- Environmental Equipment: Purifying Air, Preserving Quality Environmental equipment such as air purifiers and water filtration systems play a crucial role in maintaining clean surroundings. Electrostatic spray coatings help these systems remain effective by preventing corrosion and ensuring the purification process remains uncompromised.

Collaborative Customization

OTSON Technologies Corp collaborates closely with clients to tailor electrostatic painting systems that align with specific needs. The experienced team of engineers and technicians ensures that each system integrates seamlessly into existing operations, maximizing efficiency and results.

Installation and Commissioning Services

A successful transition to electrostatic painting requires meticulous installation and commissioning. OTSON’s dedicated support ensures that systems are set up correctly and optimized for peak performance.

Training and After-Sales Support

Empowering clients to make the most of their investment, OTSON provides comprehensive training for operators and maintenance personnel. Additionally, robust after-sales support guarantees ongoing assistance and efficient resolution of any issues.

Q1.How durable is electrostatic paint?

A . Electrostatically applied coatings exhibit remarkable durability, often outlasting traditional paint methods due to their strong adhesion and uniform coverage.

Q2.Can existing paint shop systems be upgraded?

A .Yes, many existing paint shop systems can be upgraded to incorporate electrostatic painting technology. A consultation with OTSON’s experts can determine the feasibility of such upgrades.

Q3.What safety measures are needed?

A. Electrostatic painting involves electrical charges. Proper grounding, protective gear, and adherence to safety protocols are essential to prevent accidents.

Q4.Is electrostatic painting environmentally friendly?

A.Absolutely. The reduction in overspray, use of eco-friendly coatings, and energy-saving technologies collectively position electrostatic painting as an environmentally conscious choice.

Q5.How does electrostatic painting compare to traditional methods?

A.Electrostatic painting surpasses traditional methods in terms of efficiency, paint adhesion, and environmental impact. The precision and targeted application make it a superior choice for various industries.

Electrostatic painting has revolutionized the world of paint shop systems, ushering in a new era of efficiency, precision, and sustainability. From its innovative process to its multifaceted benefits, this technology continues to shape industries that rely on immaculate finishes and durable coatings. With OTSON Technologies Corp leading the charge in pioneering these advancements, businesses can access a brighter, greener, and more efficient future.

FAQs

- How can I learn more about OTSON Technologies Corp’s electrostatic painting solutions? To explore more about OTSON’s innovative paint shop technologies, visit https://www.otson.com.

- Can electrostatic painting be applied to large-scale manufacturing? Absolutely, electrostatic painting is scalable and adaptable to both small and large-scale manufacturing processes.

- Are there limitations to the types of materials that can be painted using electrostatic methods? Electrostatic painting can be applied to a wide range of materials, including metals, plastics, and wood.

- What industries beyond automotive, aerospace, and woodworking can benefit from electrostatic painting? Industries such as electronics, appliances, and even medical devices can benefit from the precision and efficiency of electrostatic painting.

- Are there ongoing maintenance requirements for electrostatic painting systems? Regular maintenance is essential to ensure optimal system performance. OTSON provides comprehensive after-sales support to assist with maintenance needs.