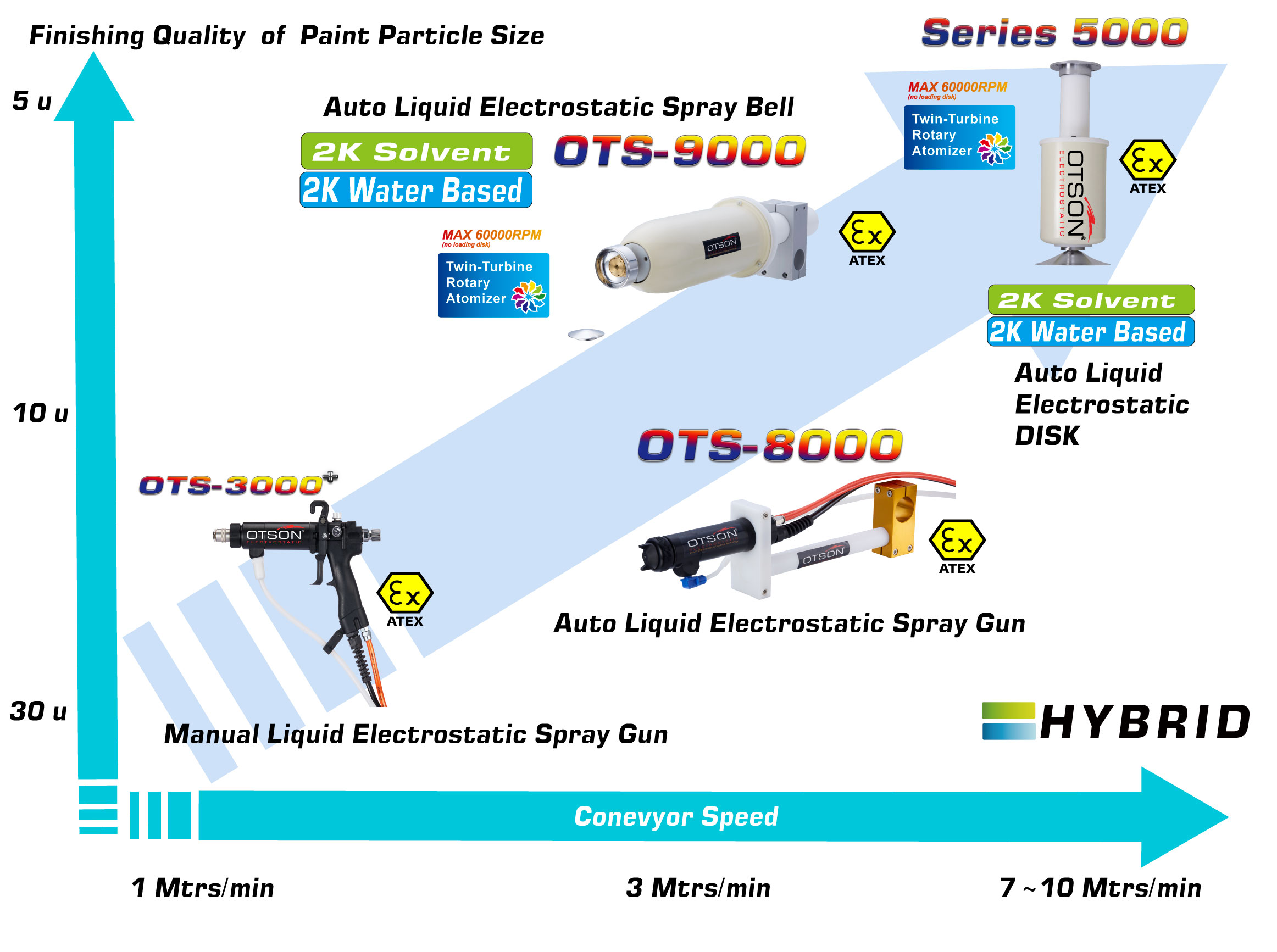

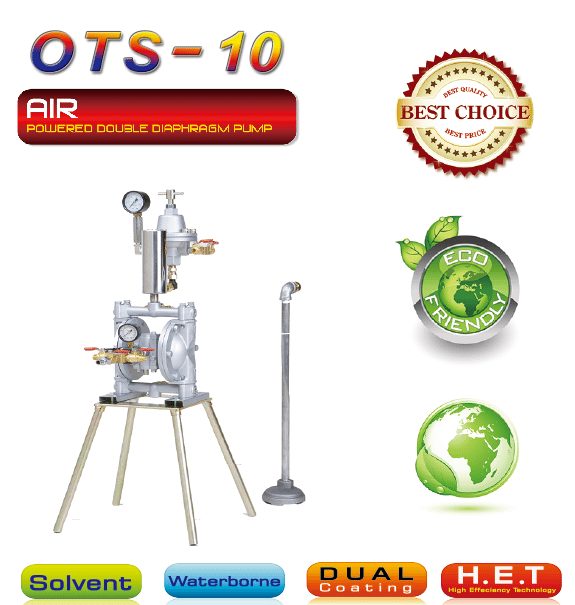

In the wooden industry, liquid electrostatic spray technology is commonly used to apply coatings such as paint, lacquers, and other finishing coatings to wooden products such as furniture, flooring, and other wooden structures. The process involves atomizing the liquid into droplets and then giving them an electrostatic charge. The charged droplets are then attracted to the grounded wooden items, ensuring an even and efficient coating.

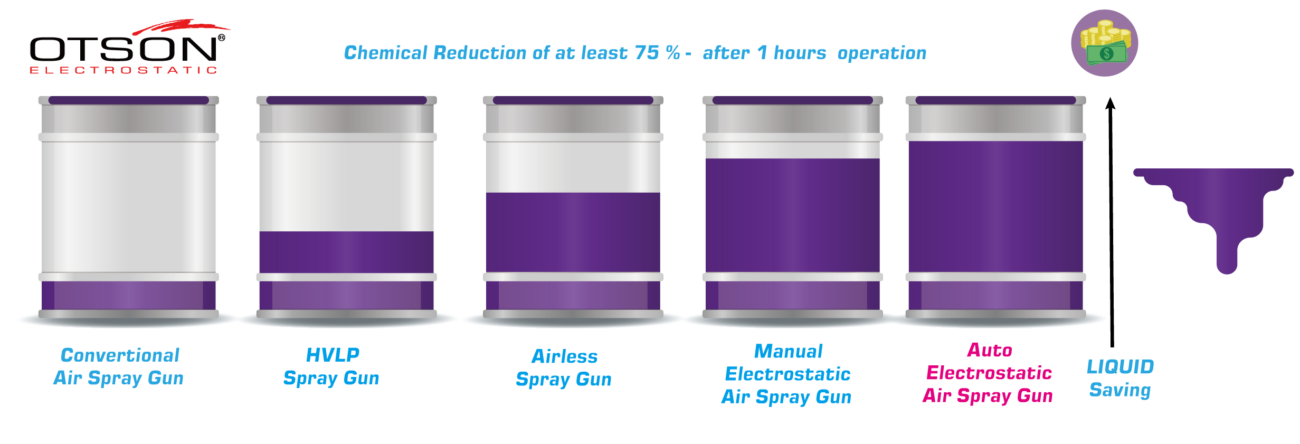

One of the main advantages of using liquid electrostatic spray in the wooden industry is the increased coating savings. The electrostatic charge causes the coating droplets to be attracted to the wooden items, resulting in less overspray and a more efficient use of the coating. This can lead to cost savings for the customer, as less coating is needed to achieve the same coverage as traditional spray methods.

Another advantage is the improved transfer efficiency. The electrostatic charge causes the coating droplets to be attracted to the wooden items, resulting in a higher percentage of the coating being deposited on the wooden items and less being wasted as overspray. This leads to a more consistent and even coating, with fewer drips and runs.

In addition, liquid electrostatic spray technology allows for the application of a wide range of coatings, including paint, lacquers, and other finishing coatings that are essential in the wooden industry to enhance the appearance and durability of the wooden products.

Furthermore, liquid electrostatic spray can be used to apply multiple layers of coating, which is important for wooden products such as furniture and flooring where multiple layers of coating are required to provide protection and durability against the elements, wear and tear, and also to maintain the hygiene and cleanliness of the wooden products.

Overall, liquid electrostatic spray technology is a cost-effective and efficient method of applying coatings to wooden products such as furniture and flooring in the wooden industry. It offers advantages such as increased coating savings, improved transfer efficiency, and versatility in application. It is also able to apply multiple layers of coating, providing protection and durability to the wooden products, enhancing the appearance of the wooden products and maintaining hygiene and cleanliness of the wooden products.