Liquid Electrostatic Spray Coating Technologies: Transforming the Small Parts Industry

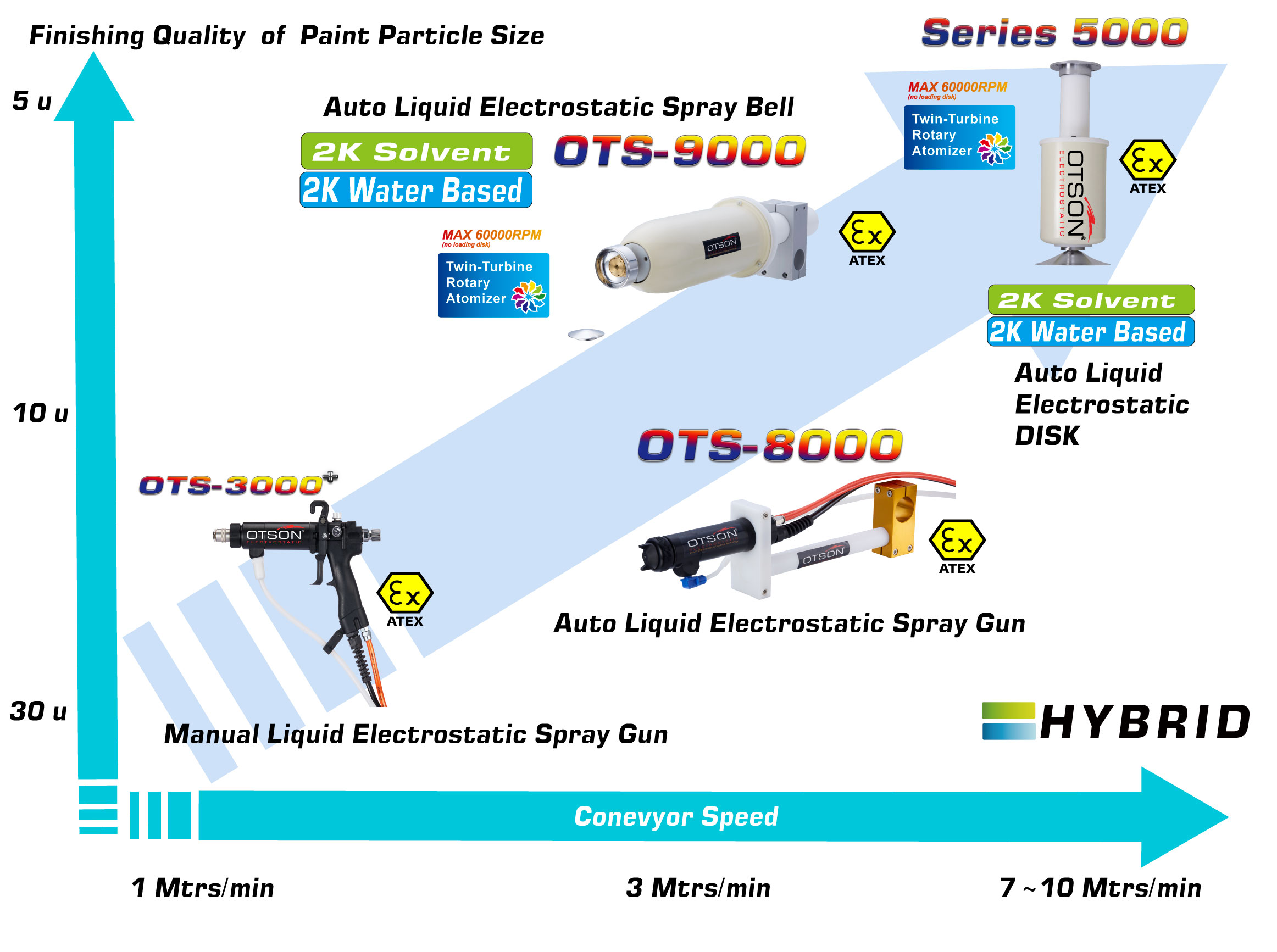

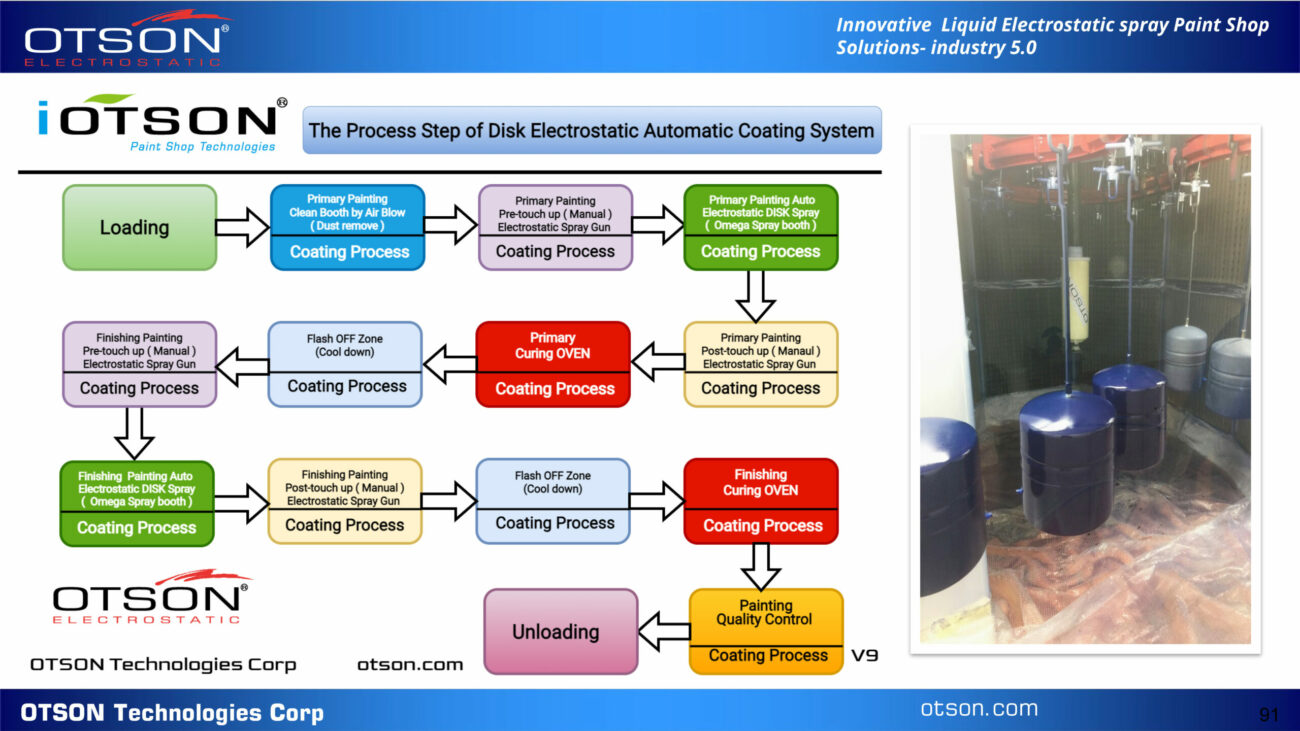

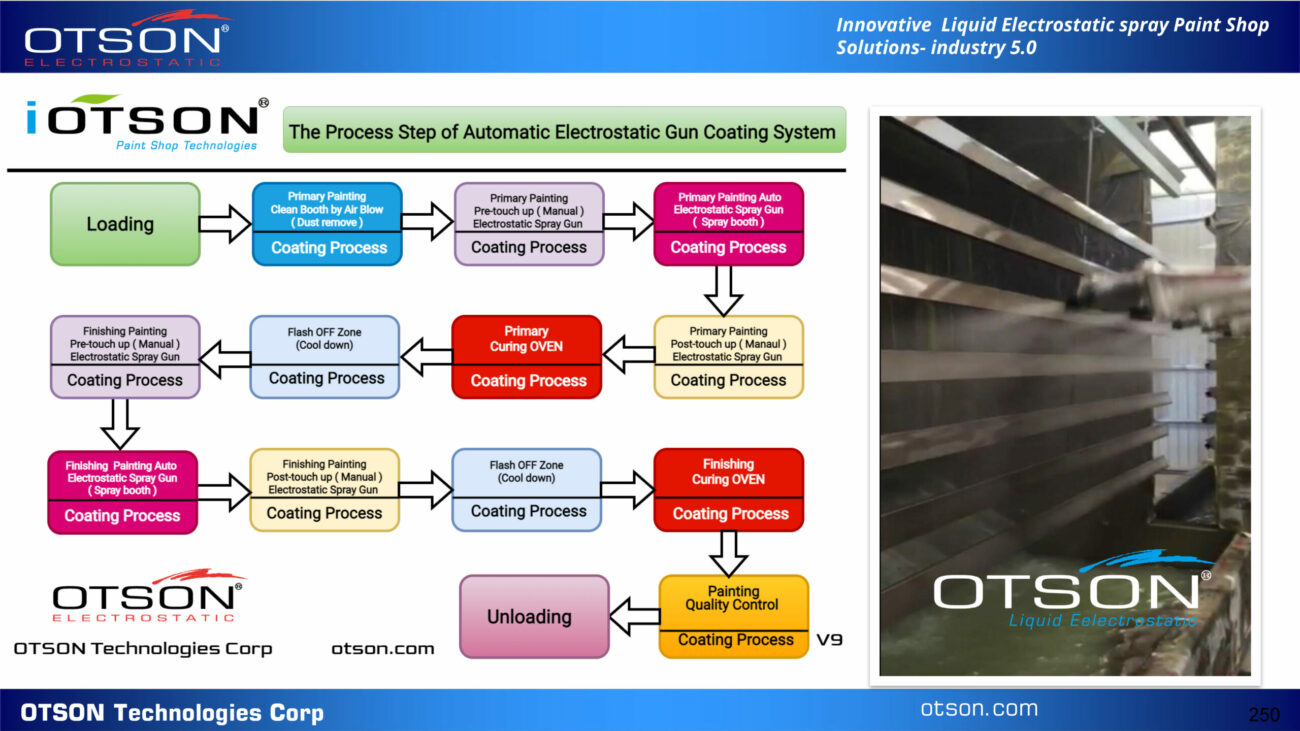

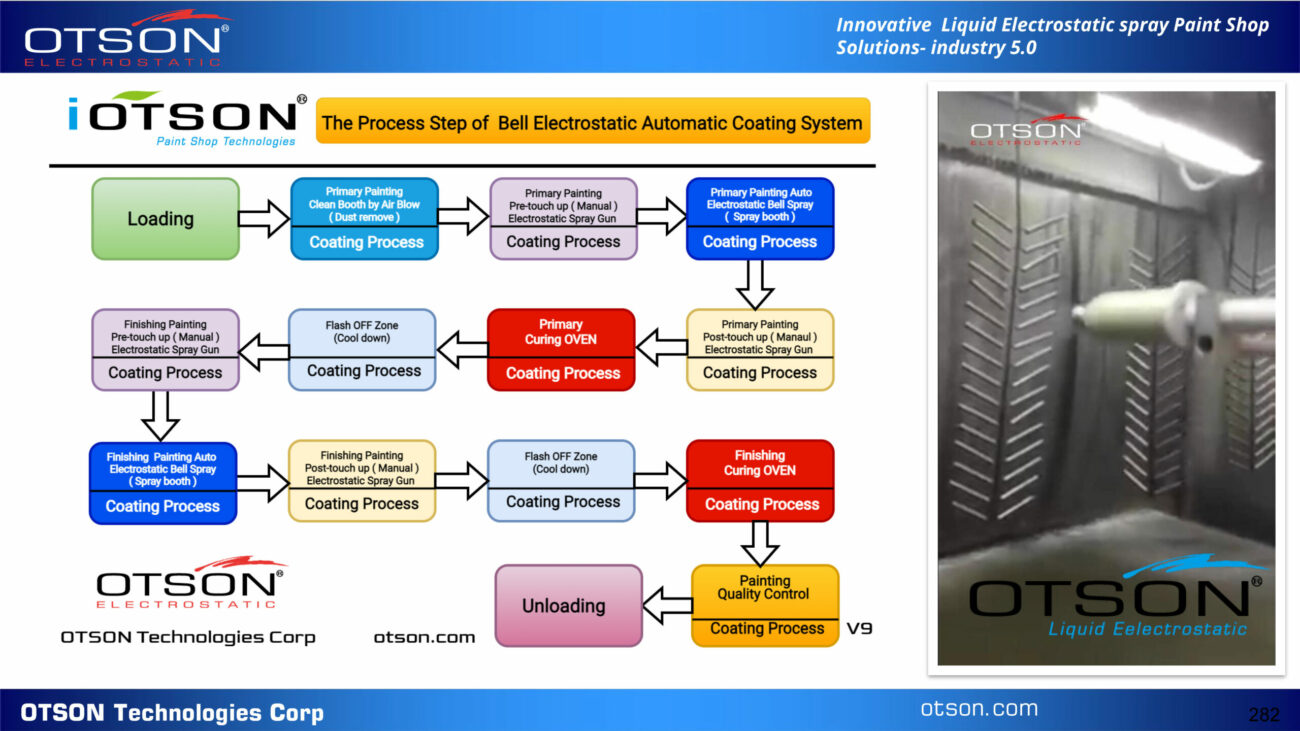

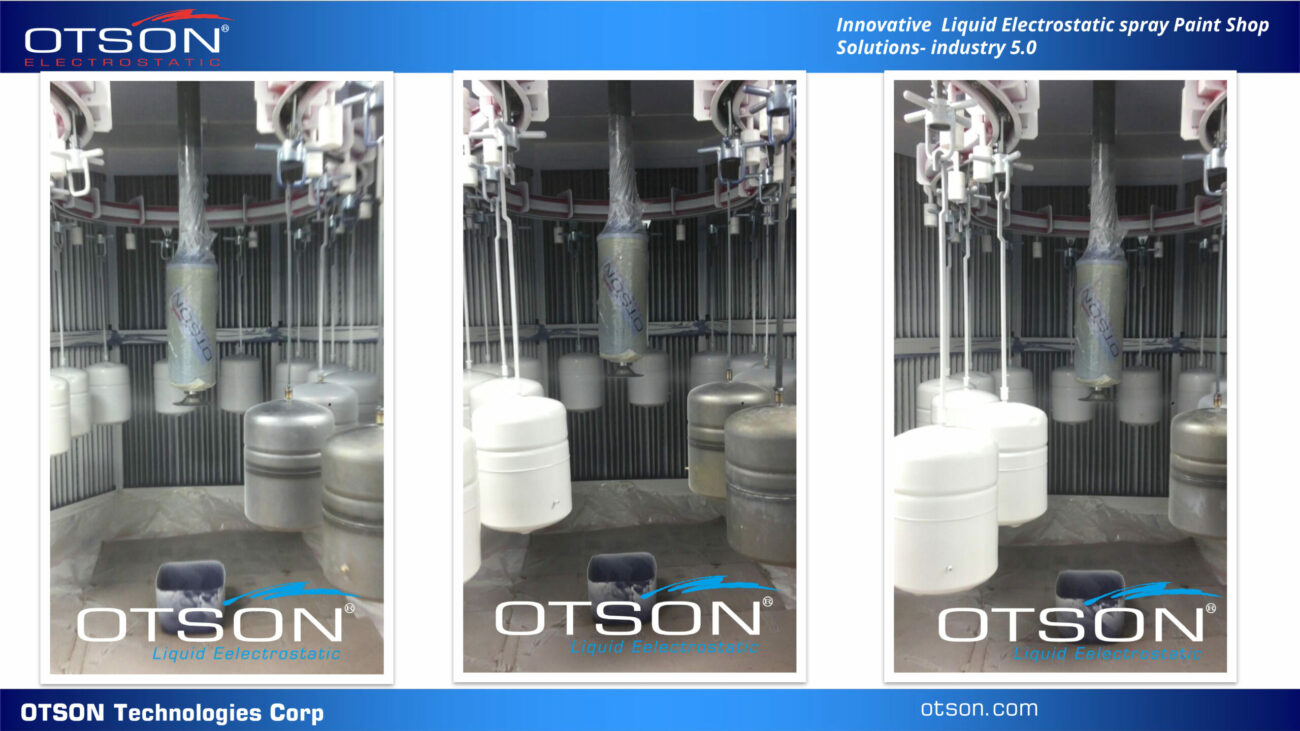

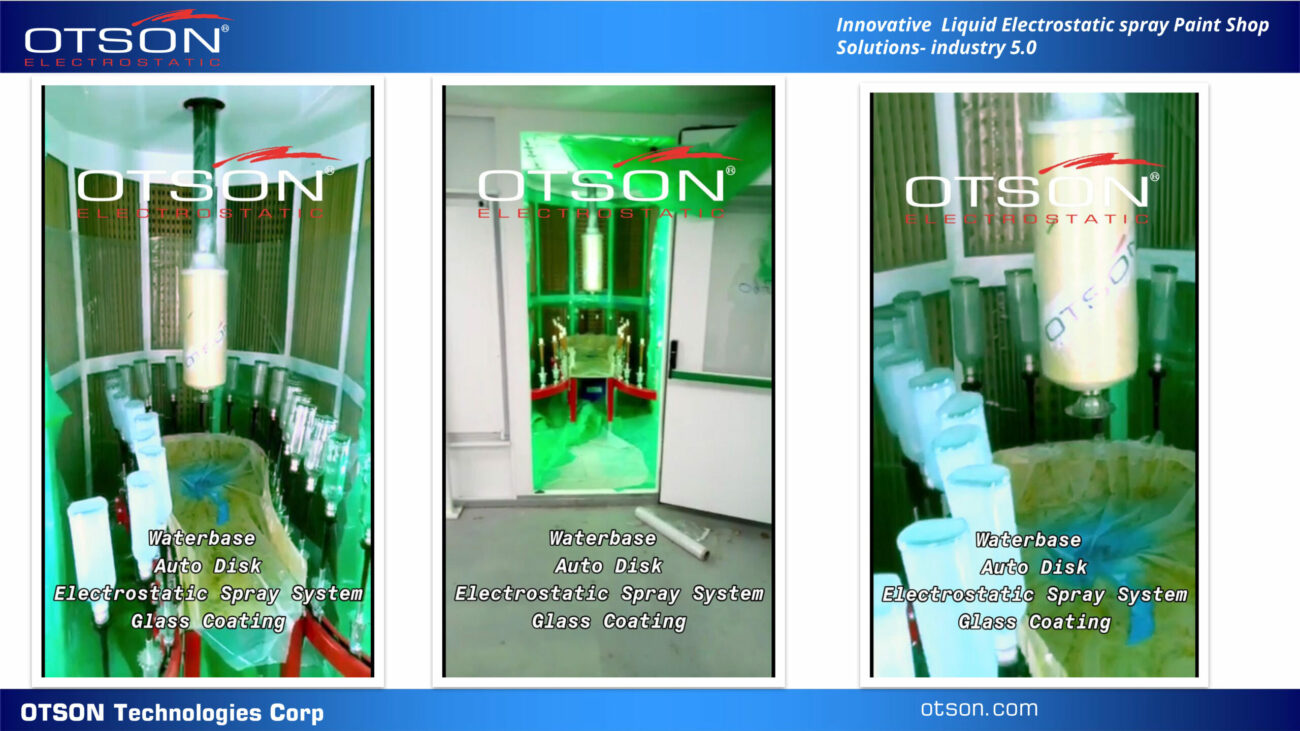

Liquid electrostatic spray coating technologies have revolutionized the application of liquid coatings on small parts across various industries. By utilizing an electrostatic charge, this process atomizes the liquid into fine droplets, which are then charged electrostatically. These charged droplets are attracted to the grounded small parts, ensuring a uniform and efficient coating. This innovative approach has become a crucial solution for a multitude of industries dealing with small components, enhancing their manufacturing processes and overall product quality.

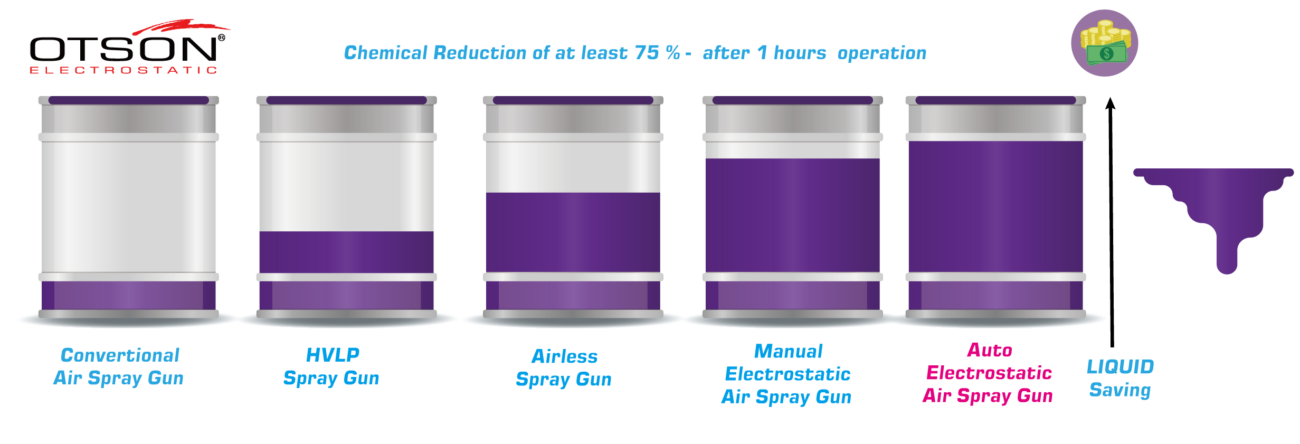

One of the primary advantages of liquid electrostatic spray coating technologies for small parts is the significant paint and coating savings. The electrostatic charge causes the coating droplets to be drawn to the parts, minimizing overspray and enabling more efficient use of the coating material. As a result, less coating is required to achieve the same coverage as traditional spray methods, leading to cost savings and reduced material waste.

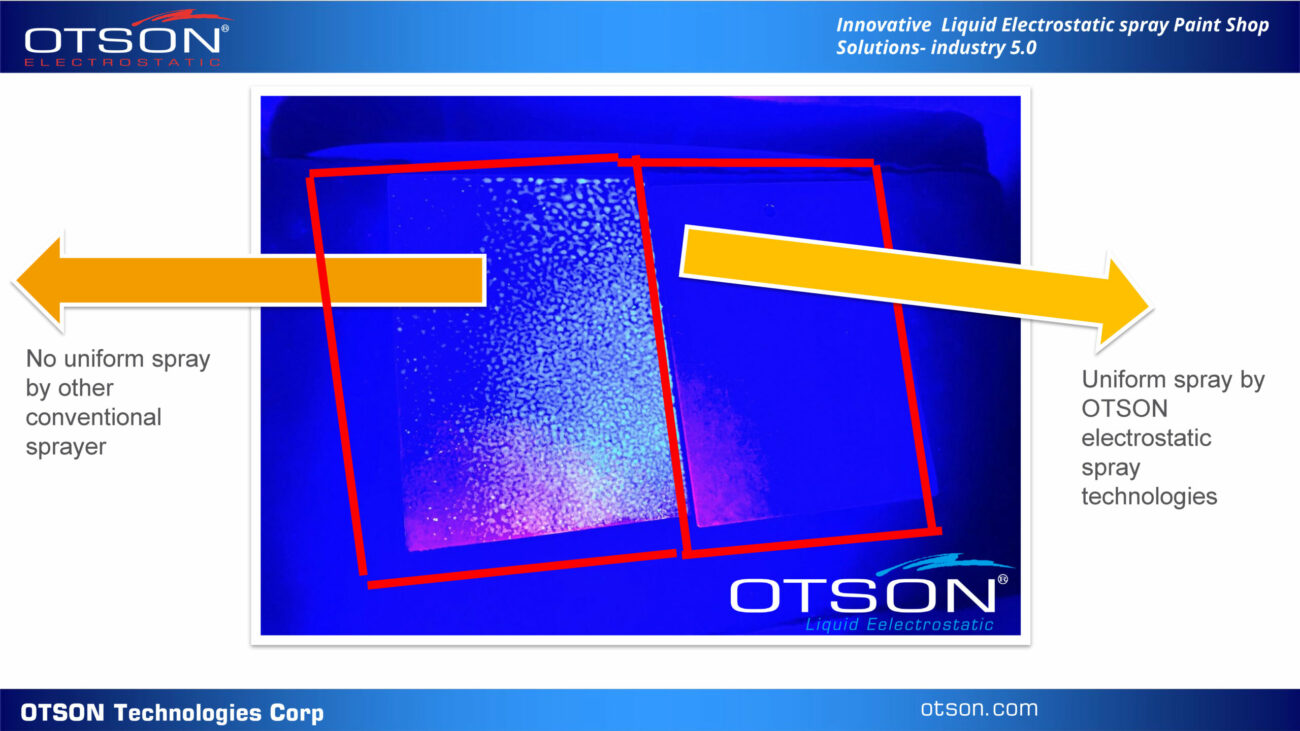

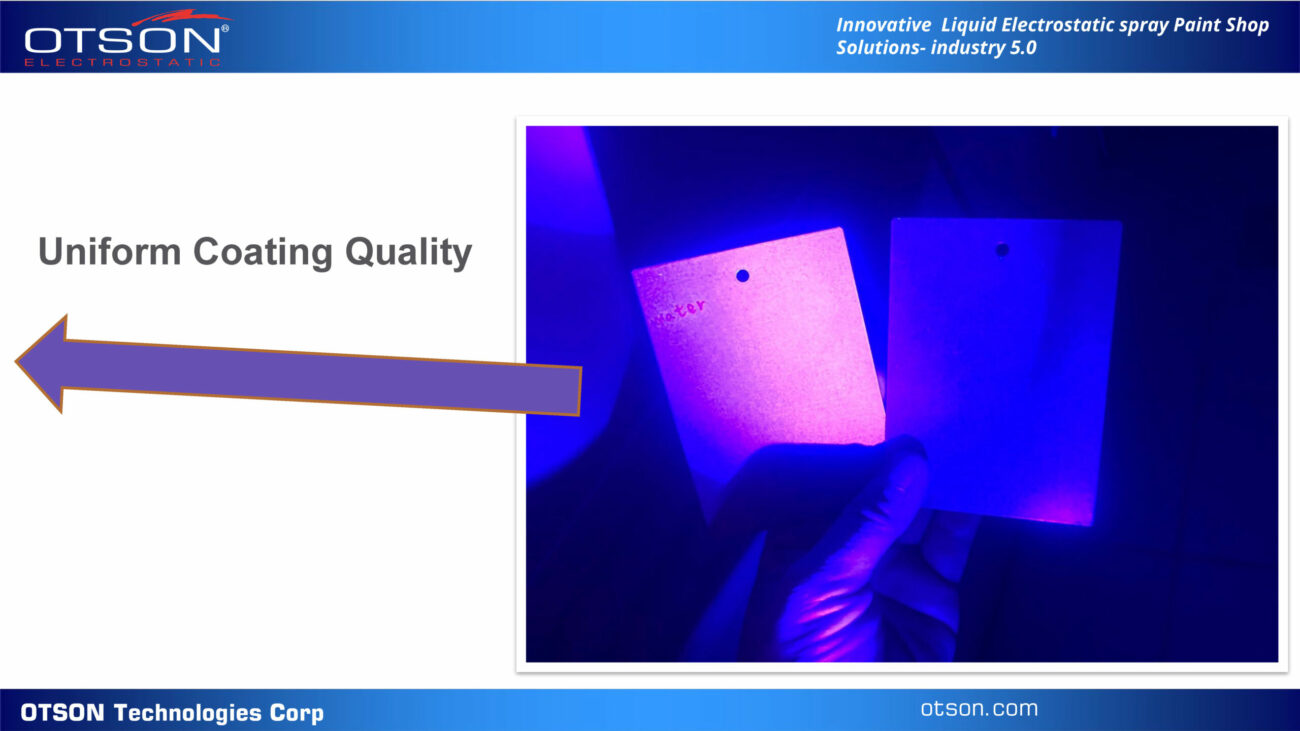

Furthermore, liquid electrostatic spray coating technologies offer improved transfer efficiency for small parts. The electrostatic charge ensures that a higher percentage of the coating adheres to the parts, with less being lost as overspray. This results in a more consistent and even coating, minimizing drips, runs, and other imperfections that may impact the final product’s quality.

In addition, the reduction of overspray associated with liquid electrostatic spray coating technologies contributes to better air quality and a more streamlined cleanup process. Conventional spray methods often generate substantial overspray, which can be harmful to the environment and necessitate time-consuming cleanup. Electrostatic spray technology, on the other hand, mitigates overspray and simplifies the cleanup process, increasing overall efficiency.

Lastly, liquid electrostatic spray coating technologies can accommodate a wide variety of coatings, including paints, primers, clearcoats, and more. This versatility makes them suitable for numerous applications across industries that rely on small parts, such as electronics, medical devices, and precision engineering.

In conclusion, liquid electrostatic spray coating technologies have transformed the small parts industry by providing a highly efficient and cost-effective method for applying various coatings. With benefits such as increased material savings, enhanced transfer efficiency, reduced overspray, and improved air quality, these technologies have become indispensable for manufacturers seeking to optimize their processes and deliver high-quality products.