Plastic Industry: Liquid Electrostatic Spray Coating Technologies and Advanced Paint Shop Solutions by OTSON

The plastic industry is no stranger to the constant need for precision, efficiency, and sustainability in production processes. As demand for plastic components continues to grow across sectors such as automotive, electronics, consumer goods, and medical devices, innovative coating technologies have emerged to meet stringent quality and environmental standards. OTSON is at the forefront of these innovations, offering state-of-the-art liquid electrostatic spray coating technologies and advanced paint shop solutions. These technologies are designed to maximize transfer efficiency, minimize waste, and provide superior coatings for plastic parts.

Introduction to Liquid Electrostatic Spray Coating

Liquid electrostatic spray coating has revolutionized the painting process in the plastic industry. This technique leverages the principles of electrostatic charge to ensure that the paint particles adhere perfectly to the surface of plastic components. Not only does this result in a high-quality finish, but it also significantly reduces overspray, making it an eco-friendly and cost-effective solution for manufacturers.

What is Liquid Electrostatic Spray Coating?

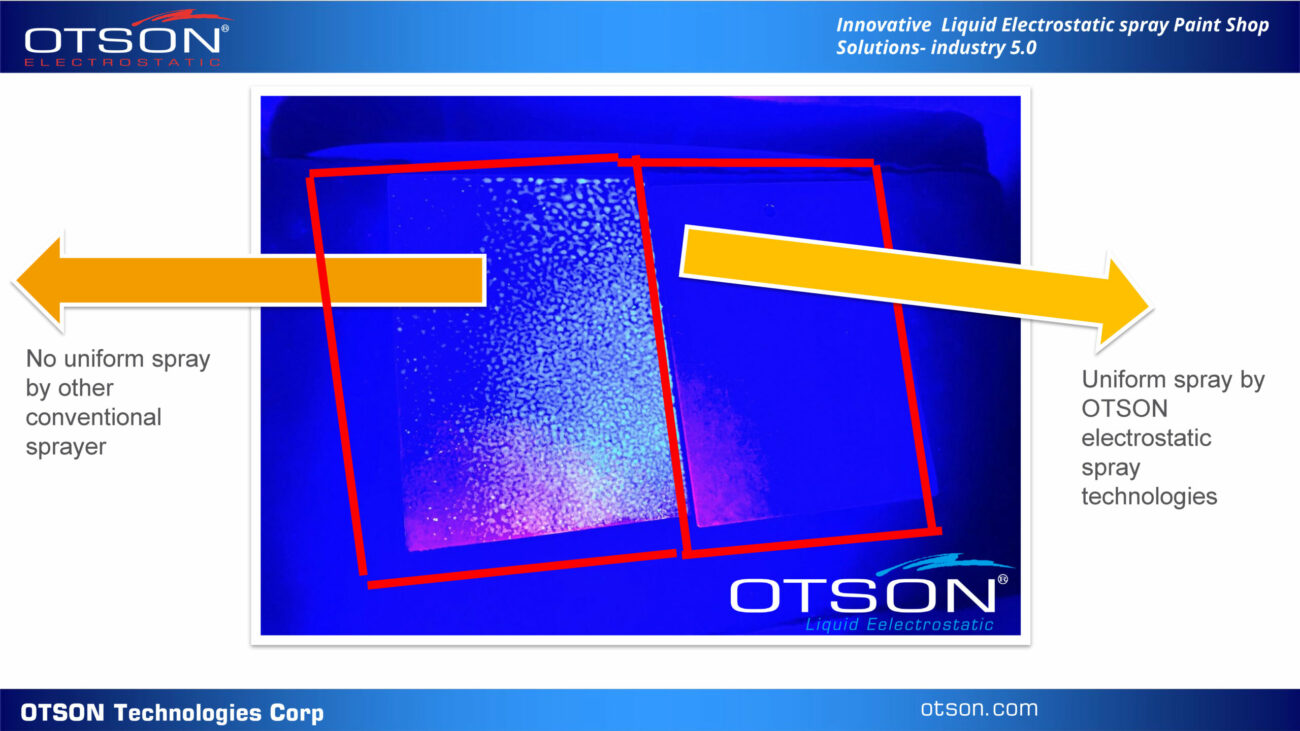

At its core, electrostatic spray coating involves charging paint particles and directing them towards a grounded surface, typically plastic components. Since the plastic surface is oppositely charged, the paint particles are naturally drawn to it, resulting in uniform coverage. This precise targeting reduces waste and ensures that even the most intricate surfaces and geometries receive consistent coatings.

OTSON’s liquid electrostatic spray systems utilize cutting-edge atomization technology and automation to enhance efficiency and precision in the coating process, whether for small-batch productions or high-volume operations.

Key Benefits of Liquid Electrostatic Coating in Plastic Manufacturing

The benefits of using electrostatic spray coating in the plastic industry are manifold. By embracing this technology, manufacturers can not only enhance the visual and physical properties of their products but also achieve greater operational efficiencies.

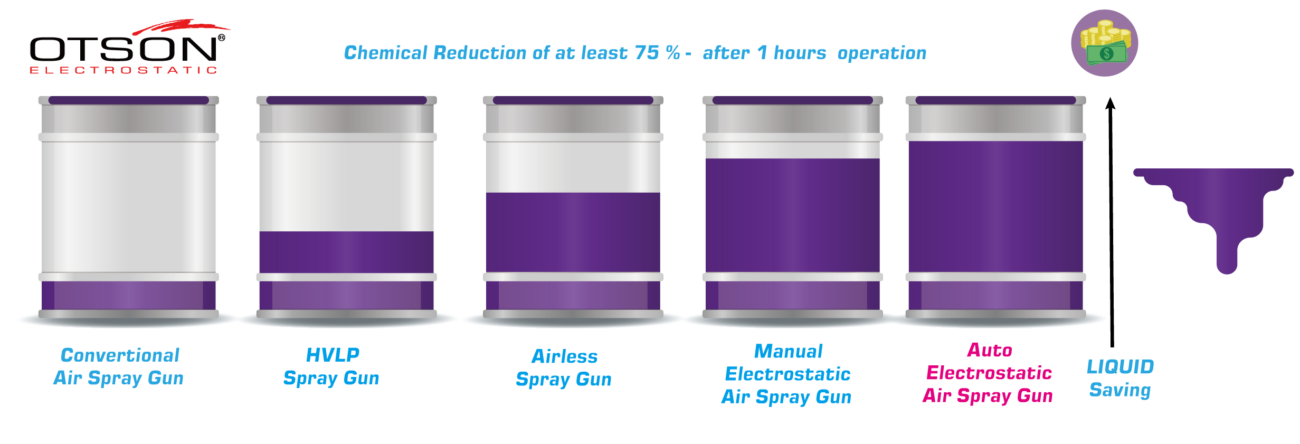

High Transfer Efficiency

One of the most notable advantages of electrostatic spray coating is its exceptionally high transfer efficiency—often reaching rates as high as 95%. This means that nearly all the paint is deposited onto the plastic surface, minimizing waste. Traditional spray methods, by contrast, often result in significant paint overspray and loss, leading to higher material costs.

Cost-Efficient Production

For plastic manufacturers, OTSON’s technology translates into reduced labor and material costs. High transfer efficiency reduces the amount of paint required per unit, while automation ensures consistent results, reducing the need for costly rework. Additionally, the rapid throughput of automated systems allows businesses to meet demand without sacrificing quality.

Eco-Friendly Solutions

Sustainability has become a critical consideration for manufacturers. Liquid electrostatic spray coating helps companies reduce their environmental footprint by minimizing volatile organic compound (VOC) emissions and lowering paint waste. This eco-friendly approach aligns with global efforts to reduce industrial emissions and comply with stringent environmental regulations.

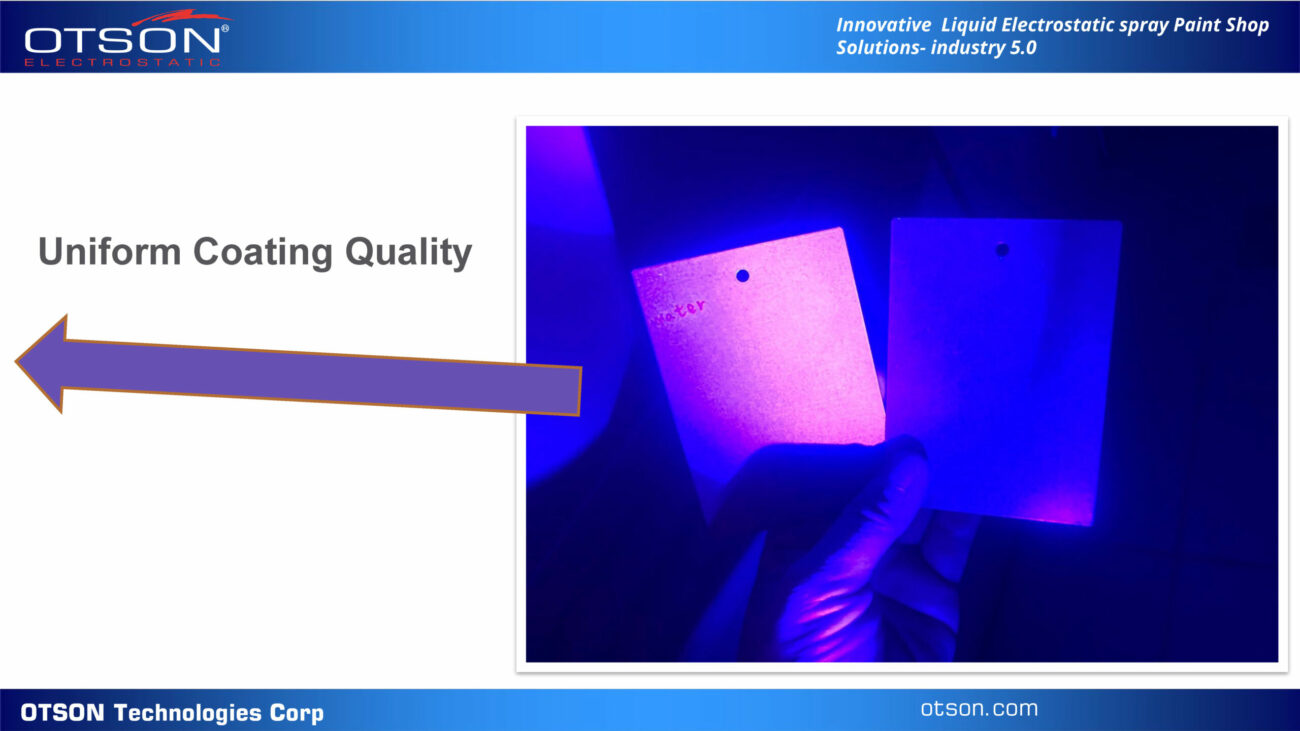

Precision Coating

The electrostatic charge ensures that paint particles are evenly distributed across the entire surface of the plastic component. Whether dealing with complex geometries or irregular surfaces, OTSON’s technology guarantees a smooth, high-quality finish. The precision of this technology helps manufacturers achieve uniform coatings, enhancing both the durability and aesthetic appeal of plastic products.

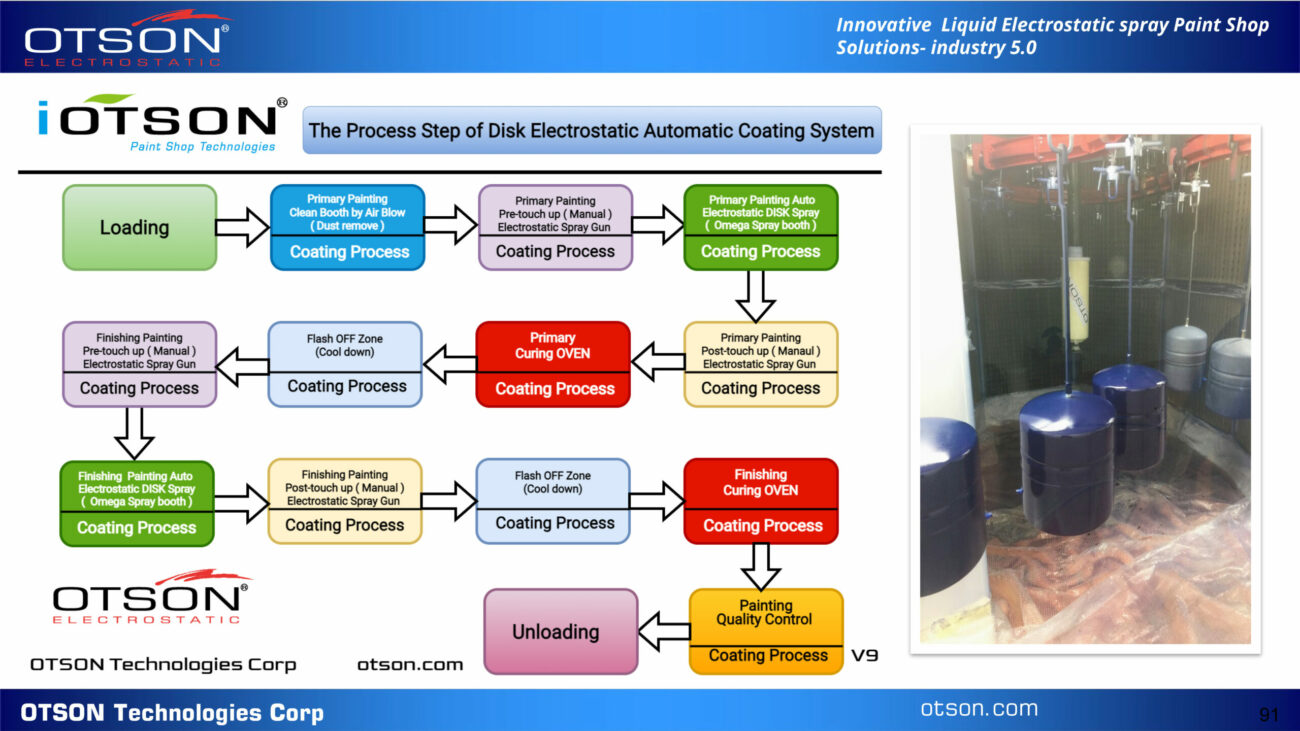

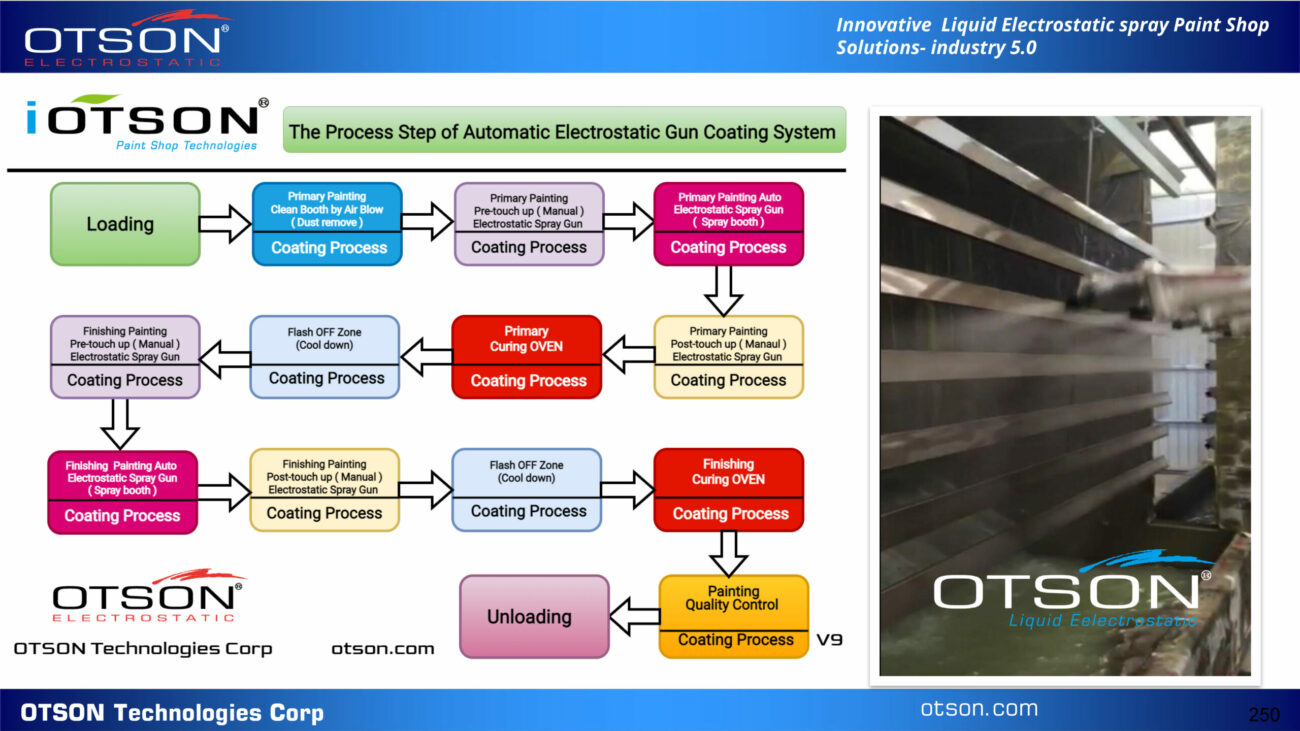

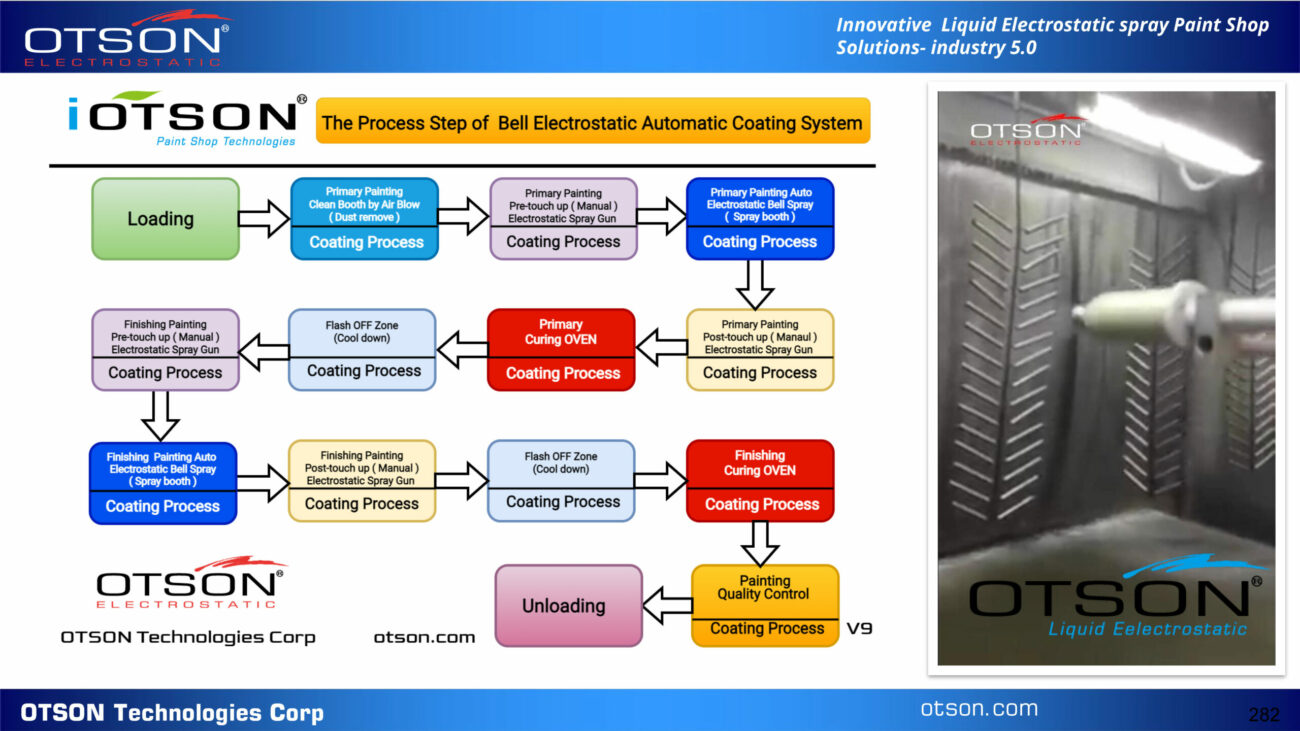

OTSON’s Advanced Paint Shop Solutions for Plastic Components

At OTSON, we believe that the future of the plastic industry lies in advanced, customizable solutions that can adapt to the needs of modern manufacturers. Our paint shop solutions integrate seamlessly into existing production lines, offering enhancements in efficiency, safety, and product quality.

Dual Coating Technology

One of the standout features of our systems is their ability to handle both solvent-based and waterborne paints. This dual compatibility offers unmatched flexibility, allowing manufacturers to adapt to different coating requirements without investing in separate systems. Whether your business focuses on environmentally friendly water-based paints or relies on traditional solvent-based coatings, OTSON’s systems can accommodate your needs.

Automated Efficiency

Automation is key to maintaining consistent production quality and meeting the high-volume demands of the plastic industry. Our automated spray systems are designed to optimize production rates, minimize human error, and ensure uniform coatings on every part. By reducing manual intervention, OTSON’s automated solutions help manufacturers cut labor costs and achieve higher throughput.

Real-Time Monitoring with IoT

Our paint shop solutions are equipped with IoT-enabled sensors that provide real-time data analysis and predictive maintenance alerts. This advanced monitoring system ensures that any potential issues are identified before they lead to costly downtime, thus keeping production running smoothly and efficiently.

Innovative Electrostatic Coating Solutions for Plastic Manufacturing

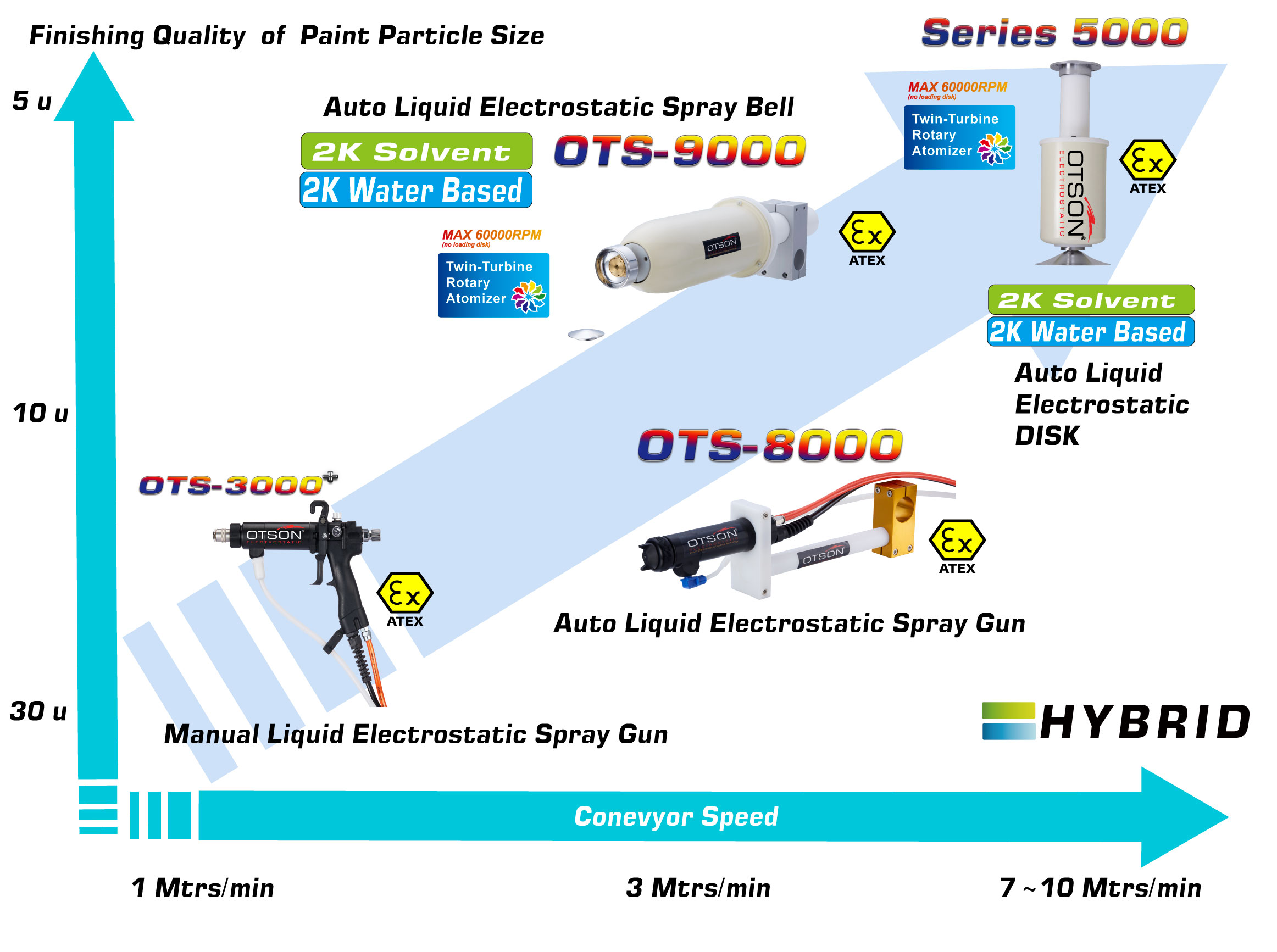

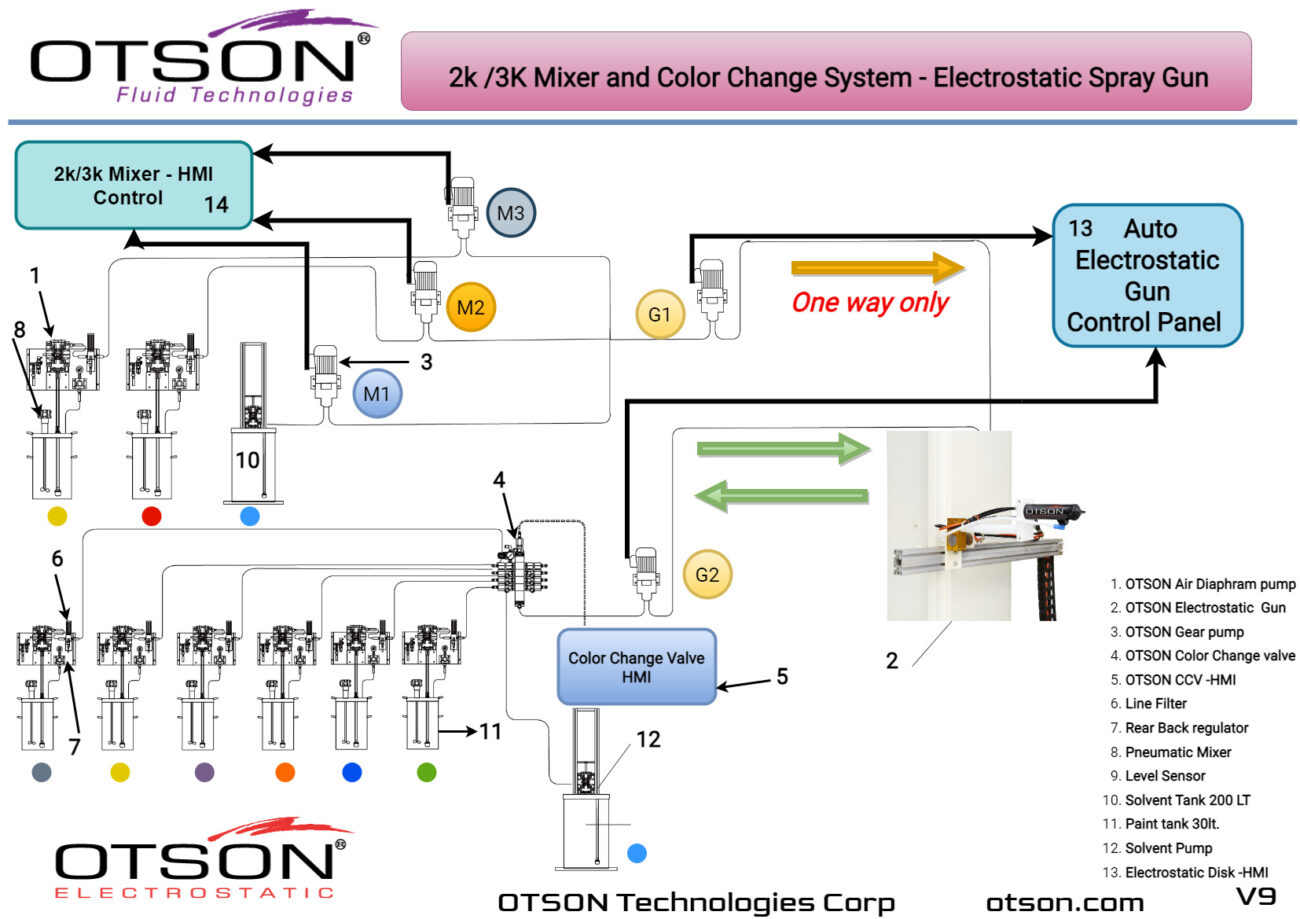

OTSON offers a comprehensive range of electrostatic spray coating systems, each tailored to meet the specific demands of plastic manufacturers. Below is an overview of some of our most popular models, each designed for different operational scales and requirements.

OTS-3000 Manual Liquid Electrostatic Spray Gun System

For manufacturers looking to maintain precise control over small to medium-sized production runs, the OTS-3000 manual spray system is an ideal solution. Its lightweight design and advanced atomization technology allow for fine control, ensuring a consistent, smooth finish with minimal overspray. The manual system is perfect for coating delicate plastic components with intricate details.

OTS-7800 Auto Electrostatic Spray Gun – Robot Arm

The OTS-7800 is a fully automated system that integrates seamlessly into robotic arms, making it perfect for large-scale manufacturing. Its precision coating technology ensures uniform finishes, even on complex plastic parts such as automotive trims and bumpers. For manufacturers aiming to increase their production capacity without sacrificing quality, this system is an ideal choice.

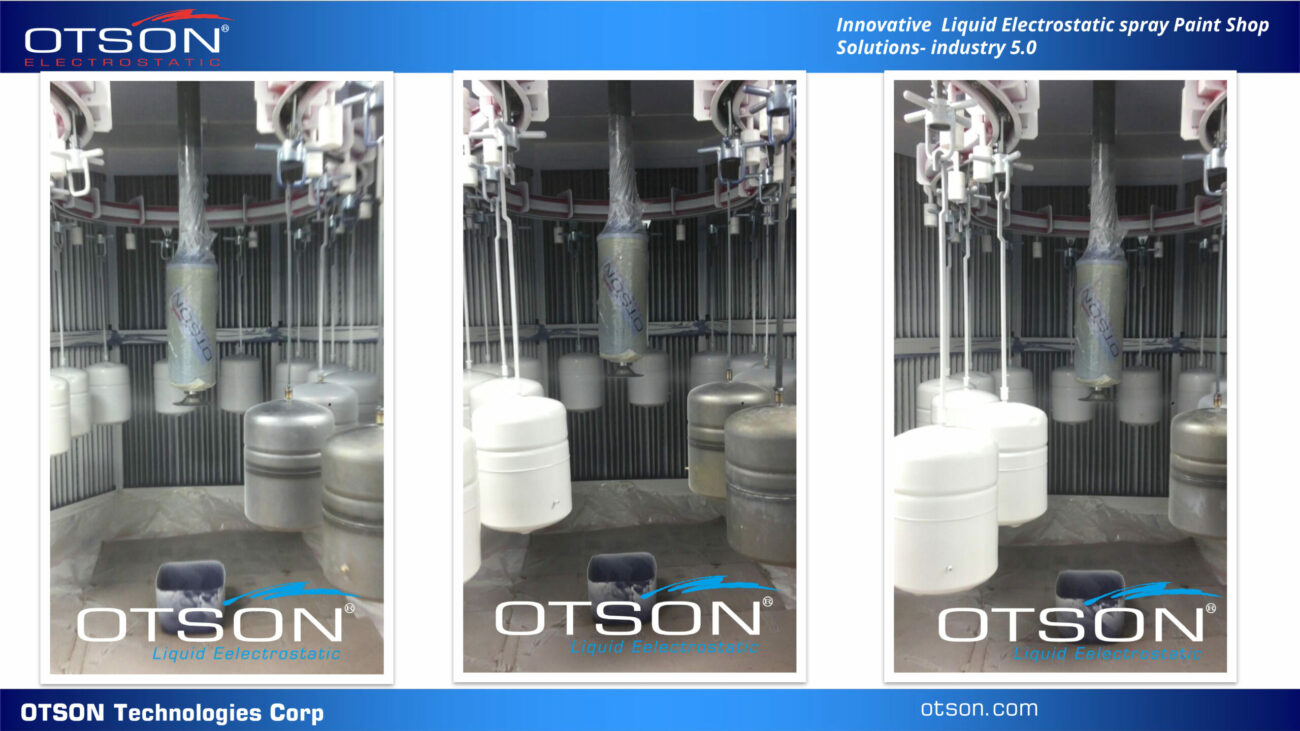

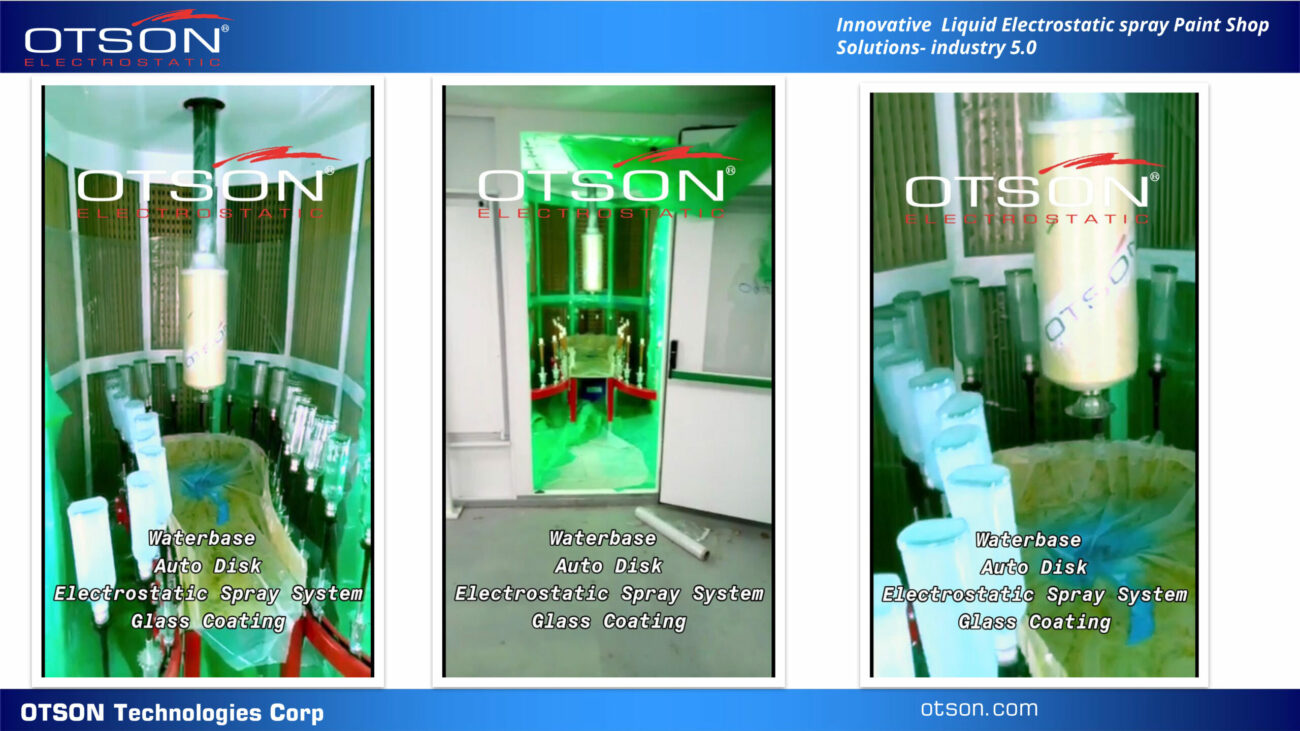

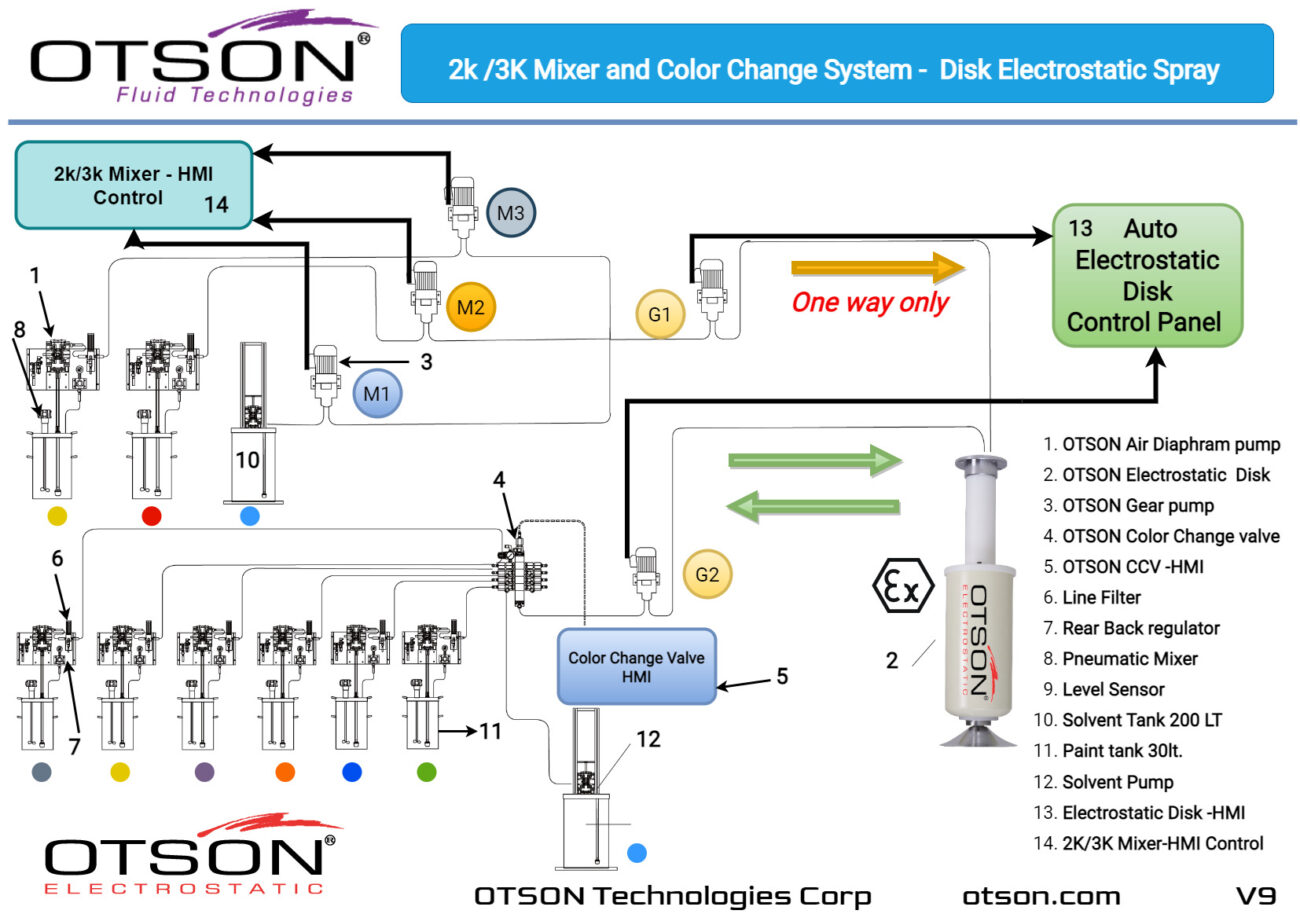

OTS-5000 Auto Electrostatic Spray Disk System

For high-volume production environments, the OTS-5000 offers unmatched efficiency. This system ensures uniform film thickness across all surfaces, minimizing paint waste. It’s particularly well-suited for industries where consistent coatings are critical, such as consumer electronics or medical devices.

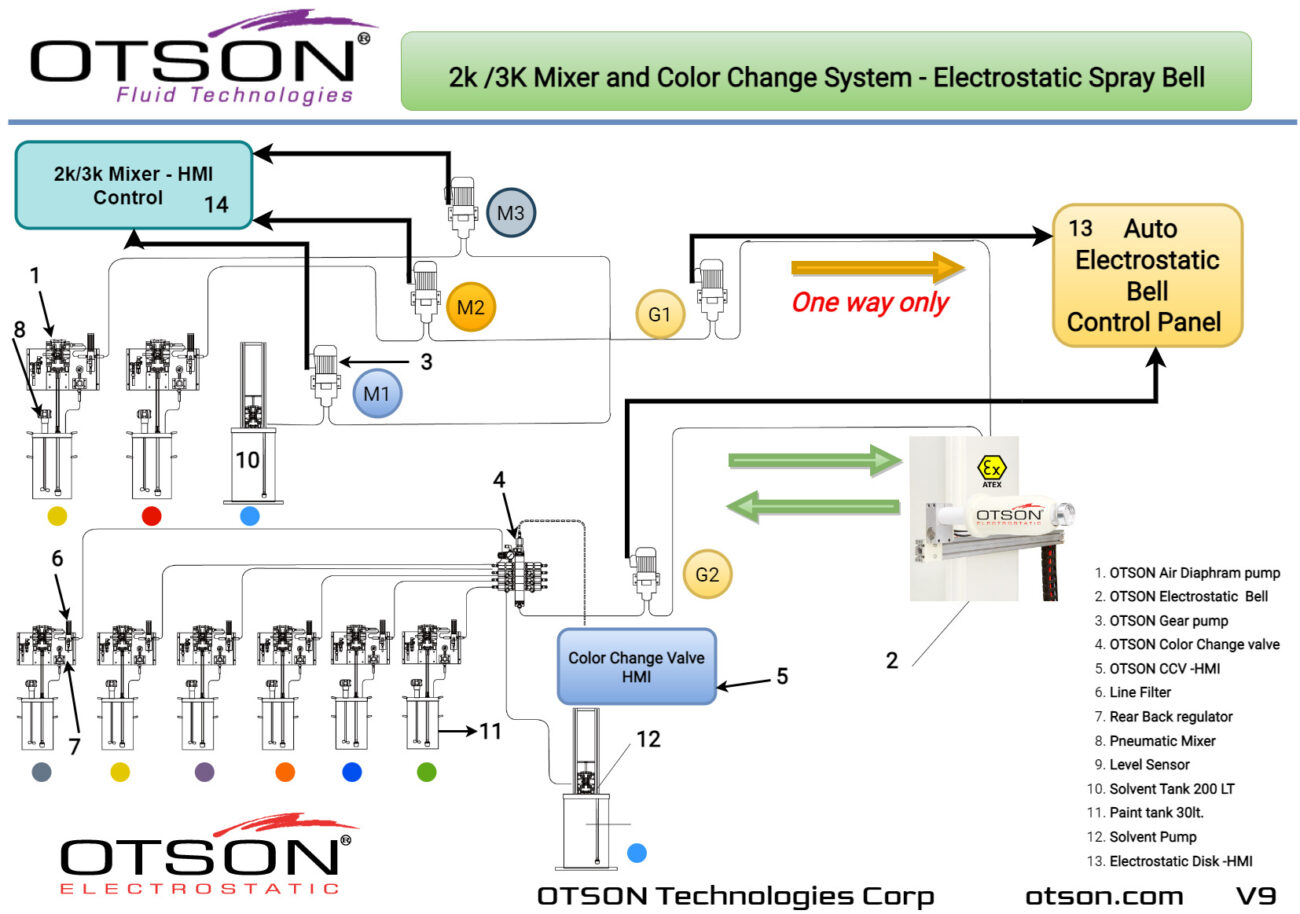

OTS-7900 and OTS-9000 Auto Electrostatic Spray Bell Systems

For businesses seeking to coat plastic components using both solvent-based and waterborne paints, the OTS-7900 and OTS-9000 systems provide the perfect solution. With high atomization capabilities and superior paint coverage, these systems are designed for high-speed, mass-production environments. The OTS-9000 is especially notable for its 95% transfer efficiency, making it one of the most environmentally friendly options on the market.

The Importance of Electrostatic Coating in the Plastic Industry

Plastic components often face challenging environmental conditions, from exposure to UV light to physical wear and tear. Electrostatic spray coatings provide an additional layer of protection, extending the life of plastic parts and enhancing their durability.

Enhanced Durability and Protection

By applying an electrostatic coating, manufacturers can significantly improve the resistance of plastic parts to environmental stressors. This is particularly important for products exposed to harsh conditions, such as automotive components or outdoor consumer goods. The coating acts as a protective barrier, guarding against UV degradation, moisture, and abrasion.

Superior Adhesion and Aesthetic Appeal

Electrostatic forces ensure that the paint adheres evenly across the surface, creating a uniform and smooth finish. This not only enhances the appearance of the product but also prevents common issues like peeling, flaking, or blistering, which can occur with inferior coating methods.

Sustainable and Cost-Effective Coating Solutions

In an era where sustainability is more than just a buzzword, OTSON is leading the way by offering advanced coating systems that prioritize both environmental responsibility and operational efficiency. Plastic manufacturers worldwide are increasingly recognizing the need to adopt technologies that not only enhance product quality but also reduce their carbon footprint.

Reduced VOC Emissions

A key environmental benefit of OTSON’s liquid electrostatic spray coating technology is the significant reduction in volatile organic compound (VOC) emissions. VOCs are harmful chemicals that contribute to air pollution and pose health risks to workers and surrounding communities. OTSON’s systems, by optimizing paint transfer and minimizing waste, ensure fewer VOCs are released during the coating process, making it easier for companies to comply with stringent environmental regulations.

Minimizing Waste Through Precision

The high transfer efficiency achieved by OTSON’s electrostatic systems plays a critical role in reducing material waste. By ensuring that more paint particles reach their intended target, manufacturers can drastically cut down on excess paint that would otherwise be lost to overspray. This not only reduces the cost of raw materials but also minimizes the environmental impact associated with disposing of unused paint and cleaning solvents.

Cost Savings Over Time

OTSON’s technology is designed for long-term cost savings. By using less paint and reducing rework, manufacturers can lower their operational costs significantly. Additionally, the durability of the coatings ensures that products last longer, reducing the need for frequent replacements or repairs, further saving money in the long run.

Industries Benefiting from OTSON’s Coating Technologies

OTSON’s liquid electrostatic spray coating systems are versatile, making them applicable across a wide range of industries that rely on high-quality, durable plastic components. Whether in mass production or niche manufacturing, OTSON’s advanced solutions ensure that products meet the highest standards of quality, efficiency, and sustainability.

Automotive Industry

The automotive industry is a key sector for OTSON’s electrostatic spray coating solutions. From bumpers and exterior trims to interior plastic components, OTSON’s systems deliver uniform, durable finishes that can withstand the rigors of everyday use. High transfer efficiency also ensures that automotive manufacturers can meet strict environmental standards while maintaining the aesthetics and longevity of their products.

Consumer Goods

In the consumer goods sector, plastic components are integral to the design and functionality of countless products, from household appliances to toys. OTSON’s electrostatic spray coatings not only enhance the appearance of these products but also increase their resistance to wear and tear. This makes consumer goods more durable, contributing to higher customer satisfaction and reducing product returns or replacements.

Electronics

Electronic devices rely heavily on plastic casings and components for protection and insulation. OTSON’s coating systems provide the precision and consistency needed to apply protective coatings that ensure long-lasting performance. In addition to improving the aesthetic appeal, these coatings protect sensitive electronic parts from external damage, such as scratches, dust, and moisture.

Medical Devices

In the medical device industry, quality and safety are paramount. Plastic components used in medical equipment must meet strict regulatory standards, and OTSON’s electrostatic coating technology ensures that these components receive durable, high-quality finishes. The precision offered by OTSON’s systems guarantees that coatings are applied evenly, minimizing any risks associated with coating defects that could compromise the integrity of the medical devices.

OTSON’s Commitment to Innovation

At OTSON, innovation is not just a goal—it’s a commitment. We are constantly pushing the boundaries of what is possible in electrostatic coating technology, integrating the latest advancements in Industry 4.0 and Industry 5.0 to create solutions that are not only efficient but also future-proof.

Integrating Industry 4.0 for Enhanced Performance

The future of manufacturing lies in the smart factory, and OTSON is already there. Our paint shop solutions are equipped with advanced automation and IoT-enabled systems that allow for real-time monitoring of the entire coating process. This gives manufacturers unparalleled insight into their operations, enabling them to adjust variables like paint flow and spray intensity in real time to optimize performance.

Predictive maintenance is another critical advantage offered by OTSON’s IoT-enabled systems. By continuously monitoring equipment performance, manufacturers can identify potential issues before they lead to costly downtime. This proactive approach minimizes disruptions to production, increases system uptime, and ensures consistent quality.

Tailor-Made Solutions for Every Client

OTSON understands that no two manufacturing environments are alike, which is why we offer customizable coating solutions that can be tailored to the specific needs of each client. Whether your focus is on small-batch production or high-volume manufacturing, OTSON has the expertise to design a system that fits your operational requirements and maximizes efficiency.

Future-Proofing with Industry 5.0

As the manufacturing sector evolves, Industry 5.0 brings a human-centric approach to automation. OTSON is leading the way by integrating human expertise with advanced robotic systems to create a symbiotic relationship between man and machine. Our goal is to empower operators to work more efficiently with smart systems that enhance, rather than replace, human oversight.

Frequently Asked Questions

What are the main benefits of using OTSON’s electrostatic spray coating systems in the plastic industry?

OTSON’s systems provide high transfer efficiency (up to 95%), reducing material waste and enhancing cost savings. They offer superior finishes, eco-friendly operations with reduced VOC emissions, and compatibility with both solvent-based and waterborne paints, making them versatile for various applications.

How does OTSON’s technology contribute to environmental sustainability?

By minimizing overspray and reducing VOC emissions, OTSON’s electrostatic spray systems help manufacturers meet stringent environmental regulations while lowering their carbon footprint. The reduced paint waste also means fewer raw materials are consumed, further supporting sustainability efforts.

What industries can benefit from OTSON’s coating technologies?

OTSON serves a variety of industries, including automotive, consumer goods, electronics, and medical devices. Any industry that relies on high-quality, durable plastic components can benefit from the precision and efficiency of OTSON’s electrostatic spray coating systems.

How does OTSON’s IoT-enabled system improve production efficiency?

OTSON’s IoT-enabled systems provide real-time monitoring and predictive maintenance, allowing manufacturers to detect potential issues early and optimize production processes. This results in reduced downtime, improved system reliability, and consistent coating quality.

Are OTSON’s systems customizable to specific manufacturing needs?

Yes, OTSON offers tailor-made solutions designed to meet the unique operational requirements of each client. Whether you need systems for small-batch production or large-scale manufacturing, OTSON can create a solution that maximizes efficiency and quality.

What is the difference between OTSON’s OTS-3000 manual system and the OTS-9000 automated system?

The OTS-3000 is a manual system ideal for small to medium-sized productions that require precise control, whereas the OTS-9000 is a fully automated system designed for high-volume production environments. The OTS-9000 also boasts a higher transfer efficiency (up to 95%), making it a more eco-friendly option for large-scale operations.

Conclusion: Leading the Future of Plastic Coating Technologies

As the demands on plastic manufacturers continue to grow, OTSON’s liquid electrostatic spray coating technologies and advanced paint shop solutions offer a path forward. By combining precision, efficiency, and sustainability, OTSON provides manufacturers with the tools they need to stay competitive in a rapidly evolving market. From high transfer efficiency and environmental compliance to innovative automation and IoT-enabled systems, OTSON is committed to delivering solutions that meet the challenges of today while preparing for the future.