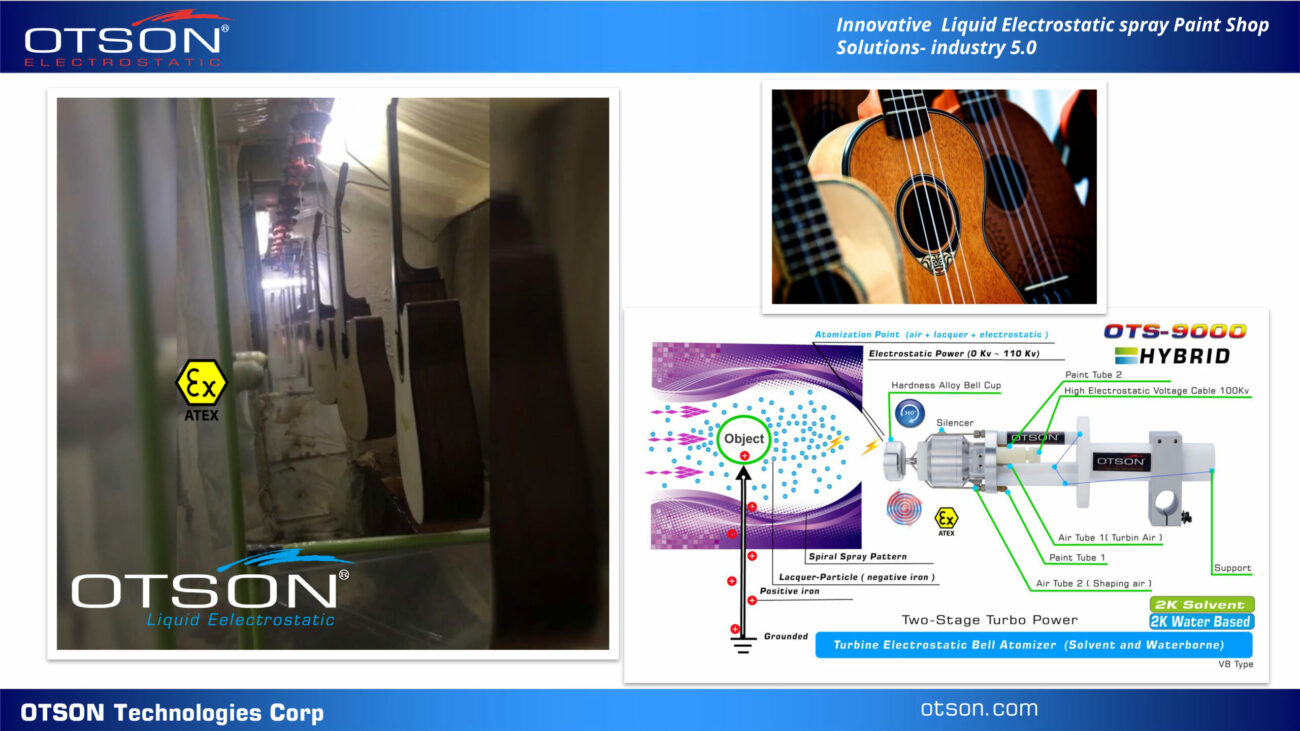

Liquid Electrostatic Spray Technology: Enhancing Aesthetics and Durability in the Musical Instruments Industry

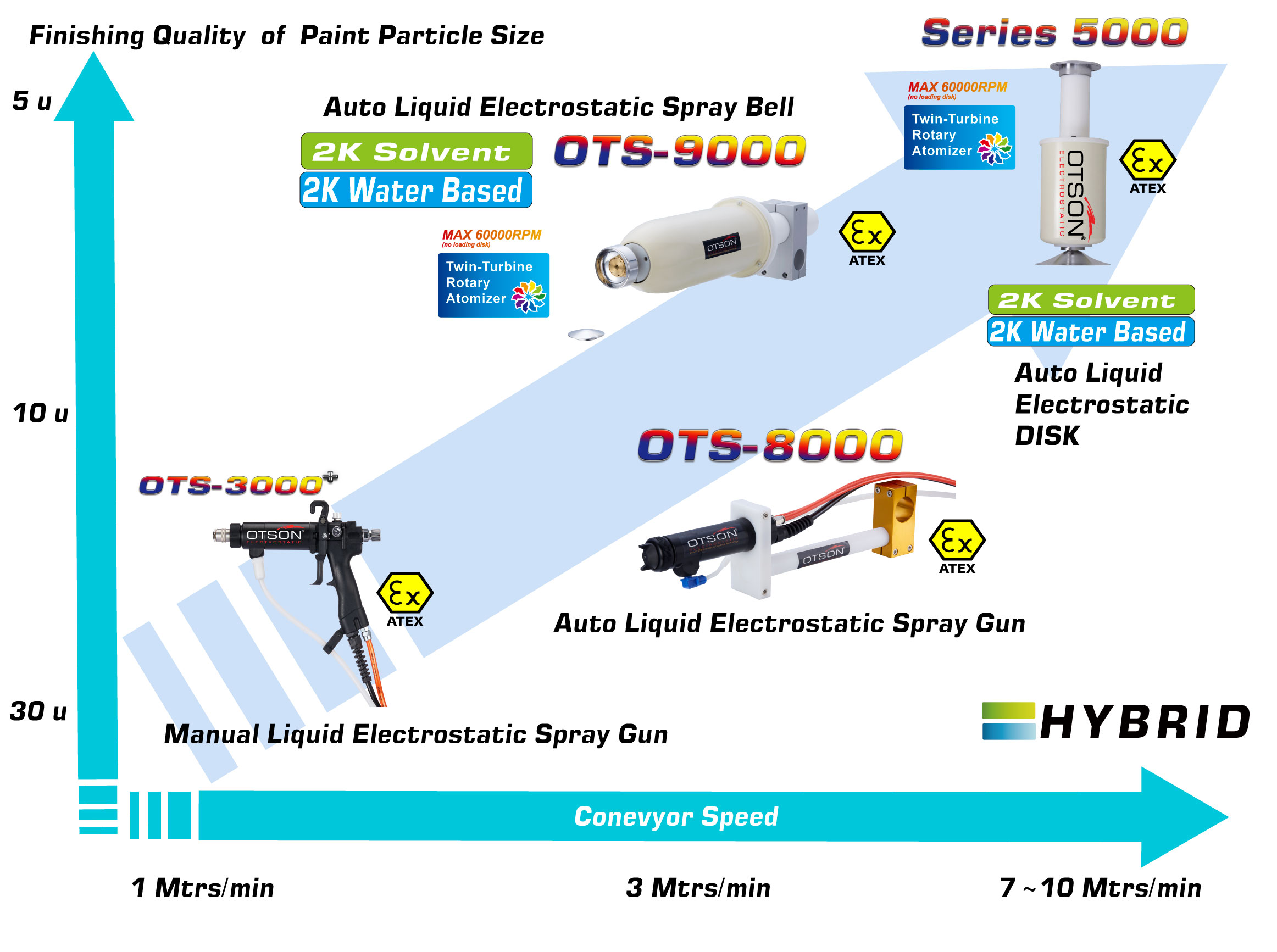

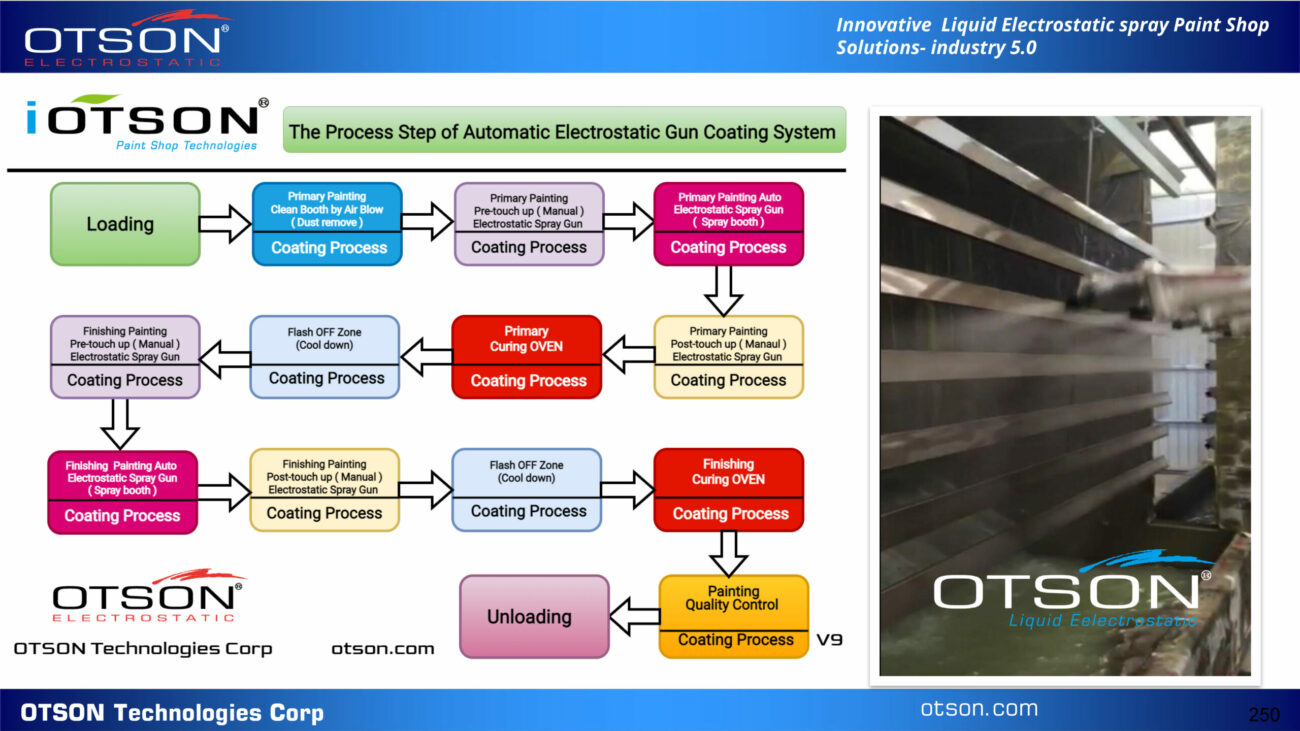

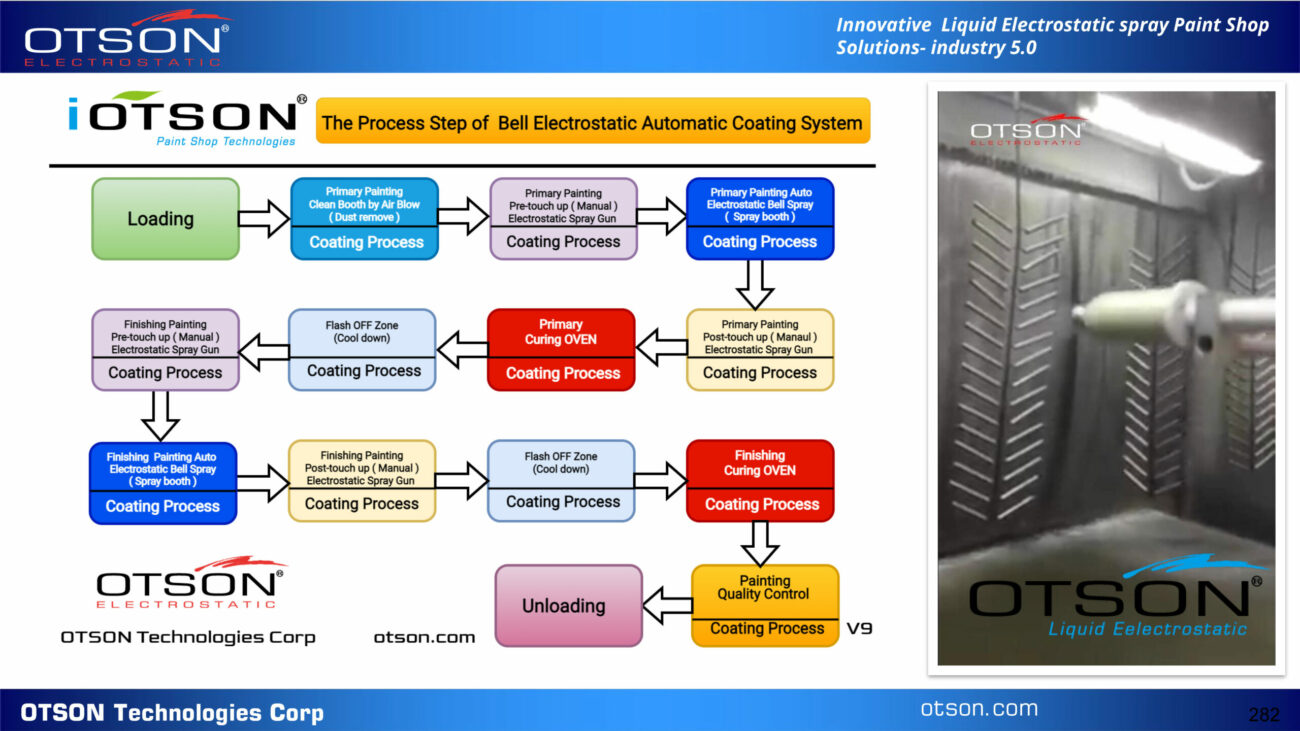

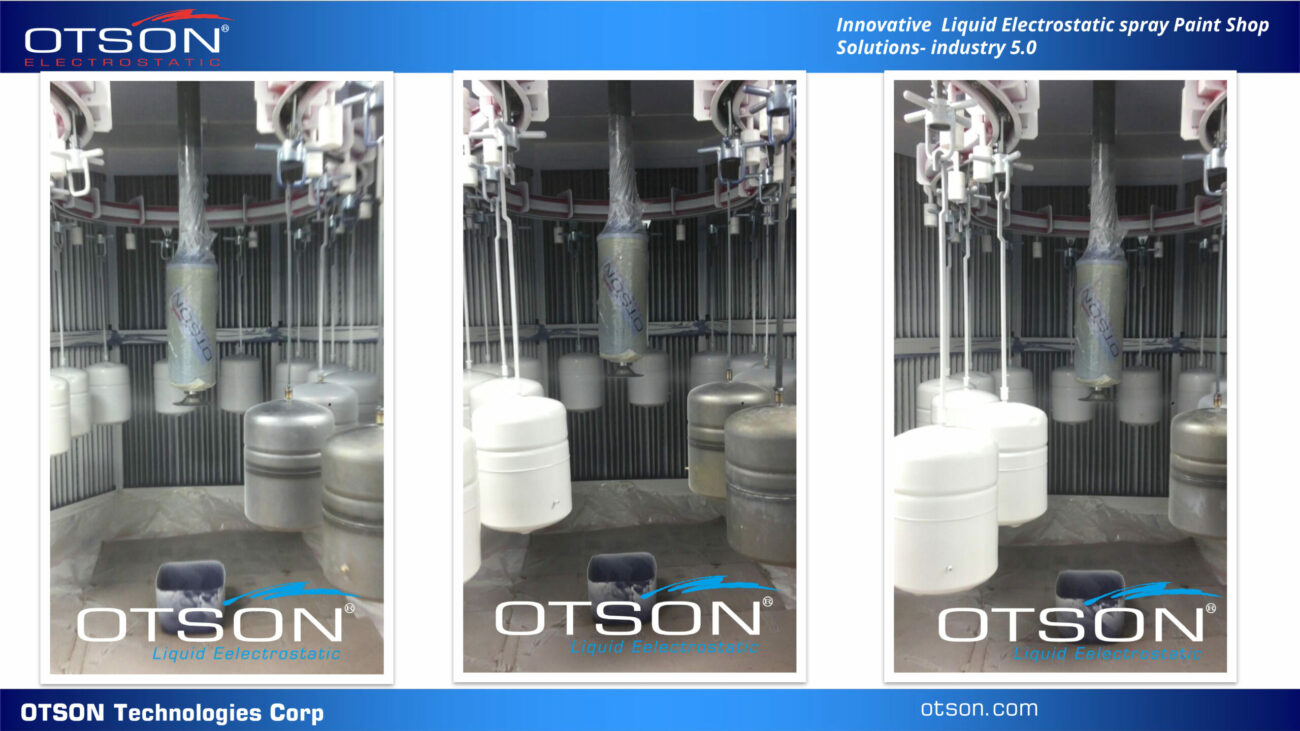

In the musical instruments industry, liquid electrostatic spray technology is widely employed to apply various coatings such as paint, lacquers, and other finishing materials to an array of musical instruments, including guitars, pianos, and other stringed instruments. This process entails atomizing the liquid into droplets, charging them electrostatically, and then attracting the charged droplets to the grounded musical instruments for a uniform and efficient coating.

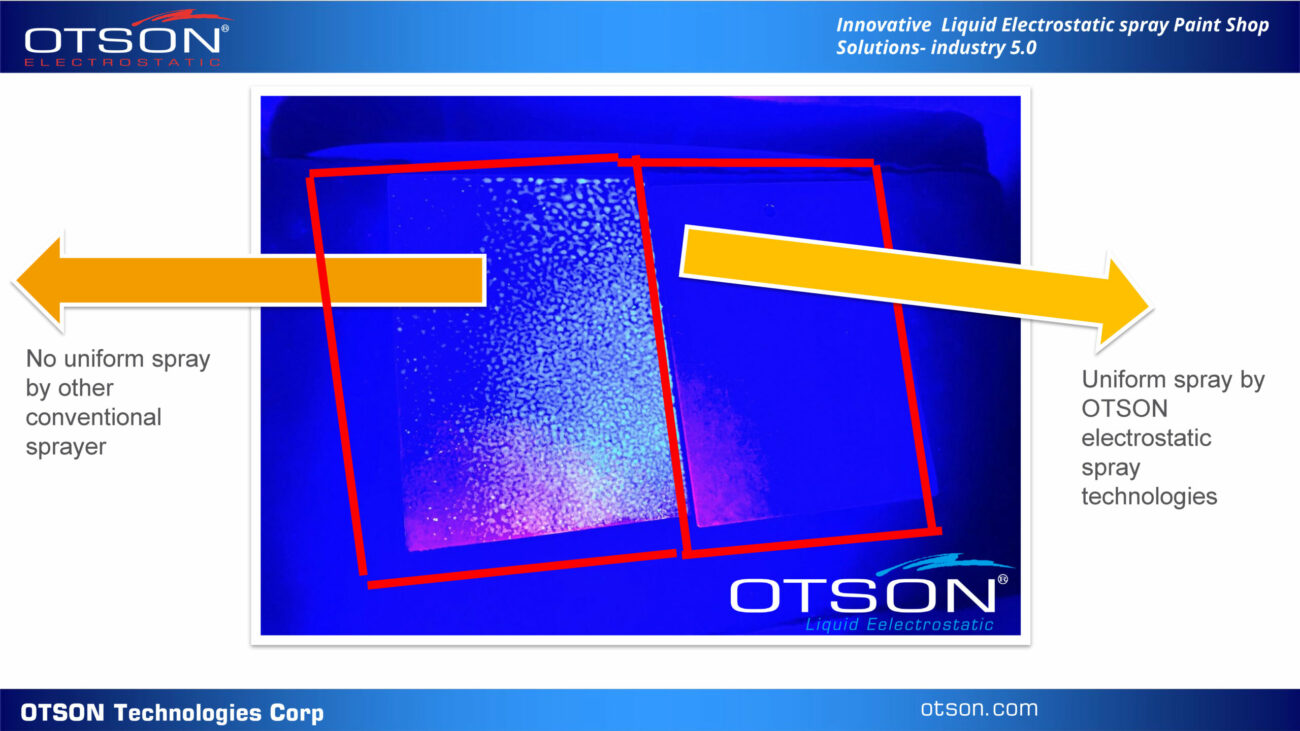

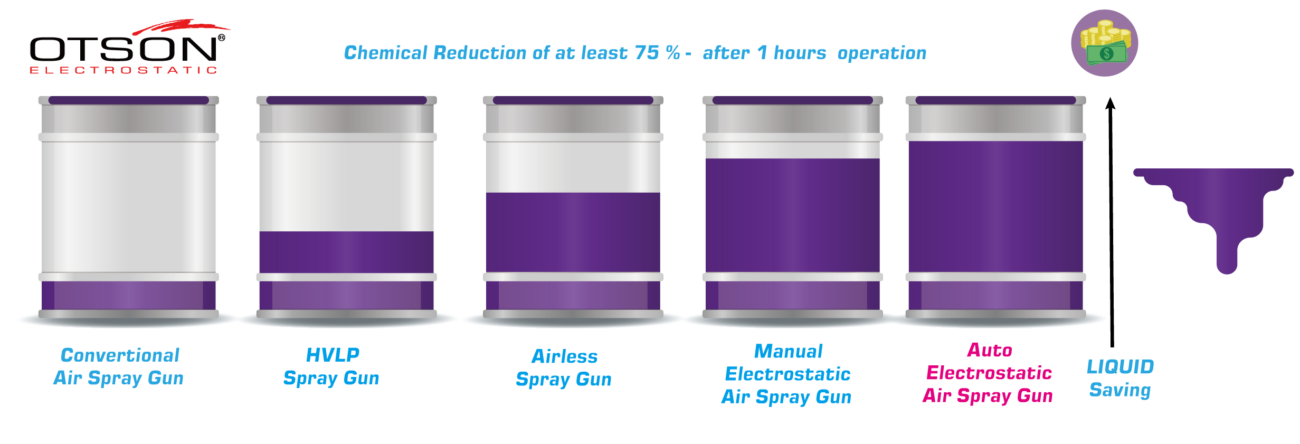

A primary advantage of using liquid electrostatic spray technology in the musical instruments industry is the increased coating savings. The electrostatic charge directs the coating droplets towards the musical instruments, resulting in less overspray and more efficient use of the coating. This leads to cost savings, as less coating is required to achieve the same coverage compared to traditional spray methods.

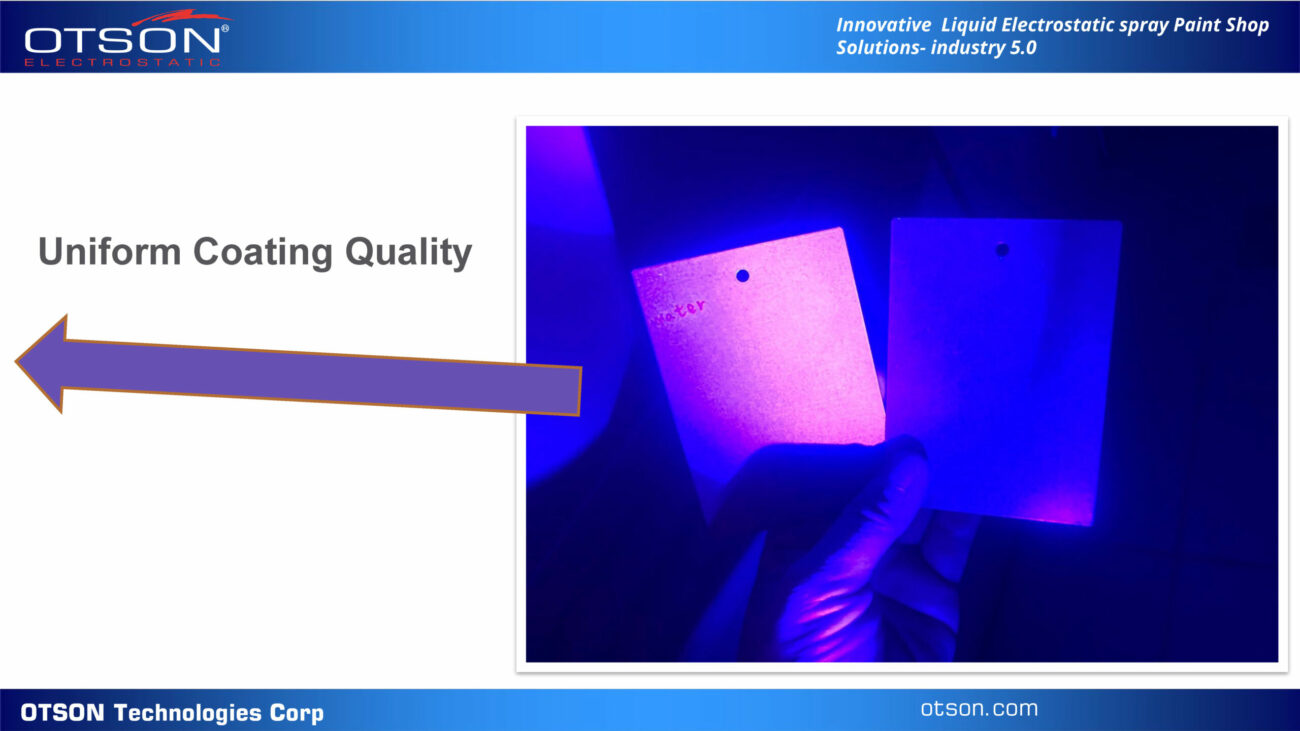

Another notable benefit is the improved transfer efficiency. The electrostatic charge ensures that a higher percentage of the coating adheres to the musical instruments, reducing wastage from overspray. This leads to a more consistent and even coating, minimizing drips and runs that could compromise the final product’s quality.

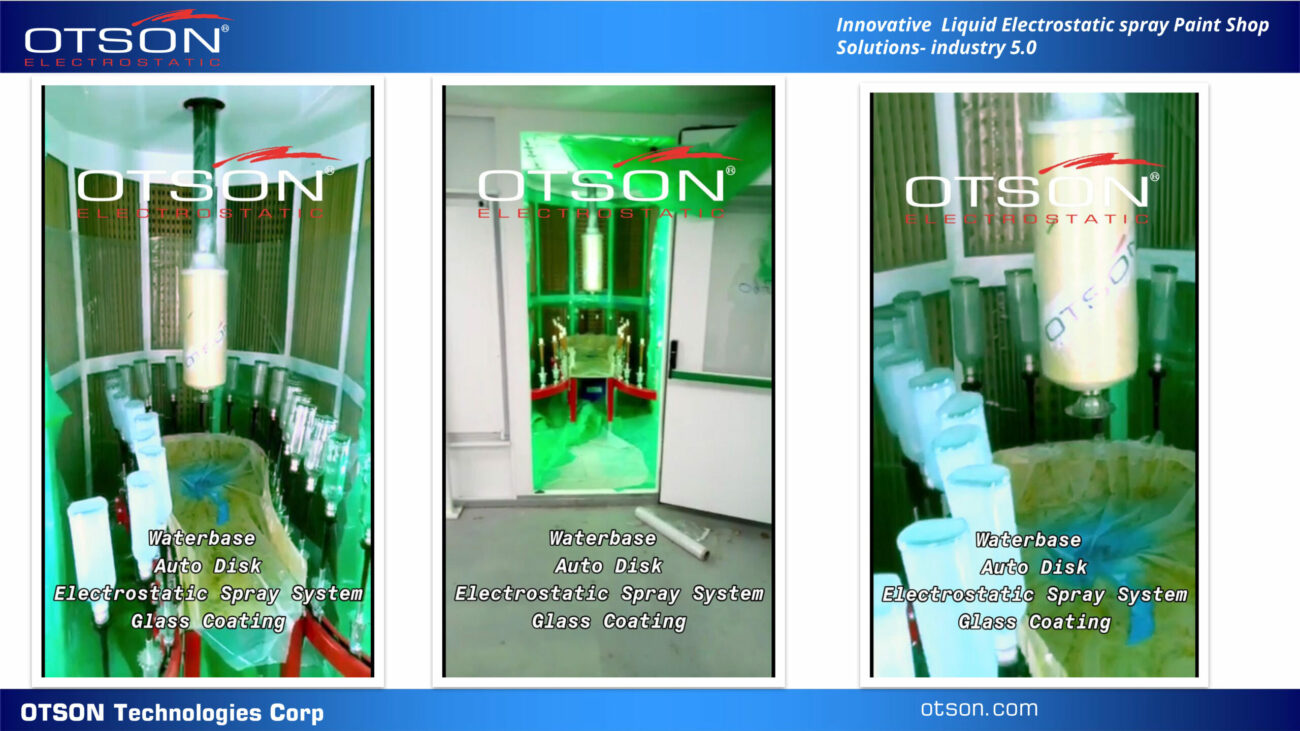

Moreover, liquid electrostatic spray technology facilitates the application of a diverse range of coatings, including paint, lacquers, and other finishing materials crucial to the musical instruments industry for enhancing the appearance and durability of the instruments.

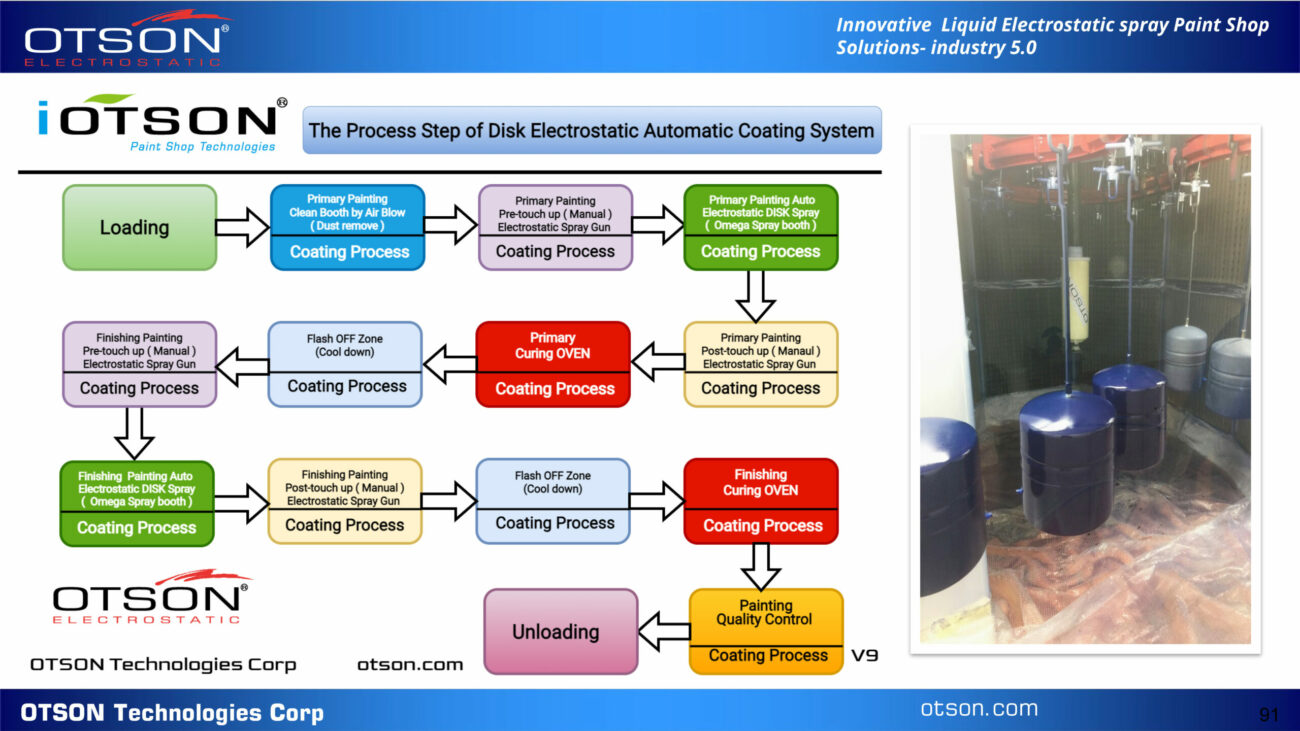

Additionally, liquid electrostatic spray technology can be employed to apply multiple layers of coating, a critical aspect for musical instruments such as guitars, pianos, and other stringed instruments that require multiple protective and durable layers against wear and tear, the elements, and to maintain the hygiene and cleanliness of the instruments.

In summary, liquid electrostatic spray technology offers a cost-effective and efficient method for applying coatings to musical instruments in the musical instruments industry. With benefits such as increased coating savings, enhanced transfer efficiency, and versatility in application, this technology plays a significant role in applying multiple layers of coating, ensuring protection, durability, and an appealing appearance while maintaining the hygiene and cleanliness of musical instruments.