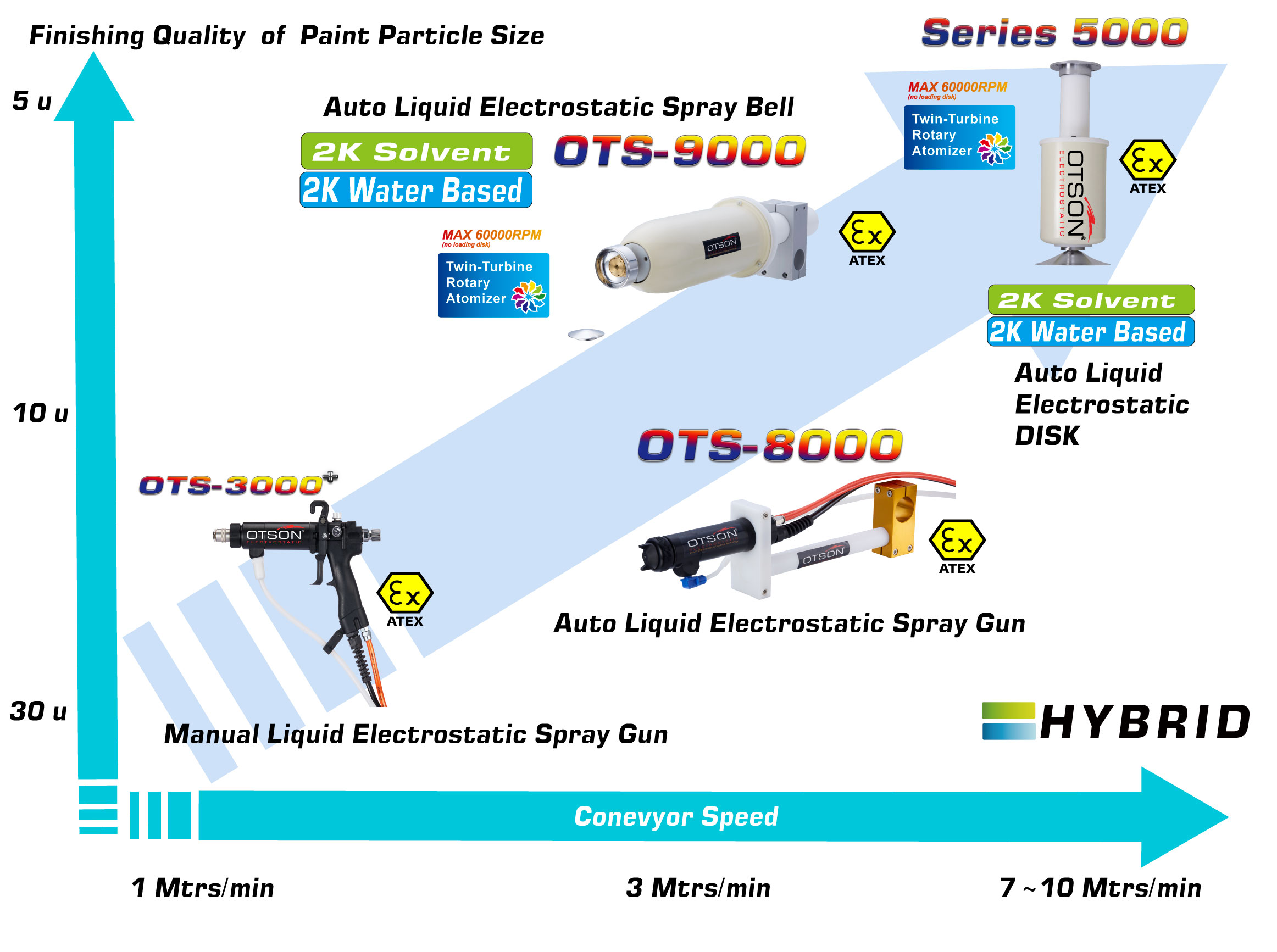

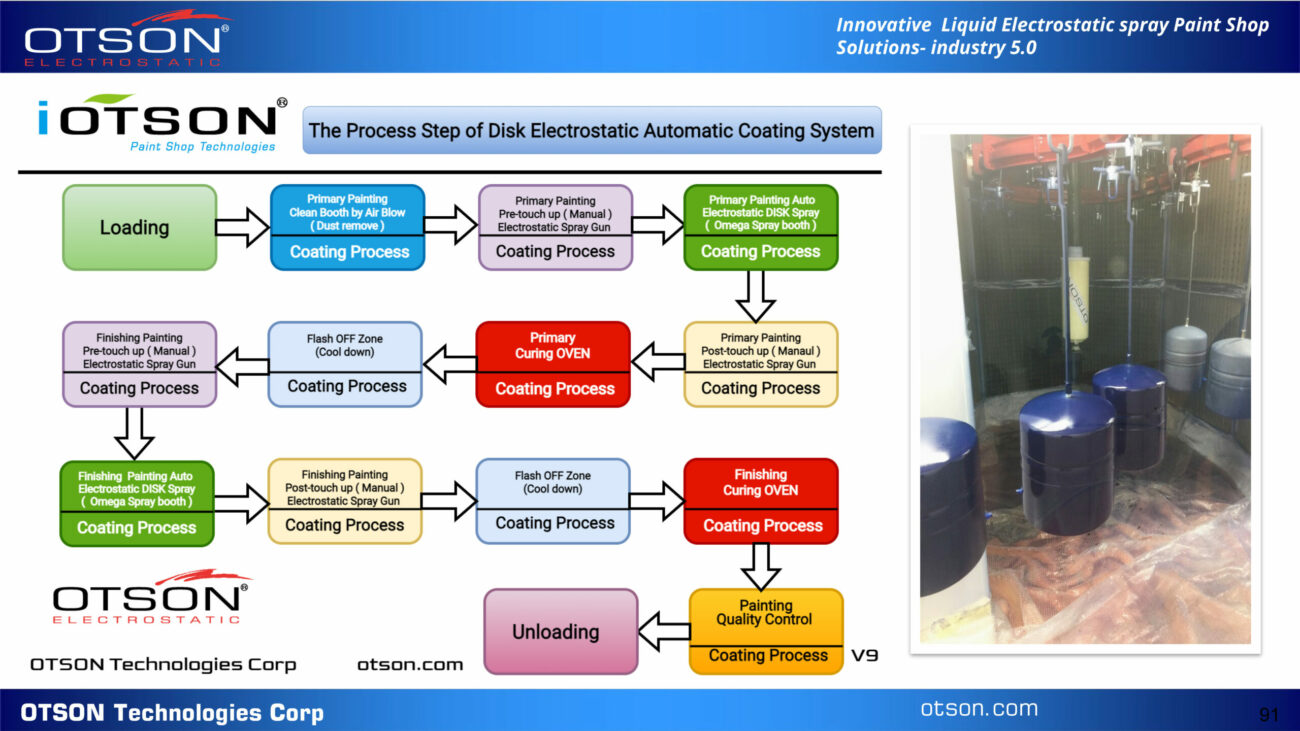

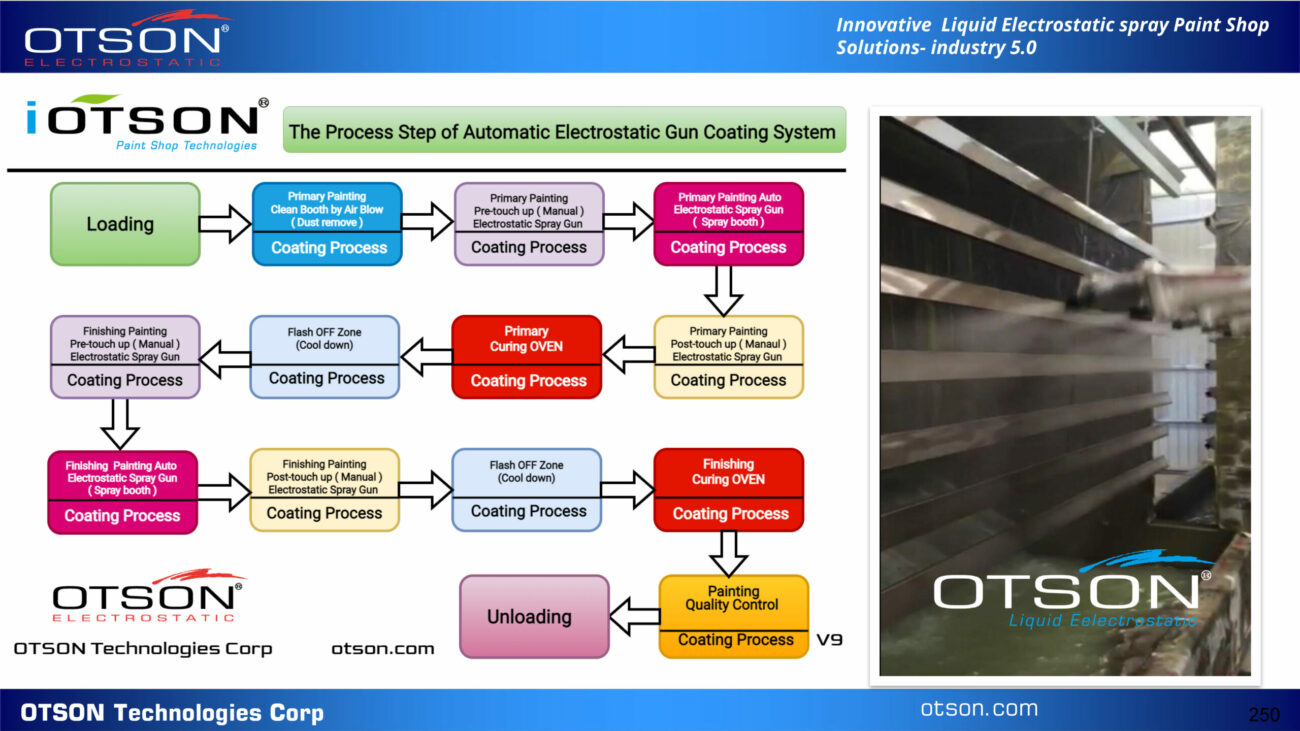

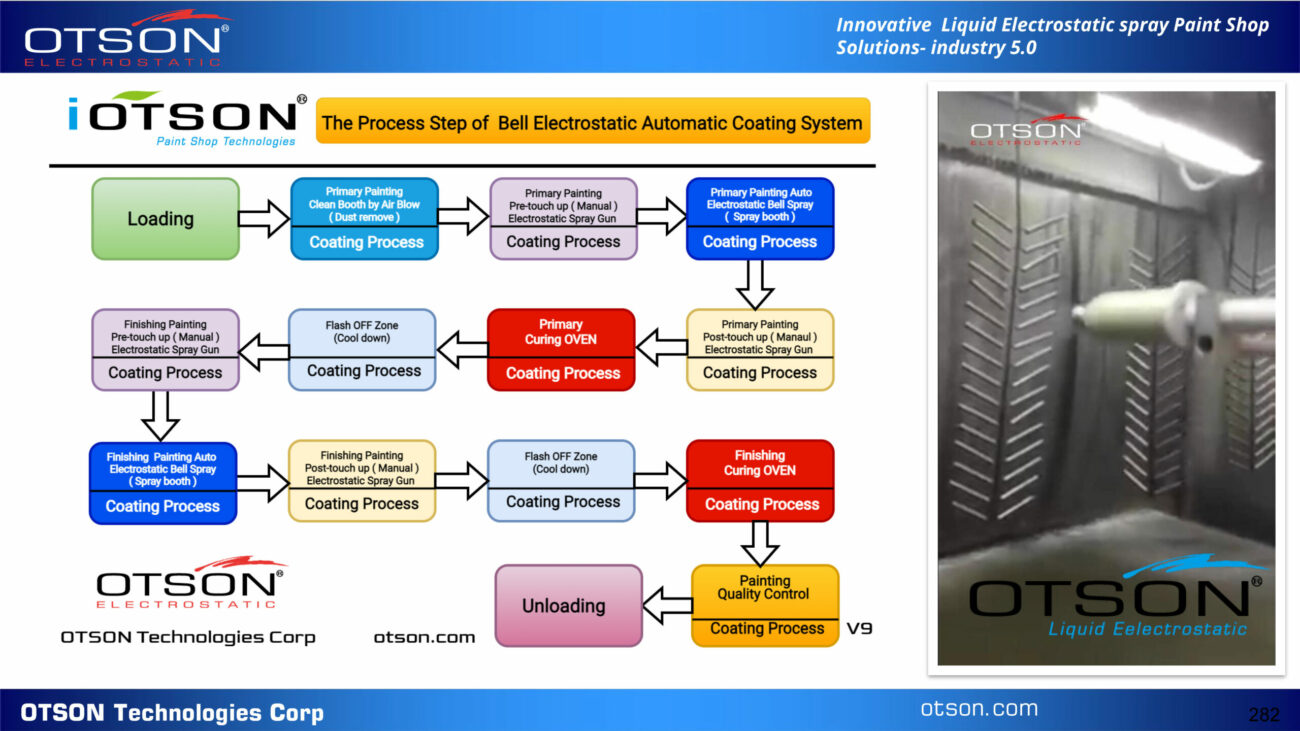

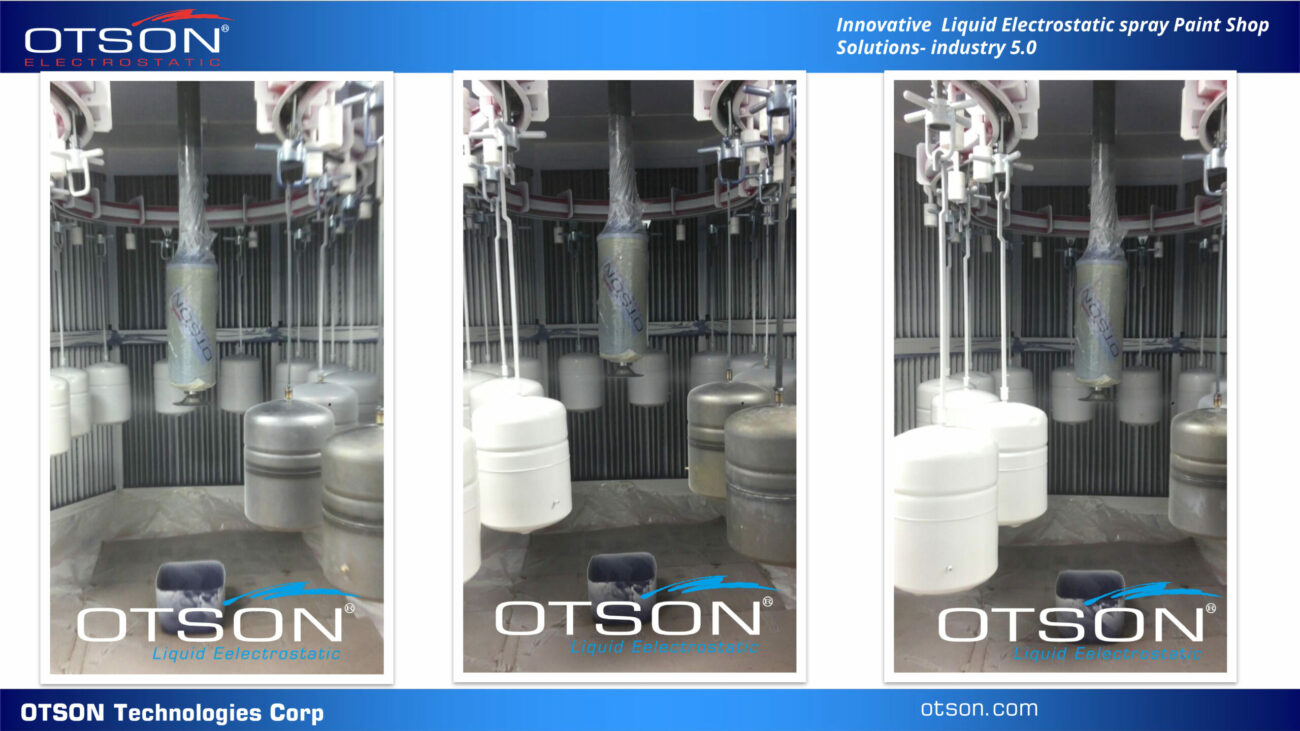

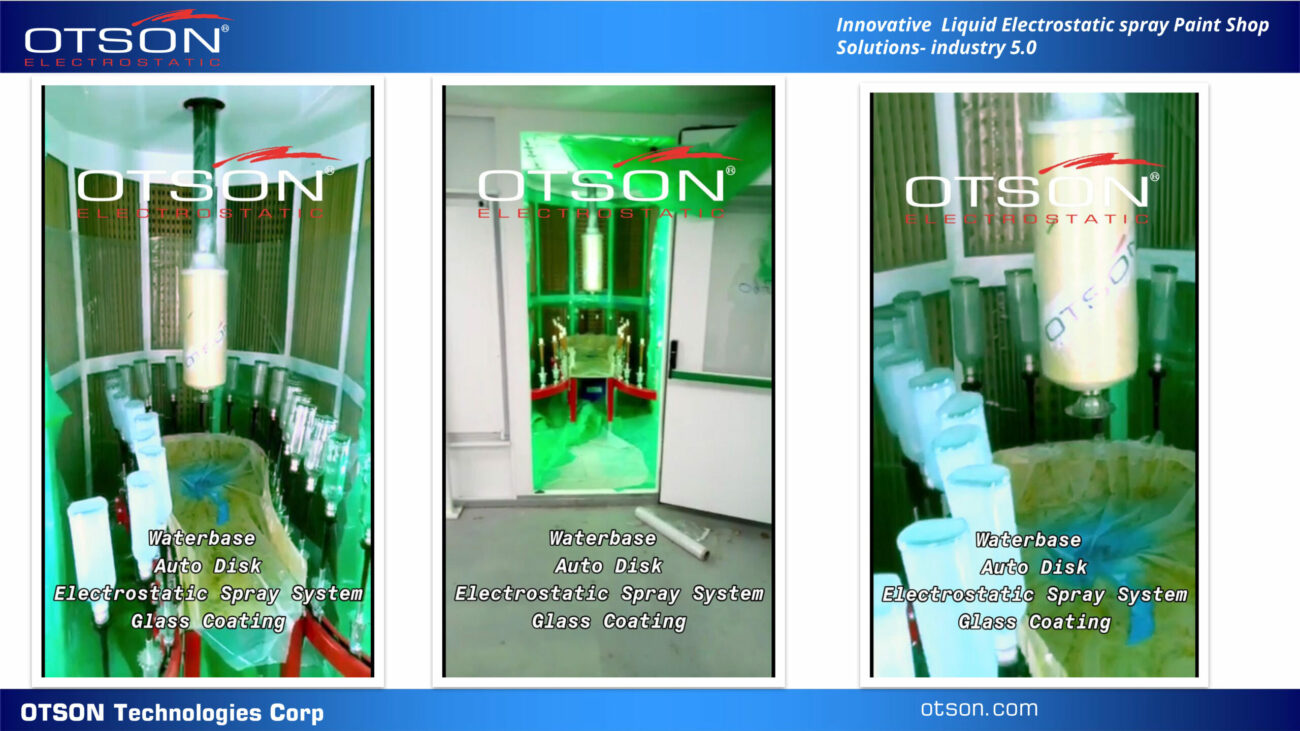

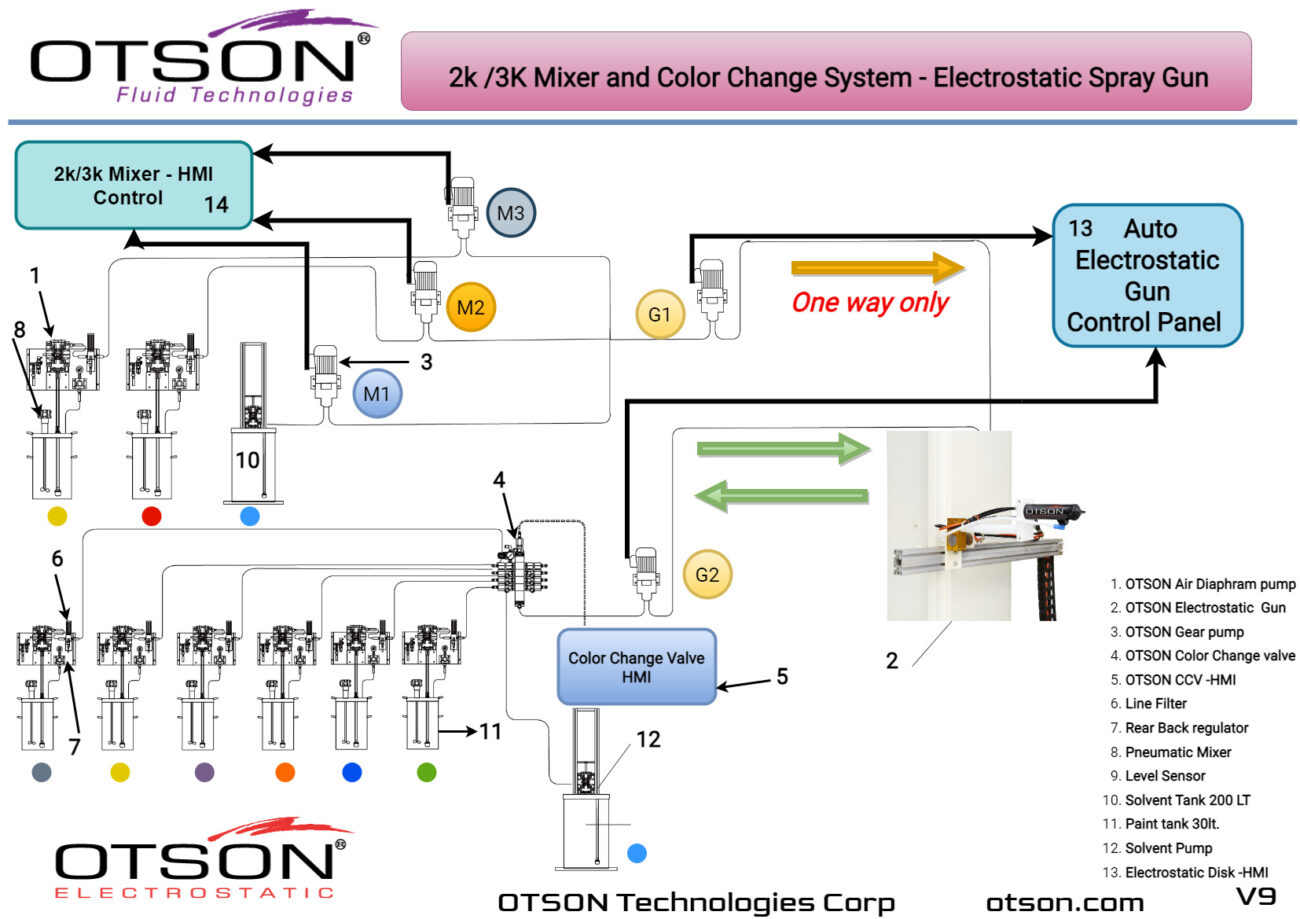

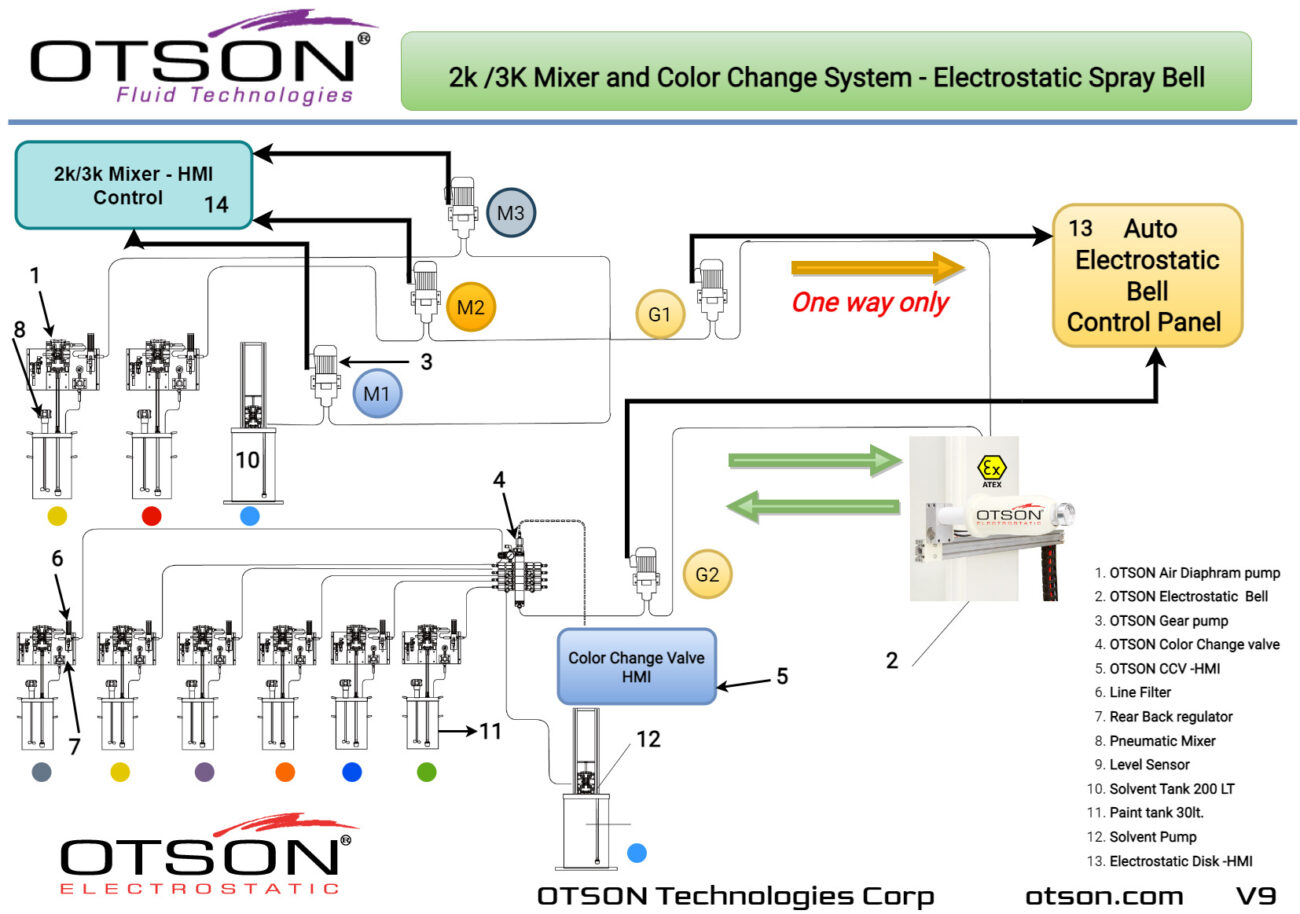

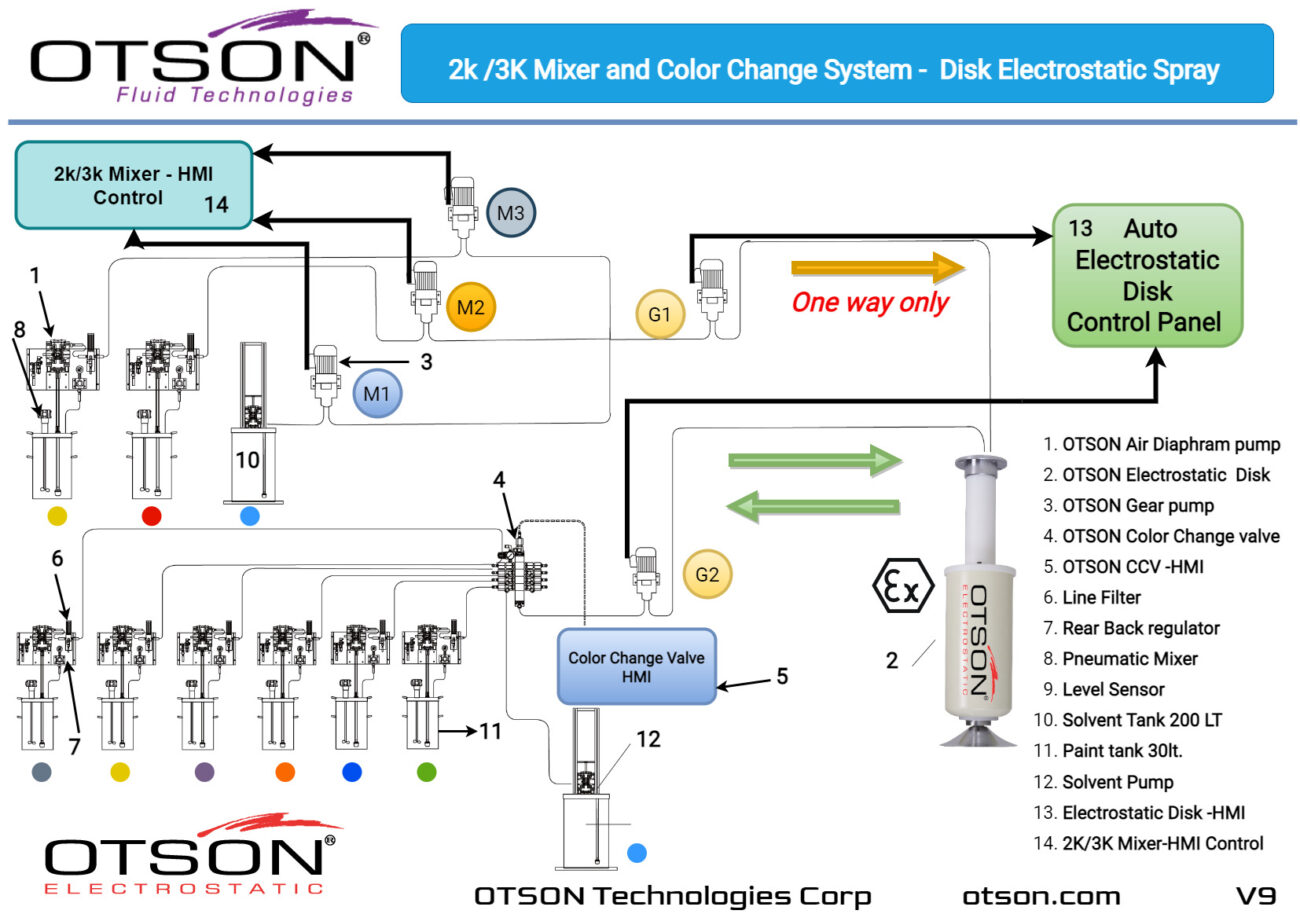

The Auto Color Change System is a technical solution for liquid electrostatic spray equipment, such as auto electrostatic spray bell, auto electrostatic spray disc, and auto electrostatic spray gun. This system is designed to provide rapid and accurate color changes for spray equipment in industrial applications, including automotive, aerospace, and other manufacturing processes.

The Auto Color Change System utilizes a series of valves and pumps to control the flow of paint and the color change process. The system is fully automated, reducing the need for manual intervention and streamlining the painting process. This makes it possible to change colors quickly and accurately, resulting in improved productivity and reduced waste.

Here are some of the key features of the Auto Color Change System:

- Fast and Accurate Color Changes: The system is designed for rapid and accurate color changes, allowing for improved productivity and reduced downtime.

- Fully Automated: The Auto Color Change System is fully automated, minimizing the need for manual intervention and streamlining the painting process.

- Versatile: The system is compatible with a wide range of paint types, including solvent-based and water-based paints, making it adaptable to various industrial applications.

- Programmable: The user-friendly interface and controls make it easy to program and operate, allowing for quick and seamless color changes.

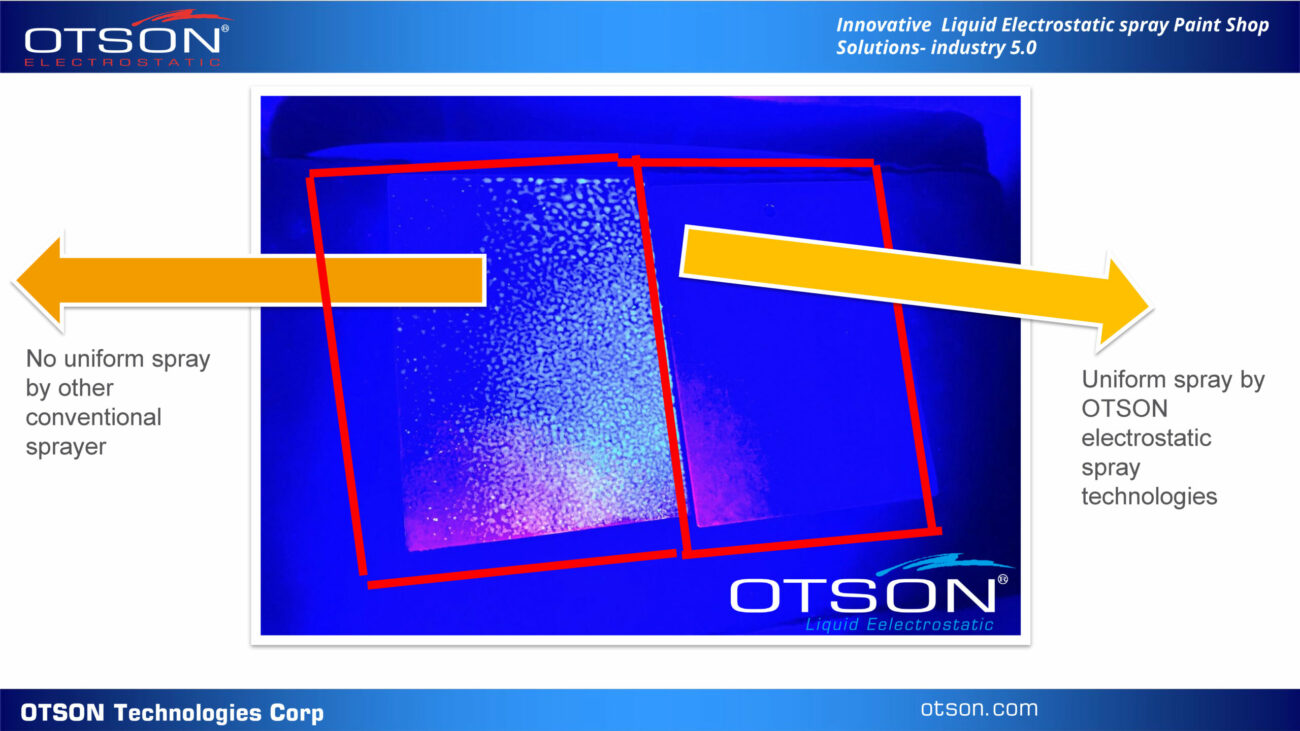

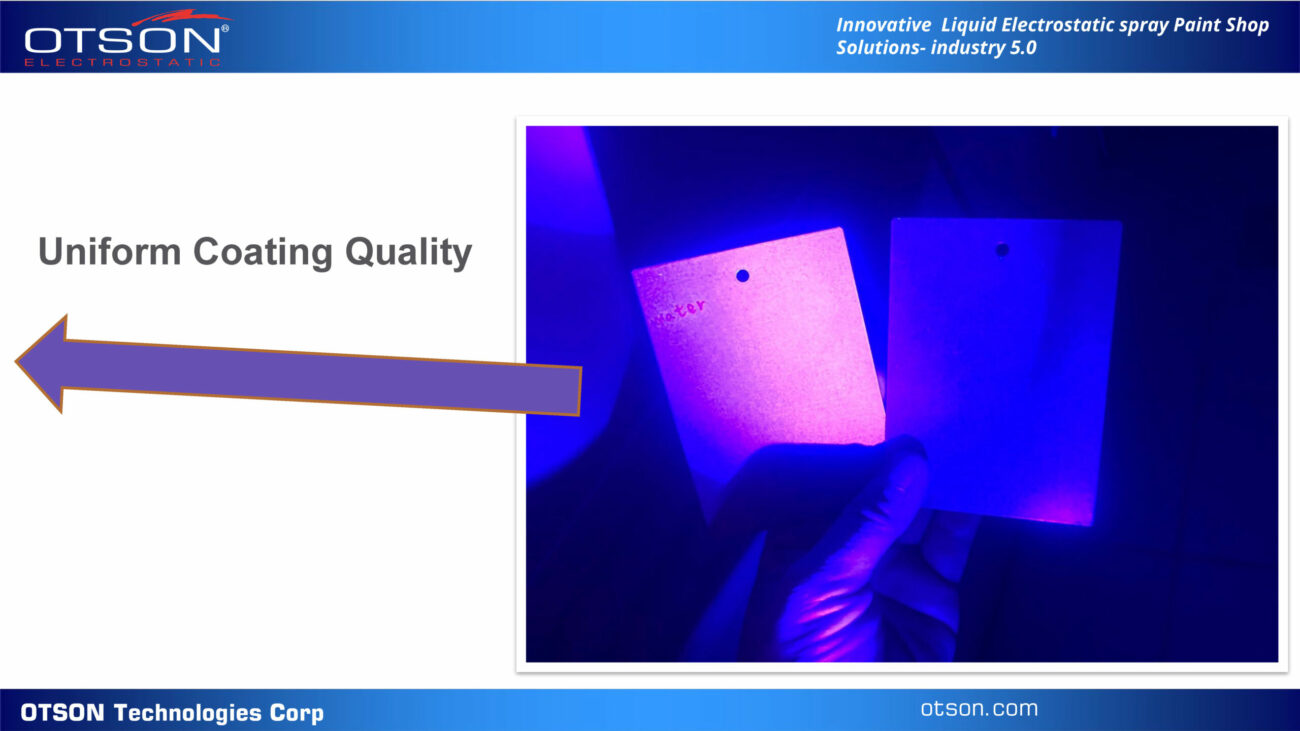

- High-Quality Finishes: The Auto Color Change System enables the application of a consistent and high-quality finish, improving the overall quality of the paint job.

- Customizable: The system can be customized to handle a range of color changes, from two to twenty or more, depending on the specific needs of the application.

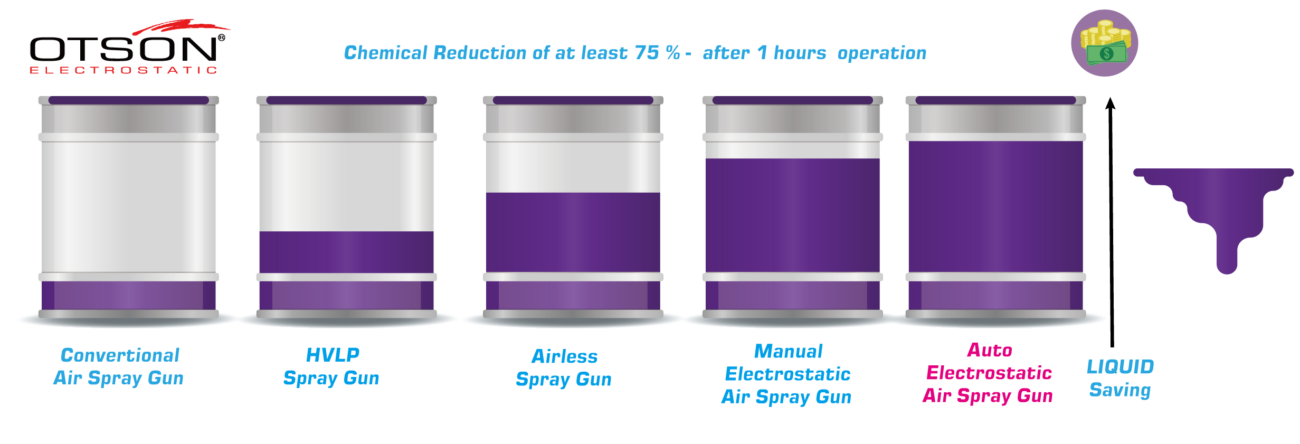

- Efficient: The system reduces waste and cleanup time, making it an efficient solution for industrial painting processes.

- Reliable: The Auto Color Change System is designed to be reliable and long-lasting, ensuring consistent performance over time.

In conclusion, the Auto Color Change System for liquid electrostatic spray equipment provides a technical solution for efficient and accurate color changes. It is an essential component of industrial painting processes, providing high-quality finishes and improving productivity while reducing waste. The system is versatile, compatible with a range of paint types, and can be customized to meet the specific needs of any industrial application. With its fully automated and programmable features, the Auto Color Change System offers a reliable and efficient solution for liquid electrostatic spray equipment.

Color change valves, also referred to as paint dispensers, are a must-have for any painting industry business. These devices are specifically designed for paint shops to accurately and quickly dispense paint, resulting in a reduction of waste and cleanup time.

One of the most notable benefits of color change valves is their ability to automatically switch between various paint colors. This feature saves time and increases efficiency, which is especially helpful for businesses that work on multiple projects and require frequent color changes.

Color change valves are also highly capable of mixing paint with hardeners, reducers, and other additives while it is being dispensed. This feature ensures that the paint is accurately mixed, improving the overall quality of the paint job.

In terms of market view, color change valves are commonly used in industrial paint applications such as automotive, aerospace, and wood finishing industries. Companies invest in color change valves to enhance their production efficiency and reduce costs.

In conclusion, color change valves are an integral part of any paint shop, providing accurate and efficient paint dispensing and color change capabilities. Investing in a top-quality color change valve can significantly increase productivity, enhance the quality of paint jobs, and ultimately save businesses money in the long run.