Electrostatic Spray Coating: A New Industry Revolution?

As the demands of industries change, and technology advances, a new revolution is sweeping the coating sector. This article dives deep into the exciting world of Electrostatic Spray Coating. Is this the New Industry Revolution? Dive in to discover more.

Introduction to Electrostatic Spray Coating

Electrostatic Spray Coating: A New Industry Revolution?

It is a question that industry experts have been mulling over, given the game-changing potential of this technology. Electrostatic spray coating, a process that leverages the principles of electrostatics to apply coatings, is dramatically changing the landscape of several industries.

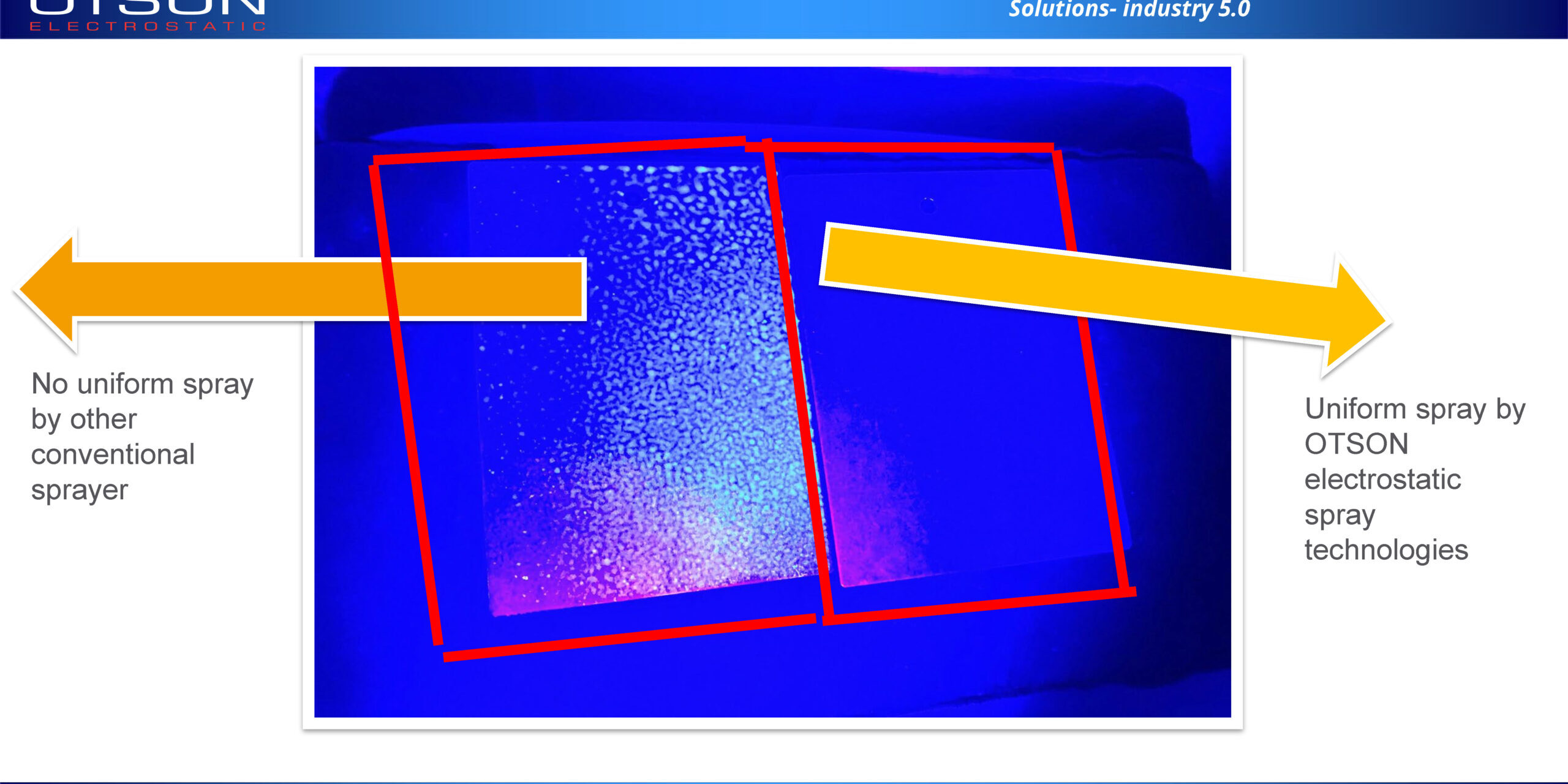

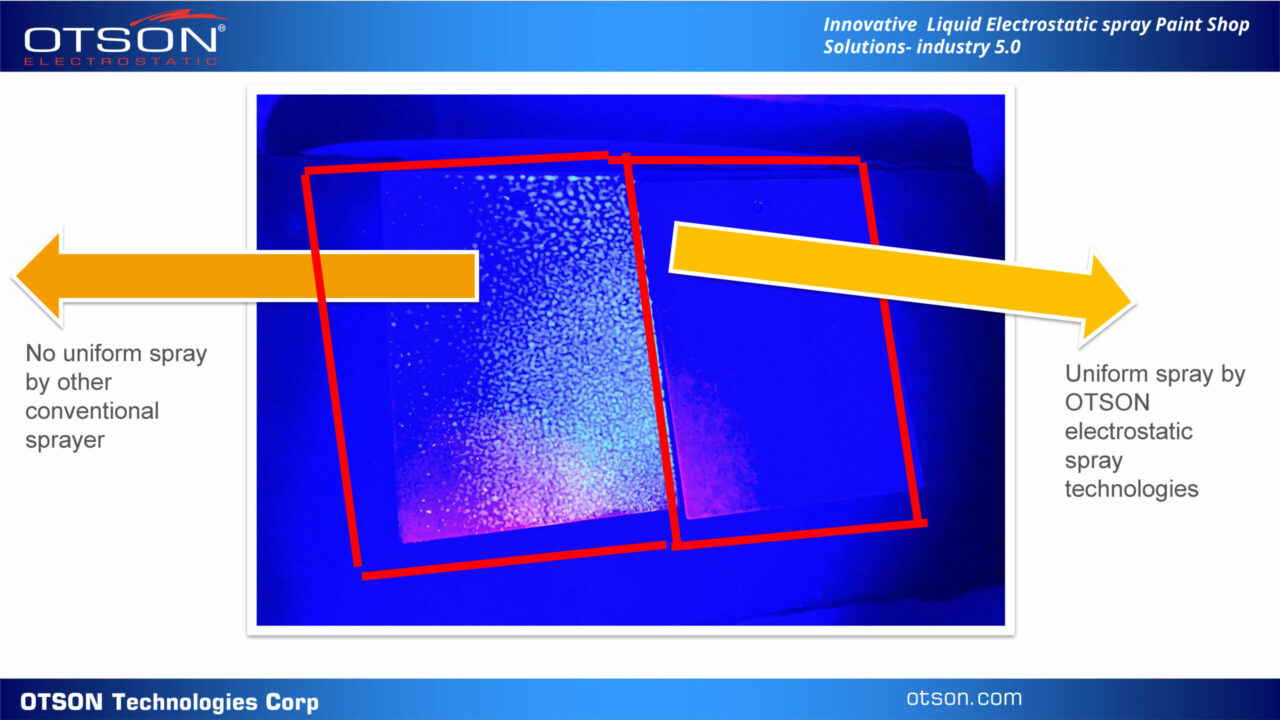

The Basics of Electrostatic Spray Coating

Here, we discuss the nuts and bolts of Electrostatic Spray Coating. This technique utilizes charged particles to ensure a more uniform distribution of paint or coating on a target surface. It offers numerous advantages over traditional coating methods.

History and Evolution of Electrostatic Spray Coating

While electrostatic spray coating may seem like a product of recent technological advancements, it has been around for several decades. This section delves into its historical progression and the various milestones it has hit on its journey.

Key Industries Leveraging Electrostatic Spray Coating

Electrostatic Spray Coating isn’t limited to a specific industry. In fact, its versatility is one of its greatest strengths. It has become an essential part of sectors ranging from automotive to aerospace, woodworking, and beyond.

Electrostatic Spray Coating in the Automotive Industry

In this competitive industry, electrostatic spray coating is a key factor in enhancing the finish and durability of vehicles. We will explore its impact and significance in automotive manufacturing.

Aerospace Industry and Electrostatic Spray Coating

The aerospace industry requires high precision and superior quality. Here, we delve into how electrostatic spray coating is meeting these demands and transforming aerospace manufacturing.

Impact of Electrostatic Spray Coating on the Woodworking Industry

In the woodworking industry, where aesthetics and durability are of prime importance, electrostatic spray coating plays a crucial role. Discover how this innovative technology is influencing the sector.

Advantages of Electrostatic Spray Coating

Wondering why Electrostatic Spray Coating is being hailed as a game-changer? Its advantages tell the story. From superior finish quality to environmental friendliness, this technology is delivering on multiple fronts.

Enhanced Efficiency and Coverage

One of the key advantages of electrostatic spray coating is the improved efficiency it brings. Learn how this technology maximizes coverage and minimizes waste, leading to significant cost savings.

Environmental Friendliness of Electrostatic Spray Coating

In an era where sustainability is paramount, electrostatic spray coating shines. This section will cover how this technique helps in reducing CO2 emissions and contributes to energy-saving goals.

Challenges and Solutions in Electrostatic Spray Coating

Despite its significant benefits, there are challenges to adopting electrostatic spray coating. However, with every challenge comes an opportunity for a solution.

Managing High Initial Costs

While electrostatic spray coating offers significant long-term benefits, its initial costs can be daunting. We will discuss how businesses are managing these costs and maximizing their return on investment.

Training and Skill Development for Electrostatic Spray Coating

Like any advanced technology, mastering electrostatic spray coating requires specific skills. Learn about the training programs and initiatives aimed at equipping the workforce with these essential skills.

The Future of Electrostatic Spray Coating

If we take a look into the future, it is clear that Electrostatic Spray Coating will continue to play a significant role in industry development. Here’s what we can expect in the years to come.

Influence of Industry 5.0 on Electrostatic Spray Coating

The onset of Industry 5.0 brings with it exciting possibilities for electrostatic spray coating. Explore how advancements in AI, robotics, and other cutting-edge technologies are influencing this field.

Electrostatic Spray Coating: A Key Player in Green Manufacturing

As industries shift towards more sustainable practices, electrostatic spray coating is expected to be a key player. Learn about its role in promoting green manufacturing.

Frequently Asked Questions

What is Electrostatic Spray Coating?

Electrostatic Spray Coating is a technique that uses the principles of electrostatics to apply a coating or paint to a surface, ensuring a uniform distribution.

Why is Electrostatic Spray Coating considered revolutionary?

This technique is considered revolutionary because it provides a superior finish, reduces waste, enhances efficiency, and contributes to sustainability goals.

In which industries is Electrostatic Spray Coating used?

It is used across numerous sectors including automotive, aerospace, and woodworking, among others.

What are the challenges in adopting Electrostatic Spray Coating?

While offering numerous benefits, the challenges include high initial investment and the need for specific skill sets and training.

What is the future of Electrostatic Spray Coating?

The future of Electrostatic Spray Coating is promising, with potential advancements in Industry 5.0 and its critical role in promoting green manufacturing.

Conclusion

So, is Electrostatic Spray Coating a new industry revolution? Considering its wide-ranging benefits, adoption across industries, and the future potential it holds, it indeed seems so.