Curing Oven-Paint Shop

Curing ovens are industrial ovens that are used to cure (harden) coatings, paints, adhesives, and other materials by exposing them to heat. There are several types of curing ovens available, including:

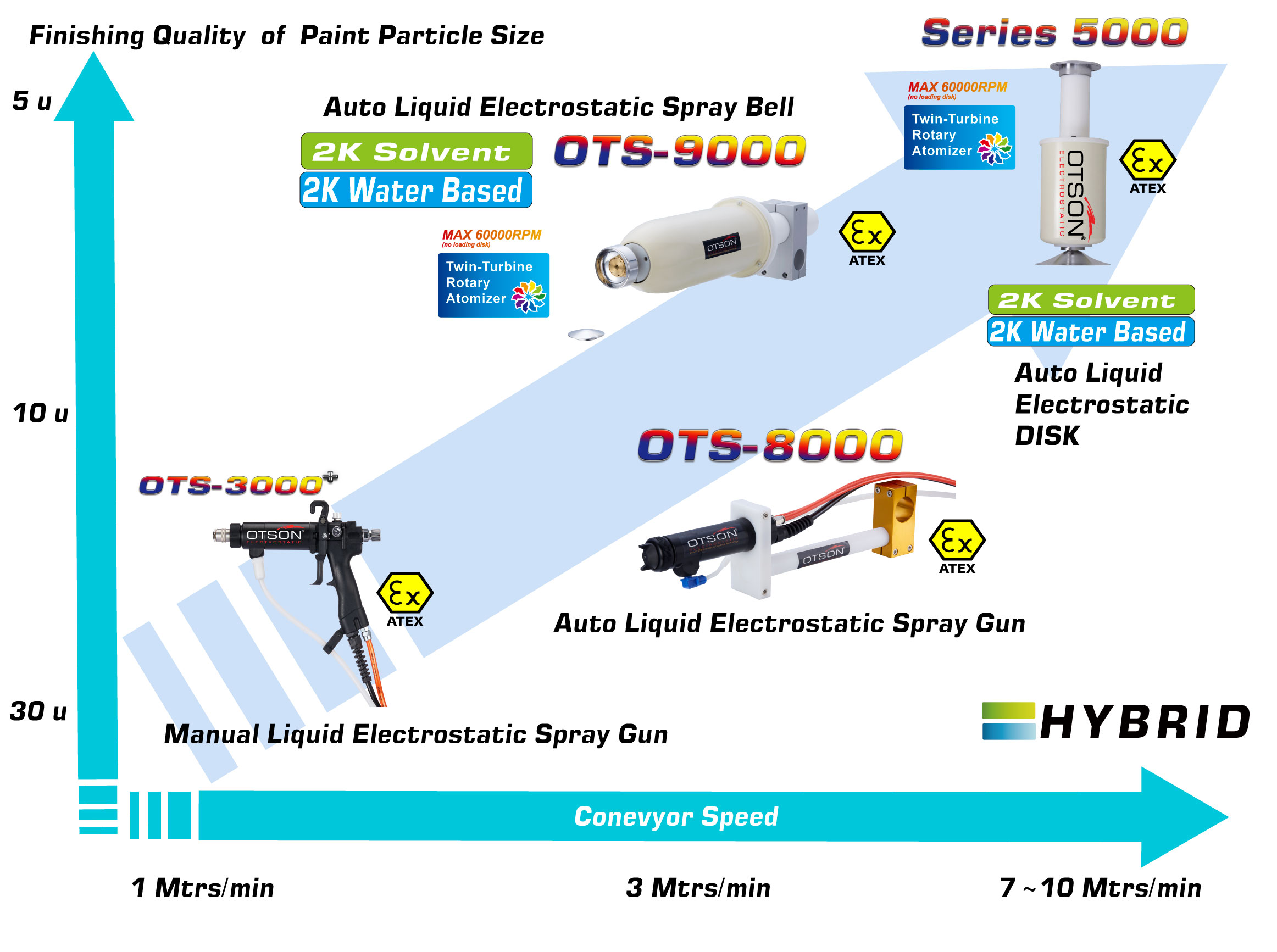

OTS-3000 Manual Liquid Electrostatic Spray Gun- ( Digital Version ) G7

OTS-3000 Manual Liquid Electrostatic Spray Gun- ( Digital Version ) G7 OTS-5000 -Disk ( Disc ) Electrostatic -Automatic Coating System

OTS-5000 -Disk ( Disc ) Electrostatic -Automatic Coating System OTS-7800 Auto Electrostatic Spray Gun Kit – Robot Arm

OTS-7800 Auto Electrostatic Spray Gun Kit – Robot Arm OTS-7900 Auto Electrostatic Spray Bell Kit -Robot Arm

OTS-7900 Auto Electrostatic Spray Bell Kit -Robot Arm OTS-8000 Auto Electrostatic Spray Gun System

OTS-8000 Auto Electrostatic Spray Gun System OTS-9000 Auto Electrostatic Spray Bell System

OTS-9000 Auto Electrostatic Spray Bell System OTS-3-B – Paint Resistivity Meter -Digital Version

OTS-3-B – Paint Resistivity Meter -Digital Version OTS-7-B – Electrostatic Power Test Meter -Digital Version

OTS-7-B – Electrostatic Power Test Meter -Digital Version OTS-3000 Manual Liquid Electrostatic Spray Gun- ( Digital Version ) G7

OTS-3000 Manual Liquid Electrostatic Spray Gun- ( Digital Version ) G7 OTS-5000 -Disk ( Disc ) Electrostatic -Automatic Coating System

OTS-5000 -Disk ( Disc ) Electrostatic -Automatic Coating System OTS-7800 Auto Electrostatic Spray Gun Kit – Robot Arm

OTS-7800 Auto Electrostatic Spray Gun Kit – Robot Arm OTS-7900 Auto Electrostatic Spray Bell Kit -Robot Arm

OTS-7900 Auto Electrostatic Spray Bell Kit -Robot Arm OTS-8000 Auto Electrostatic Spray Gun System

OTS-8000 Auto Electrostatic Spray Gun System OTS-9000 Auto Electrostatic Spray Bell System

OTS-9000 Auto Electrostatic Spray Bell System OTS-3-B – Paint Resistivity Meter -Digital Version

OTS-3-B – Paint Resistivity Meter -Digital Version OTS-7-B – Electrostatic Power Test Meter -Digital Version

OTS-7-B – Electrostatic Power Test Meter -Digital Version

Curing ovens are industrial ovens that are used to cure (harden) coatings, paints, adhesives, and other materials by exposing them to heat. There are several types of curing ovens available, including:

In general, the type of curing oven that is best suited for a particular application will depend on the specific material being cured, the desired curing speed and efficiency, and the available space and budget. It is important to choose an oven that is appropriate for the specific needs of the application to ensure optimal results.

OTSON Technologies Corp. is a well-known provider of cutting-edge paint shop solutions for various industrial and commercial markets. Our extensive range of products and services are designed to help our clients improve their painting processes, reduce costs, and increase overall efficiency. With years of experience as a reputable manufacturer, we take pride in delivering high-quality products and services to meet the needs of our valued customers.

One of our flagship products is the OTSON Liquid Electrostatic, which features innovative technology and patented designs for electrostatic liquid coating and fluid transfer applications. Our product range includes a wide variety of equipment options such as disc and bell systems that cater to the unique requirements of various industries and applications.

OTSON Liquid Electrostatic systems are renowned for their precision, high efficiency, and reliability. Our products are specifically designed to minimize paint waste and increase production rates, resulting in a significant return on investment for our customers. Furthermore, our systems meet industry safety standards with ATEX certification, ensuring the delivery of high-quality finishes to our clients.

At OTSON, we understand the significance of offering complete solutions to cater to the diverse needs of our clients. Therefore, we are committed to integrating our OTSON Liquid Electrostatic systems with our smart paint shop solutions that provide greater process control, enhanced efficiency, and improved quality.

If you are looking for a reliable and efficient liquid electrostatic coating system, OTSON’s OTSON Liquid Electrostatic line is the perfect choice. Get in touch with us today to learn more about our products and services, and how they can benefit your business.

Electrostatic spray coating is a popular choice for mass production factories due to the many benefits it offers over traditional coating methods. Some of the key advantages of using electrostatic spray coating include:

Overall, electrostatic spray coating is a versatile, efficient, and sustainable method that is widely used in various industries, including automobiles, bicycles, wheels, instrumentation, electrical appliances, agricultural machinery, household electrical appliances, daily hardware, steel furniture, doors, windows, power tools, toys, gas appliances, and other industrial fields. The benefits of electrostatic spray coating make it an ideal choice for businesses looking to improve their coating processes, reduce costs, and increase efficiency while reducing their environmental impact.

Electrostatic spraying is a highly efficient and cost-effective coating method that has become increasingly popular across a range of industries. Here are some key features and benefits of using electrostatic spray equipment in your paint shop:

Overall, electrostatic spray equipment can provide a wide range of benefits for paint shops, from increased efficiency and improved coating quality to greater flexibility and increased safety. With its relatively low initial investment cost and short payback period, it can be a cost-effective and environmentally-friendly solution that can improve the ROI of your paint shop operations.

Water-based electrostatic spray coating has a variety of features that make it a popular and environmentally friendly coating option. Here are some of the key features of this process:

Overall, water-based electrostatic spray coating is an environmentally friendly and high-quality coating process that can be used on a wide range of substrates and products. Its specialized equipment and proprietary technology make it a versatile solution for many different industries.

Spray System | Productive rate | Spray Pattern | Paints Consumption | Atomizing Performance | Spray Booth Style |

Excellent: Coating works is done simultaneously for all objects around Disk atomizer | Good for mass production Disk Reciprocator stroke distance could be customized according to hanger size ( Conveyor speed is workable for 7Mtrs/min ) | Low: High atomizing performance is achieved by OTSON precision structure. | Excellent ( 60,000 RPM) | OMEGA Spray Booth | |

Good: Bell Cup atomizer stroke from down to up Note: by Bell system, it is not suitable for rotating hangers | High atomizing Bell Cup, spray pattern is around 25cm ( Diameter ). Conveyor speed: between 1.8 Mtrs/min - 2.0 Mtrs/min suggestion | Low: High atomizing performance is achieved by OTSON precision structure. | Excellent (60,000 RPM) | Side by Side Spray Booth | |

Good: Flexible for various objects such as platform-like objects and multiple shape object | 4 types of spray pattern nozzles for options Conveyor speed: 4 Mtrs/min suggestion | Acceptable: ( Auto spray gun is driven by air, its paintings consumption will be more than Bell and disk coating system ) | Side by Side Spray Booth |

The Auto Color Change System is a technical solution for liquid electrostatic spray equipment, such as auto electrostatic spray bell, auto electrostatic spray disc, and auto electrostatic spray gun. This system is designed to provide rapid and accurate color changes for spray equipment in industrial applications, including automotive, aerospace, and other manufacturing processes.

The Auto Color Change System utilizes a series of valves and pumps to control the flow of paint and the color change process. The system is fully automated, reducing the need for manual intervention and streamlining the painting process. This makes it possible to change colors quickly and accurately, resulting in improved productivity and reduced waste.

Here are some of the key features of the Auto Color Change System:

In conclusion, the Auto Color Change System for liquid electrostatic spray equipment provides a technical solution for efficient and accurate color changes. It is an essential component of industrial painting processes, providing high-quality finishes and improving productivity while reducing waste. The system is versatile, compatible with a range of paint types, and can be customized to meet the specific needs of any industrial application. With its fully automated and programmable features, the Auto Color Change System offers a reliable and efficient solution for liquid electrostatic spray equipment.

Color change valves, also referred to as paint dispensers, are a must-have for any painting industry business. These devices are specifically designed for paint shops to accurately and quickly dispense paint, resulting in a reduction of waste and cleanup time.

One of the most notable benefits of color change valves is their ability to automatically switch between various paint colors. This feature saves time and increases efficiency, which is especially helpful for businesses that work on multiple projects and require frequent color changes.

Color change valves are also highly capable of mixing paint with hardeners, reducers, and other additives while it is being dispensed. This feature ensures that the paint is accurately mixed, improving the overall quality of the paint job.

In terms of market view, color change valves are commonly used in industrial paint applications such as automotive, aerospace, and wood finishing industries. Companies invest in color change valves to enhance their production efficiency and reduce costs.

In conclusion, color change valves are an integral part of any paint shop, providing accurate and efficient paint dispensing and color change capabilities. Investing in a top-quality color change valve can significantly increase productivity, enhance the quality of paint jobs, and ultimately save businesses money in the long run.