Customer Testimonials/Case Studies

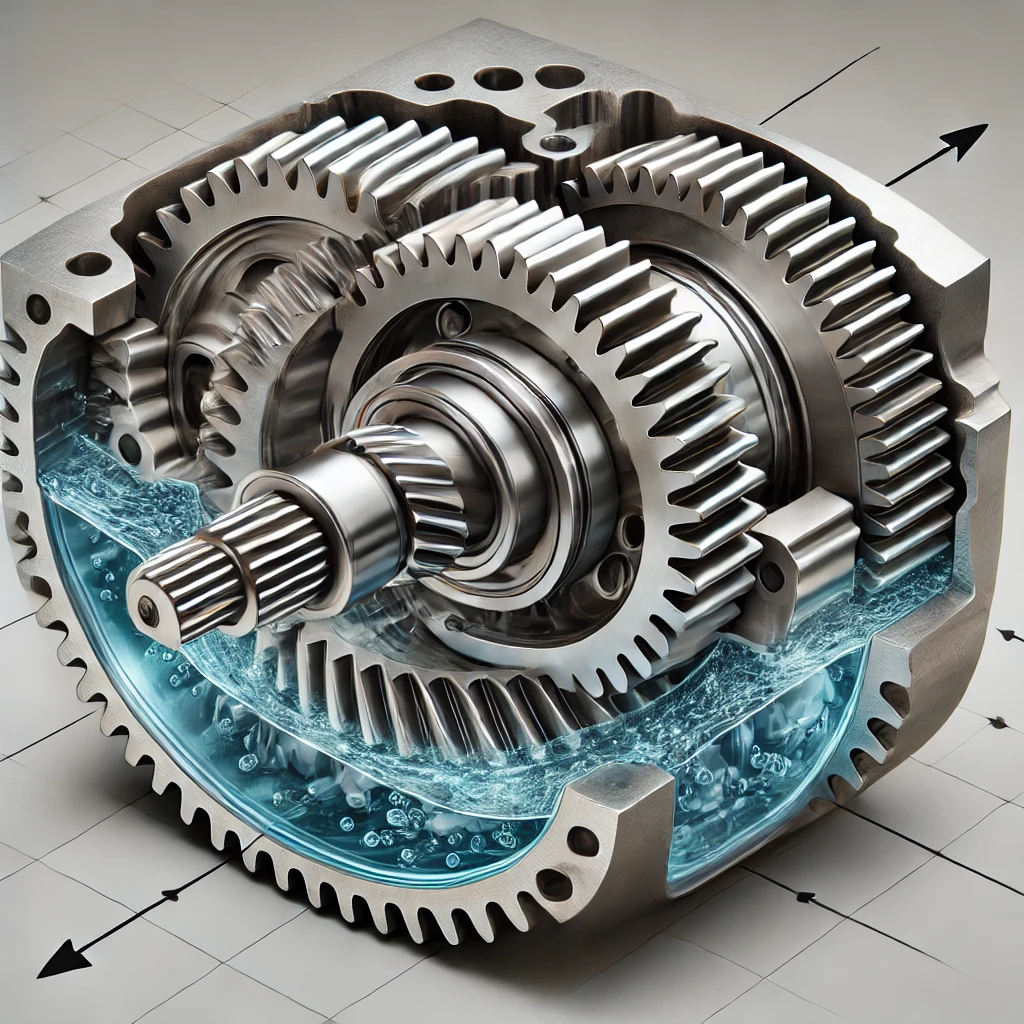

To demonstrate the real-world effectiveness of the OTS-50 Gear Pump Line, this section provides testimonials and case studies from customers who have successfully integrated our gear pumps into their operations. These examples highlight the performance improvements, cost savings, and system efficiency our customers have achieved by switching to OTSON gear pumps.

Case Study 1: Automotive Manufacturer

Challenge:

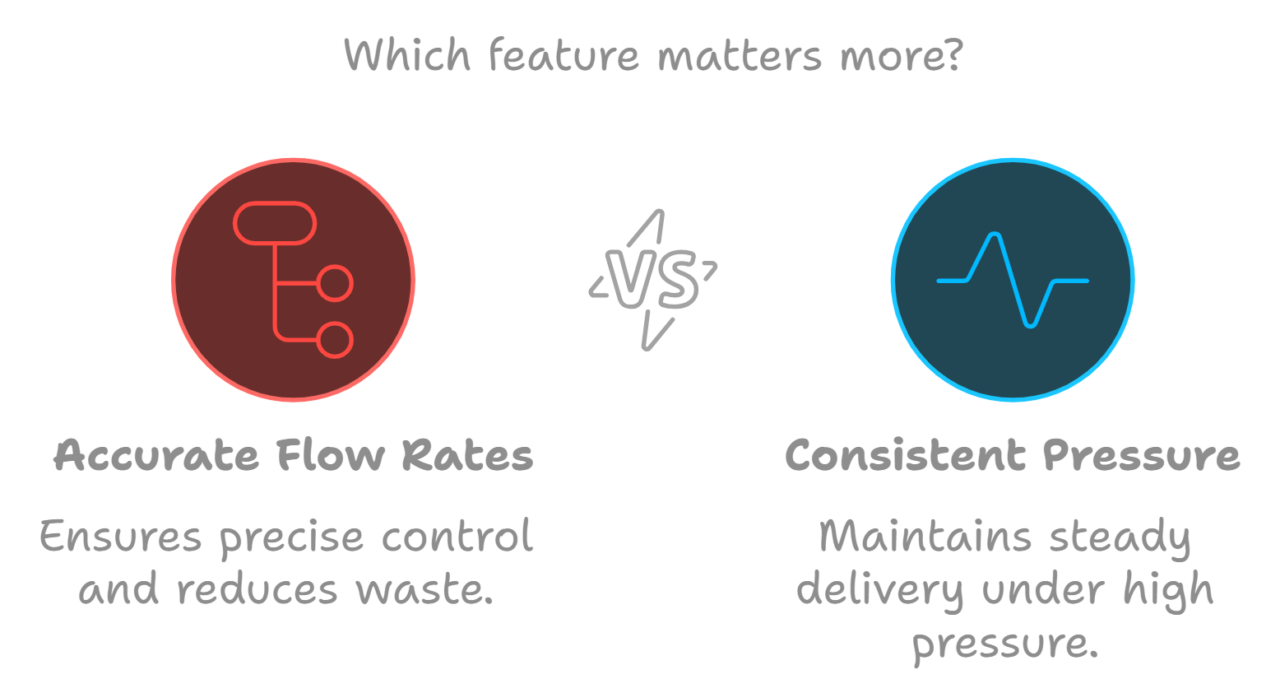

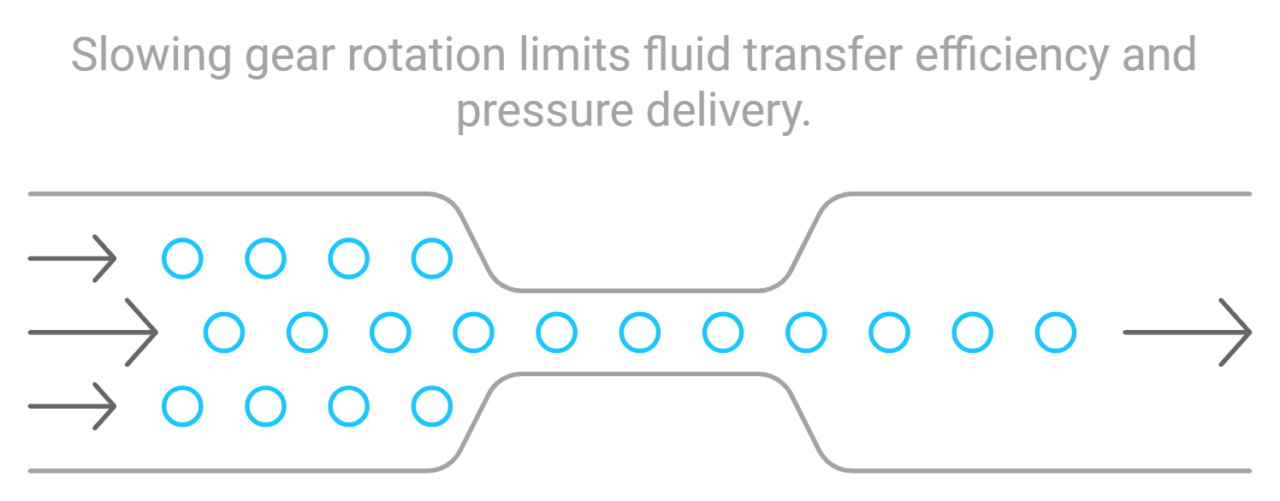

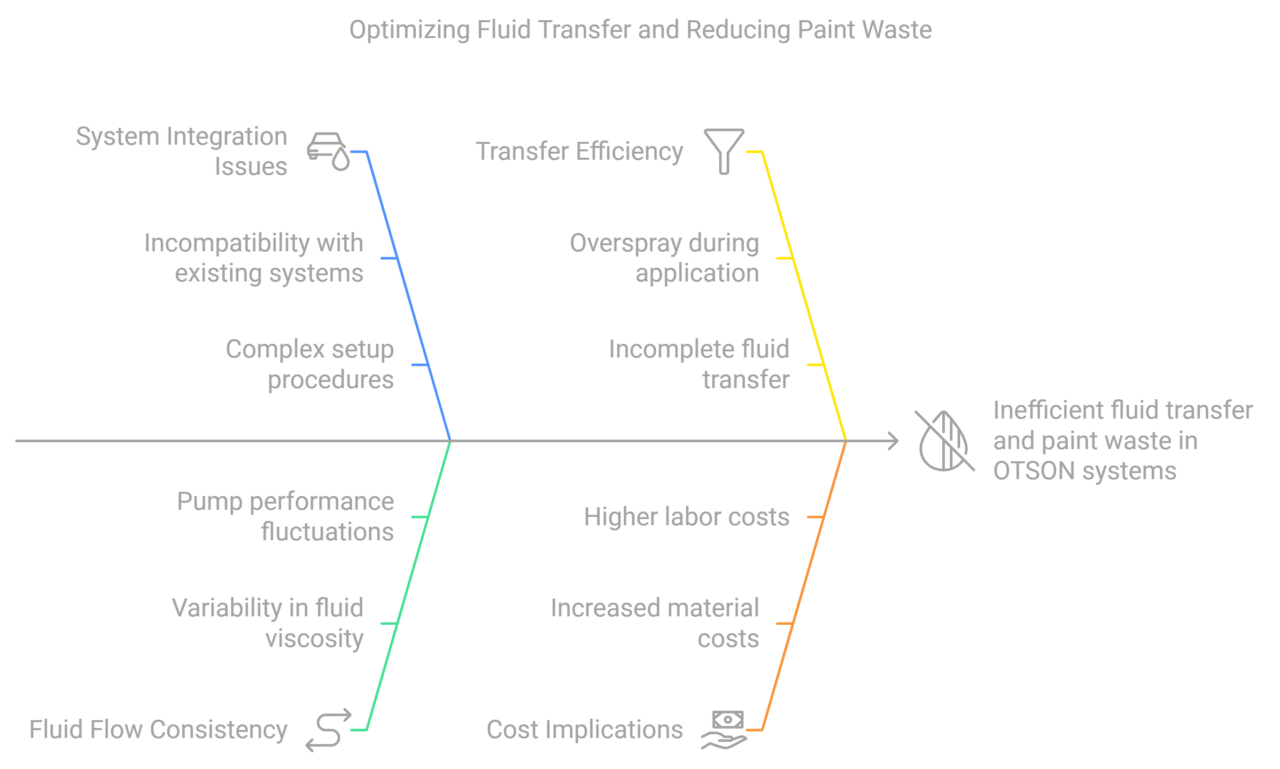

A leading automotive manufacturer was experiencing issues with inconsistent paint thickness on large body panels, leading to high levels of material waste and defects in their production process. Their existing gear pump was nearing the end of its lifecycle, causing flow rate fluctuations and overspray.

Solution:

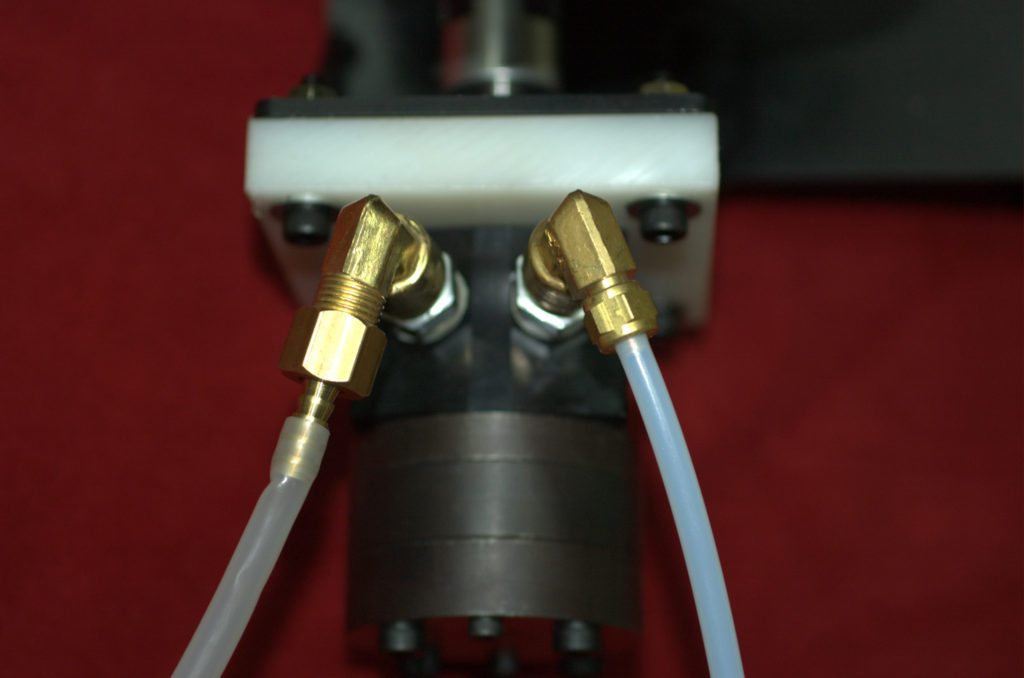

After switching to the OTS-50-V6-CL gear pump, the manufacturer saw immediate improvements in flow control and coating consistency. The OTS-50’s precise flow rate and steady pressure control allowed for a more even application of basecoats and clearcoats on large vehicle panels. The manufacturer integrated the pump into their existing OTSON electrostatic spray system, ensuring seamless compatibility.

Outcome:

- 30% reduction in paint consumption due to improved transfer efficiency.

- 20% decrease in rework and defects, resulting in higher-quality finishes.

- Increased production speed as the pump maintained consistent output even during long production runs.

Testimonial:

“Switching to the OTS-50 gear pump has been a game-changer for our automotive coating line. We’re seeing less paint waste, fewer defects, and more consistent performance overall. The seamless integration with our existing OTSON systems made the upgrade even easier.”

— Production Manager, Leading Automotive Manufacturer

Case Study 2: Aerospace Component Coatings

Challenge:

An aerospace company specializing in the production of aircraft components needed a pump capable of handling high-viscosity, corrosion-resistant coatings. Their previous gear pump struggled to maintain consistent flow, leading to uneven application and potential coating defects, which are critical in the aerospace industry.

Solution:

The company replaced their existing pump with the OTS-50-V3-HT gear pump, specifically designed to handle high-viscosity industrial coatings like epoxies and polyurethanes. The 7:1 gearbox allowed the pump to deliver the necessary torque to move thicker materials at high pressure.

Outcome:

- 25% improvement in coating uniformity, ensuring even distribution on complex aircraft components.

- Significant reduction in material waste, with the pump delivering only the necessary amount of coating.

- Better surface protection, resulting in longer-lasting components and fewer quality control issues.

Testimonial:

“The OTSON gear pump delivered exactly what we needed—consistent, reliable performance even with thick coatings. The improved transfer efficiency and coating quality have been crucial in meeting our aerospace industry standards.”

— Operations Director, Aerospace Manufacturer

Case Study 3: Bicycle Frame Manufacturing

Challenge:

A leading bicycle manufacturer was facing challenges applying different coatings to both aluminum and carbon fiber frames. They required a versatile gear pump capable of switching between waterborne primers and high-viscosity powder coatings.

Solution:

The company opted for the OTS-50-V6-XT gear pump, which could seamlessly handle both low-viscosity and high-viscosity coatings by adjusting the VFD settings on the motor. This allowed for flexible operation and efficient coating application across different frame materials.

Outcome:

- 20% increase in production efficiency, as the OTS-50 pump easily transitioned between different coating types without downtime.

- Consistent finishes across all frame materials, improving product quality and customer satisfaction.

- Lower maintenance costs, with the wear-resistant materials of the OTS-50 pump extending its operational life.

Testimonial:

“OTSON’s OTS-50 gear pump has made a noticeable difference in our production line. We’re able to coat different frame materials more efficiently, with less downtime and improved quality. The durability of the pump means we’re not constantly dealing with repairs.”

— Plant Manager, Bicycle Manufacturer

Case Study 4: Woodworking and Furniture Manufacturer

Challenge:

A high-end furniture manufacturer needed a solution to apply thick lacquers and stains to large surface areas of wooden furniture. Their previous pump struggled to maintain consistent flow, leading to streaks, uneven finishes, and material waste.

Solution:

The company installed the OTS-50-V6-HT pump, designed to handle high-viscosity materials and provide even coverage on wide surfaces. The pump’s precise control ensured that the coatings were applied evenly, resulting in a smooth and high-quality finish.

Outcome:

- 50% reduction in coating defects, leading to a higher-quality final product.

- Reduced material waste, with the pump delivering only the necessary amount of lacquer or stain.

- Higher customer satisfaction due to the improved quality of finishes.

Testimonial:

“We’ve seen a dramatic improvement in our finish quality since installing the OTSON gear pump. The even flow and consistent pressure have made a big difference in the final look of our products, and we’re using less material in the process.”

— Production Supervisor, Furniture Manufacturer

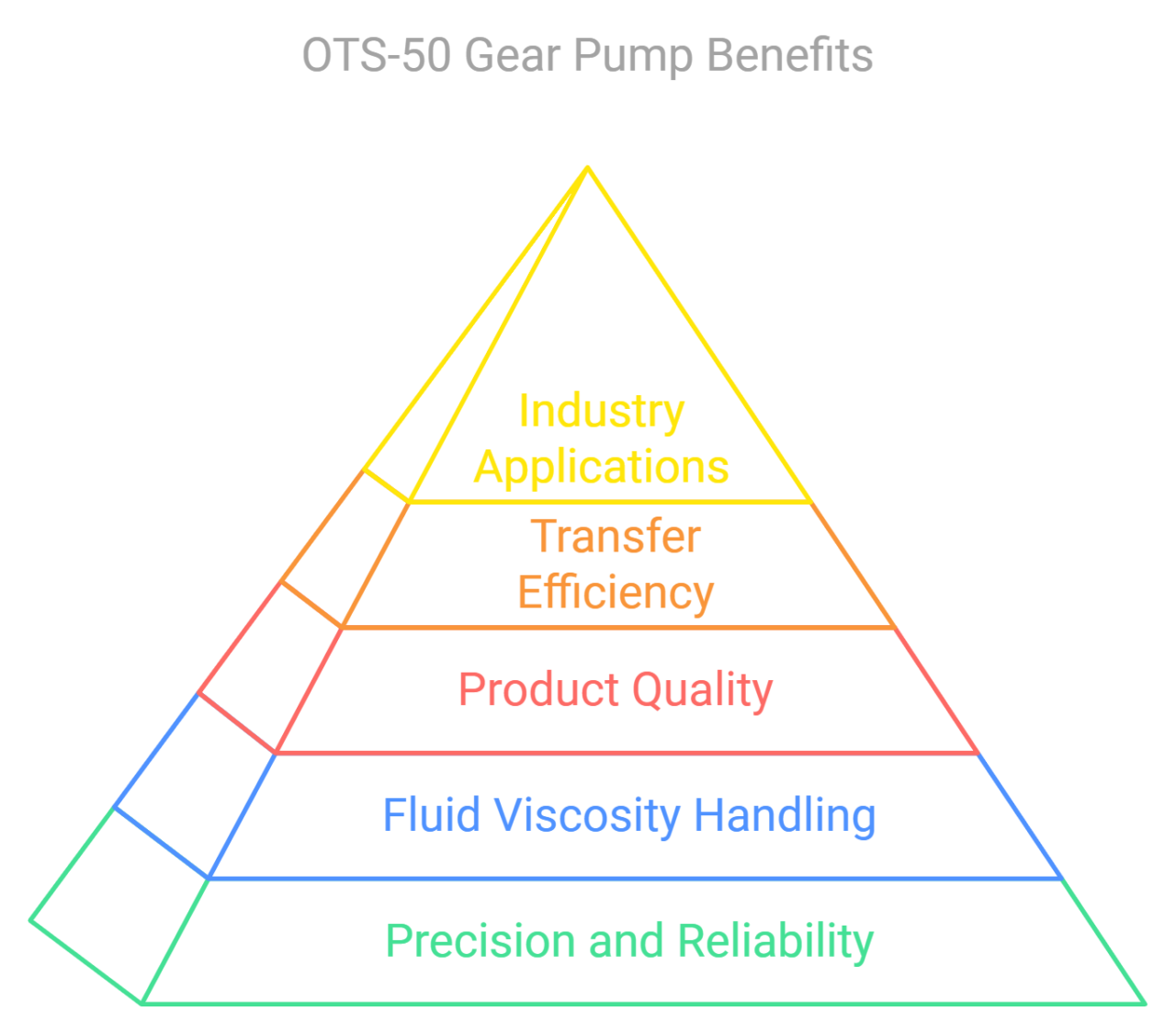

Summary of Key Benefits from Real-World Applications:

- Higher transfer efficiency, reducing material waste and lowering costs.

- Improved product quality, with fewer defects and more uniform finishes.

- Reduced downtime, with less need for maintenance and easier integration with existing systems.

- Versatile handling of different coating types, from low-viscosity waterborne paints to high-viscosity industrial coatings.

- Increased production efficiency, helping customers meet tight deadlines while maintaining quality standards.

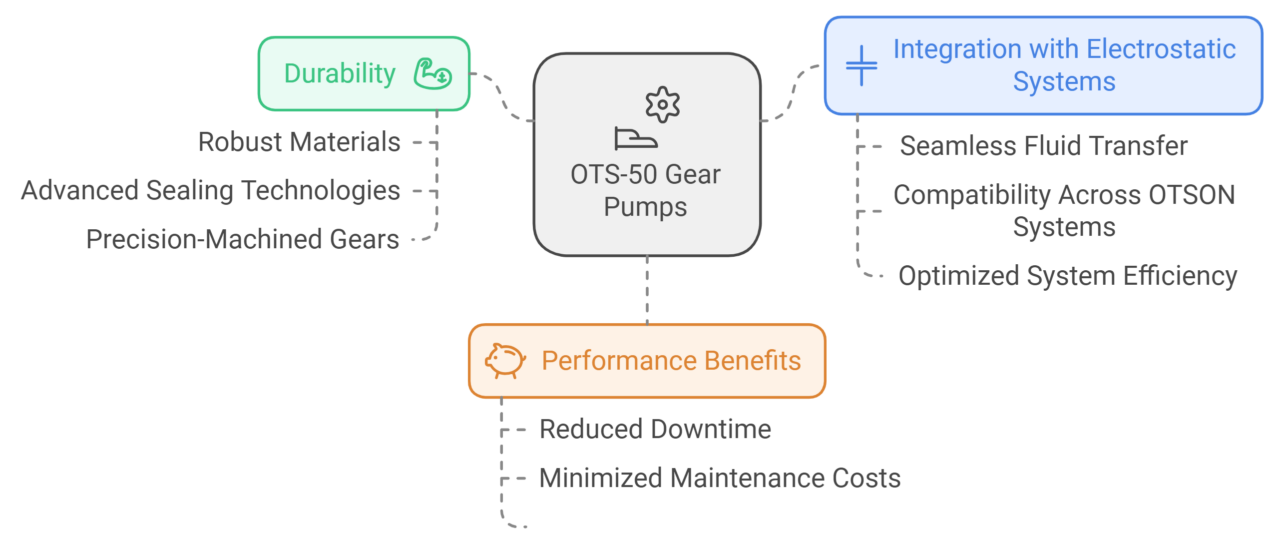

Why These Case Studies Matter:

These examples demonstrate how the OTS-50 Gear Pump Line helps businesses across different industries improve their fluid handling and coating processes. Whether replacing competitor gear pumps or upgrading existing OTSON systems, the OTS-50 series delivers measurable improvements in both performance and cost savings.