Proven Strategies to Reduce Downtime in Your Paint Shop Using OTSON’s Smart Equipment

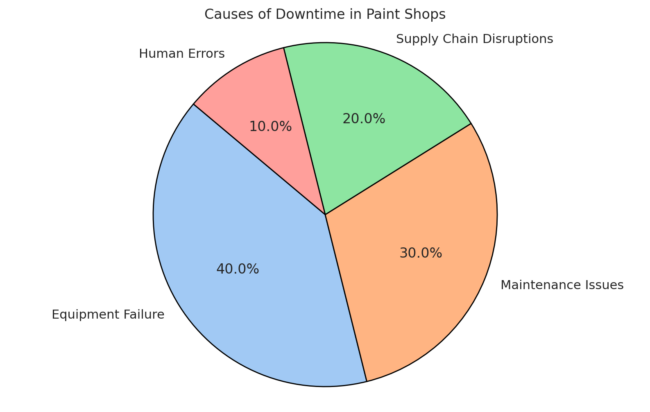

Proven Strategies to Reduce Downtime in Your Paint Shop Using OTSON’s Smart EquipmentTable of Contents Introduction Understanding Downtime in Paint Shops The Impact of Downtime on Operational Efficiency Preventive Maintenance: A Key Strategy Implementing a Preventive Maintenance Plan The Role of OTSON’s Smart Equipment Benefits of Using OTSON’s Smart Equipment Case Studies: Success Stories with