Ultimate Buyer’s Guide to Liquid Electrostatic Spray Coating

Your ultimate go-to resource for everything you need to know about liquid electrostatic spray coating. Master the art and science of the technique and explore how it could revolutionize your business.

- The Science Behind Electrostatic Spray Coating

The fundamental principle behind electrostatic spray coating is the attraction between opposite charges. The paint is atomized and then charged, usually with a negative charge. The workpiece, grounded, acts as the positive pole. The charged paint particles are attracted to the workpiece, ensuring an even and high-quality coating. - Types of Liquid Electrostatic Spray Coating

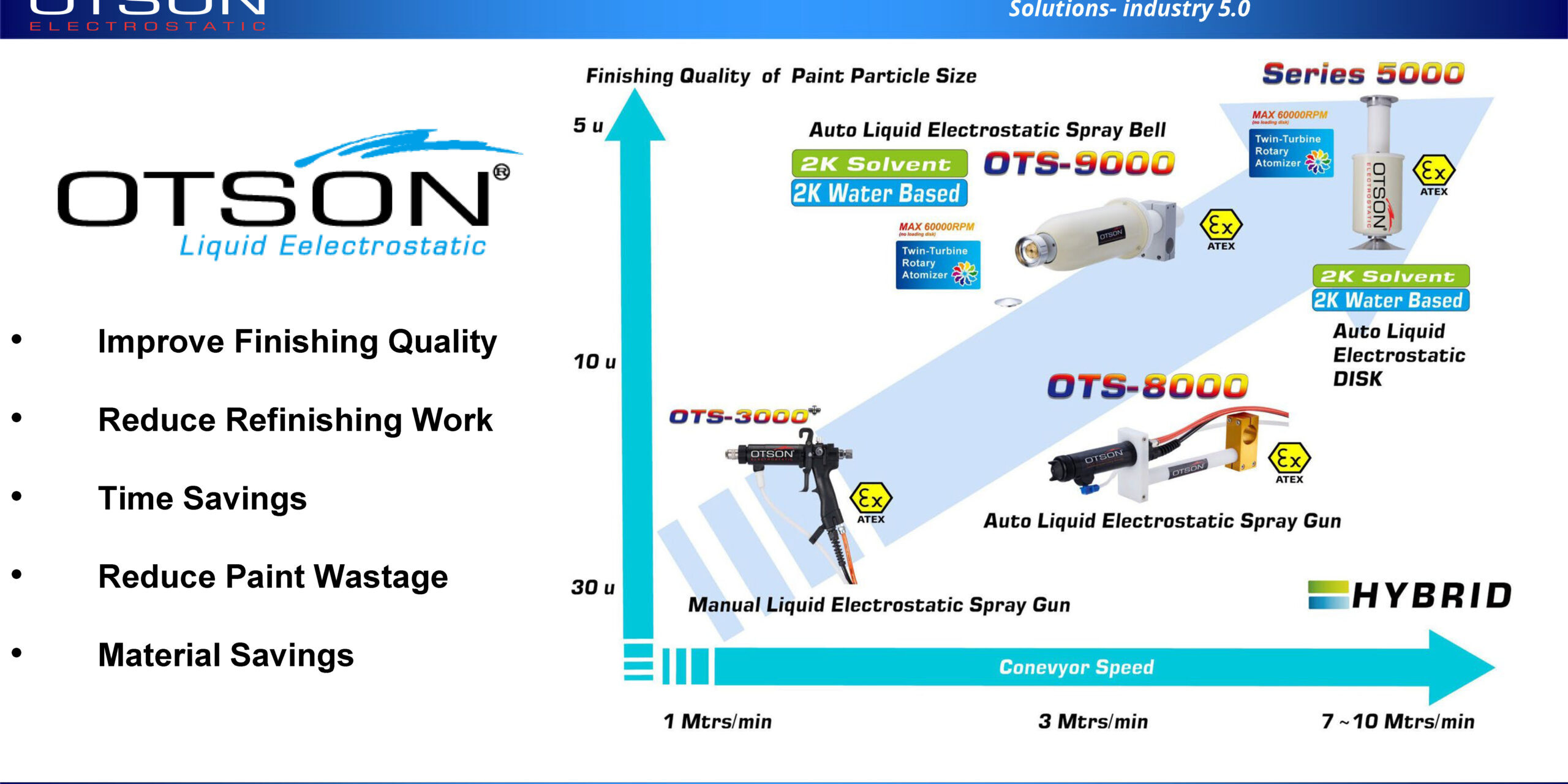

There are different types of liquid electrostatic spray coating techniques, each with its unique attributes. These include air spray, airless spray, and rotary atomization. The choice depends on the specific application and the desired finish. - Benefits of Liquid Electrostatic Spray Coating

Liquid electrostatic spray coating offers numerous benefits over traditional coating methods. These include superior finish quality, improved coating efficiency, reduced overspray, and material savings. In addition, it is a more environmentally friendly option as it reduces VOC emissions. - Application Areas of Electrostatic Spray Coating

Electrostatic spray coating finds application in a variety of industries such as automotive, aerospace, industrial equipment, furniture, and appliances. It is particularly beneficial where precision and high-quality finish are essential. - Essential Equipment for Electrostatic Spray Coating

The equipment for liquid electrostatic spray coating includes a spray gun, a power supply to charge the paint, a paint delivery system, and a grounding system. The choice of equipment depends on the specific application and the type of coating material used. - Choosing the Right Coating Material

Choosing the right coating material is essential for the success of the electrostatic coating process. Factors such as the workpiece material, the desired finish, durability requirements, and environmental conditions play a significant role in the selection process. - Step-by-Step Process of Electrostatic Spray Coating

The electrostatic spray coating process involves several steps, including pre-treatment, coating application, curing, and inspection. Each step is crucial and requires careful execution to ensure a high-quality finish. - Safety Measures in Electrostatic Coating

Safety is paramount in electrostatic coating operations. This includes ensuring proper grounding, using appropriate personal protective equipment, and maintaining a clean and safe work environment. - Impact of Electrostatic Coating on Sustainability

Electrostatic coating is a more sustainable alternative to traditional coating methods. It reduces overspray, resulting in significant material savings and reduced VOC emissions. In addition, it enables the use of water-based and high-solids coatings, further enhancing its environmental credentials. - Cost Analysis of Electrostatic Coating

While the initial investment in electrostatic coating equipment can be high, the benefits in terms of material savings, improved efficiency, and superior finish quality often justify the cost. An accurate cost analysis must consider both the upfront and ongoing costs. - Training and Skills Required for Electrostatic Coating

Operating an electrostatic coating system requires specialized skills and training. This includes understanding the principles of electrostatics, operating the equipment, managing the coating process, and troubleshooting common problems. - Quality Control in Electrostatic Coating

Quality control is essential in electrostatic coating operations. This involves routine inspection of the coated workpieces, regular maintenance of the equipment, and monitoring of the coating process parameters. - Troubleshooting Common Problems

Common problems in electrostatic coating operations can include uneven coating, poor adhesion, and excessive overspray. Understanding the root causes and how to address them is key to maintaining high-quality output. - Future Trends in Electrostatic Coating

With advances in technology, the electrostatic coating is set to become even more efficient and versatile. Future trends include the use of intelligent systems for process control, new materials for coating, and innovative equipment designs. - Key Players in the Electrostatic Coating Market

Several key players dominate the electrostatic coating market. These include iOTSON Paint Shop Technologies, PPG Industries, The Sherwin-Williams Company, and AkzoNobel. Each of these companies has made significant contributions to the development and adoption of electrostatic coating technologies. - Case Studies of Successful Electrostatic Coating Applications

Real-world examples of successful electrostatic coating applications can provide valuable insights. These case studies cover different industries and applications, demonstrating the versatility and effectiveness of the technique.

Electrostatic coating has come a long way since its inception in the 1940s. It was first used during World War II for industrial purposes. With advancements in technology, the process has become more efficient and versatile, finding applications in various industries.

Frequently Asked Questions

1. What is liquid electrostatic spray coating?

Liquid electrostatic spray coating is a process that uses electrically charged particles to apply a liquid coating to a grounded workpiece. This technique enables the coating to adhere more efficiently and uniformly to the object’s surface, leading to a superior finish and efficient use of materials.

2. How does electrostatic spray coating work?

Electrostatic spray coating works based on the principle of opposite charges attracting each other. In this process, the coating material (paint or other liquid) is atomized and electrically charged, typically with a negative charge. The workpiece to be coated is grounded, making it the positive pole. When the charged coating particles are sprayed onto the workpiece, they are attracted to it, ensuring an even and high-quality coating.

3. What are the benefits of liquid electrostatic spray coating?

Liquid electrostatic spray coating offers several benefits. It provides a superior quality finish with excellent uniformity and adherence. It also improves coating efficiency and significantly reduces overspray, resulting in material savings. Moreover, it is an environmentally friendly process, as it reduces Volatile Organic Compound (VOC) emissions.

4. What equipment is needed for electrostatic spray coating?

The essential equipment for liquid electrostatic spray coating includes a spray gun, a power supply to charge the paint, a paint delivery system, and a grounding system. Additional tools and equipment may be needed depending on the specific application and the type of coating material used.

5. How can I ensure a high-quality finish in electrostatic coating operations?

To ensure a high-quality finish in electrostatic coating operations, it is essential to correctly set up and maintain the equipment, choose the right coating material, and carefully control the coating process parameters. Regular inspections and quality control checks are also crucial. In addition, operators must be properly trained and skilled in using the equipment and handling the materials.

6. What are the future trends in electrostatic coating?

Future trends in electrostatic coating include the use of intelligent systems for improved process control, new materials for coating, and innovative equipment designs. Advances in technology will also enable more efficient and versatile electrostatic coating processes, further expanding their applications in various industries.

Conclusion

The liquid electrostatic spray coating offers a combination of efficiency, precision, and high-quality finish that is hard to match. As this Ultimate Buyer’s Guide to Liquid Electrostatic Spray Coating has shown, understanding the process and making informed choices can help businesses harness the full potential of this innovative technique.