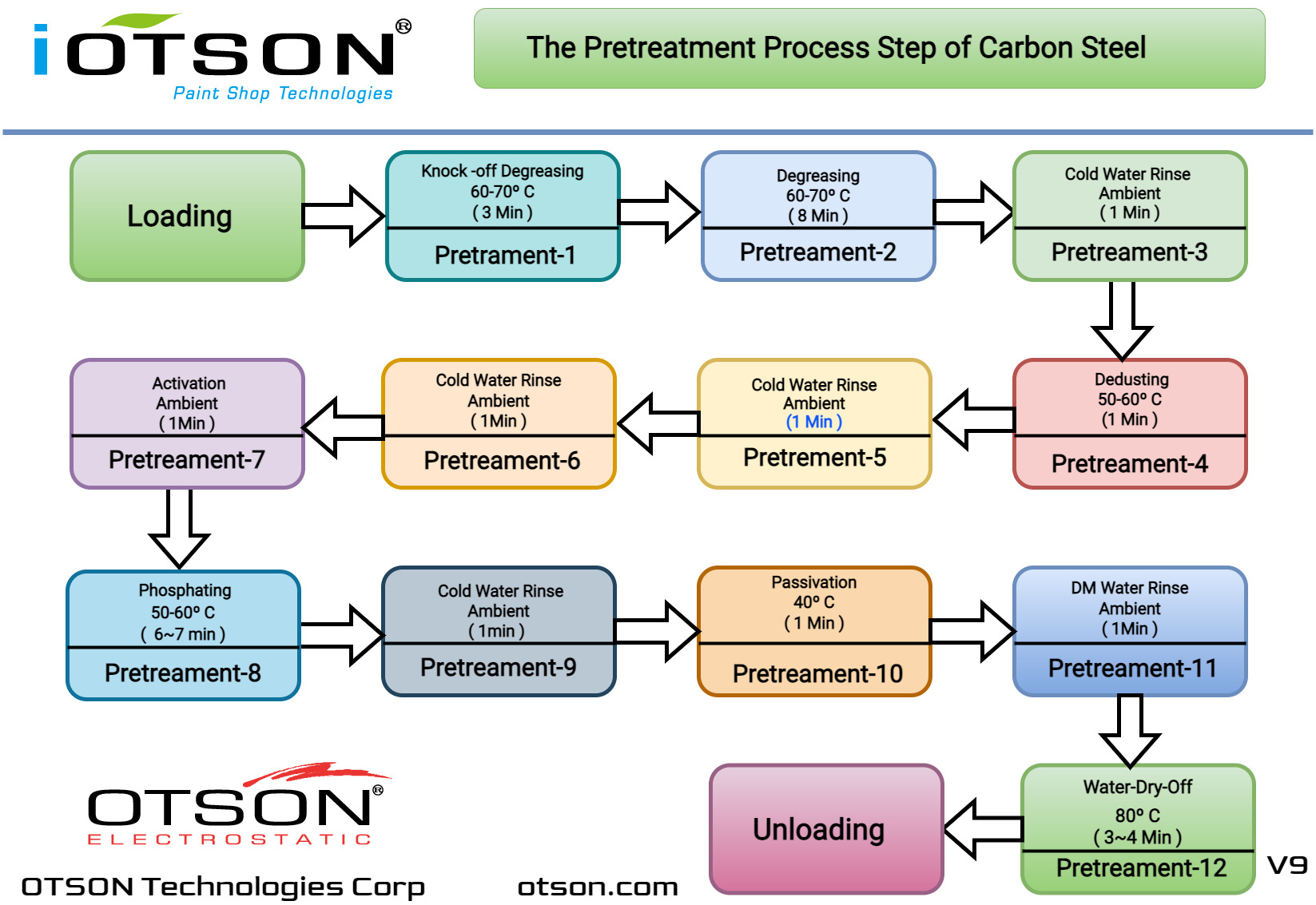

The image shows a section of the pre-treatment line in the IOTSON Paint Shop Technologies facility designed for pre-treating carbon steel components prior to painting. This process ensures that the surface is properly prepared for optimal paint adhesion and corrosion resistance.

The carbon steel components are first loaded onto a conveyor belt and then move through a series of stages. In the first stage, the components are thoroughly cleaned using high-pressure water jets and a degreaser to remove any dirt, oil, or other contaminants from the surface.

Next, the components pass through a series of rinse tanks to remove any remaining cleaning solution. The rinse tanks use a counter-flow system to ensure that the water is continually refreshed, and that any contaminants are removed from the surface of the components.

After rinsing, the components enter the iron phosphate stage where they are treated with an iron phosphate solution to create a thin layer of conversion coating on the surface. This coating provides excellent adhesion for the subsequent layers of paint and also improves corrosion resistance.

Next, the components are rinsed again to remove any excess iron phosphate solution and then dried using hot air blowers before being transferred to the painting line.

The image shows the various stages of the pre-treatment process, including the conveyor belt, cleaning stations, rinse tanks, iron phosphate tank, and drying section. The components can be seen moving along the line, with operators monitoring the process and making adjustments as necessary to ensure optimal results.

Overall, this pre-treatment process ensures that the carbon steel components are properly cleaned, and that a uniform and durable surface is created for optimal paint adhesion and corrosion resistance.