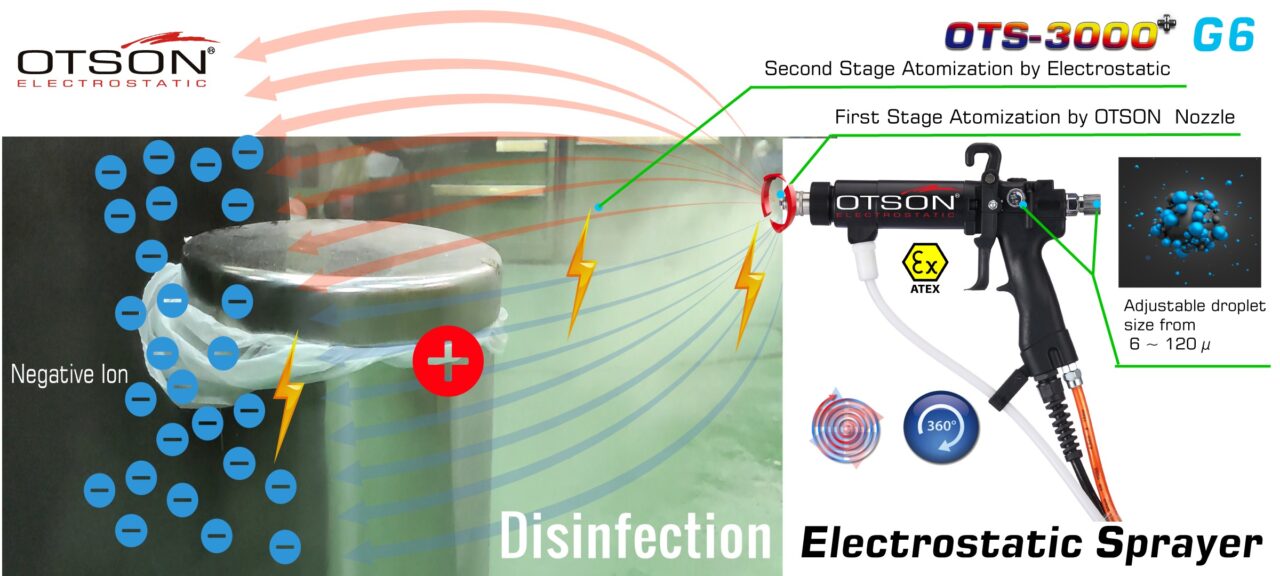

Electrostatic Sprayer-OTSON’s electrostatic technologies offer unsurpassed uniformity in coverage of complex surfaces with high transfer efficiency.

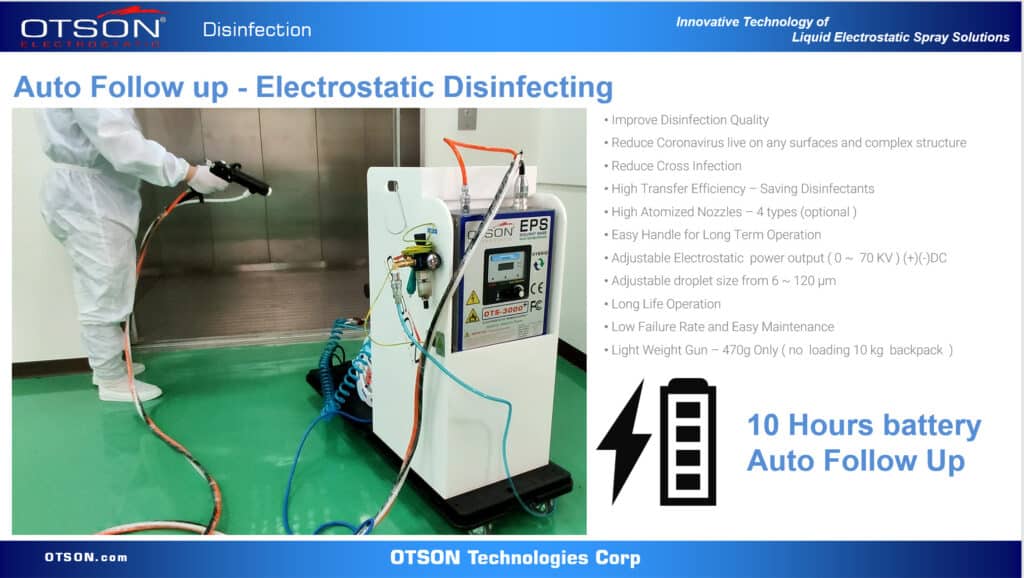

- Improve Disinfection Quality

- Reduce Coronavirus live on plastic and Stainless steel surfaces

- Reduce Cross Infection

- High Transfer Efficiency – Saving Disinfectants

- High Atomized Nozzles – 4 types (optional )

- Easy Handle for Long Term Operation

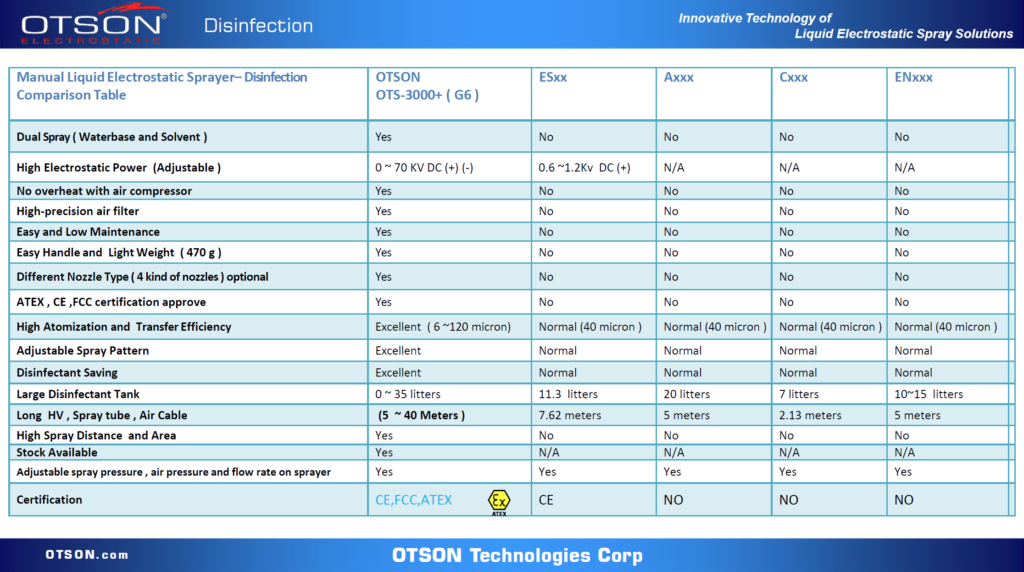

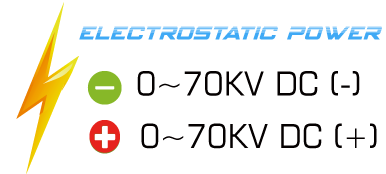

- Adjustable Electrostatic power output ( 0 ~ 70 KV -DC (+) (-) )

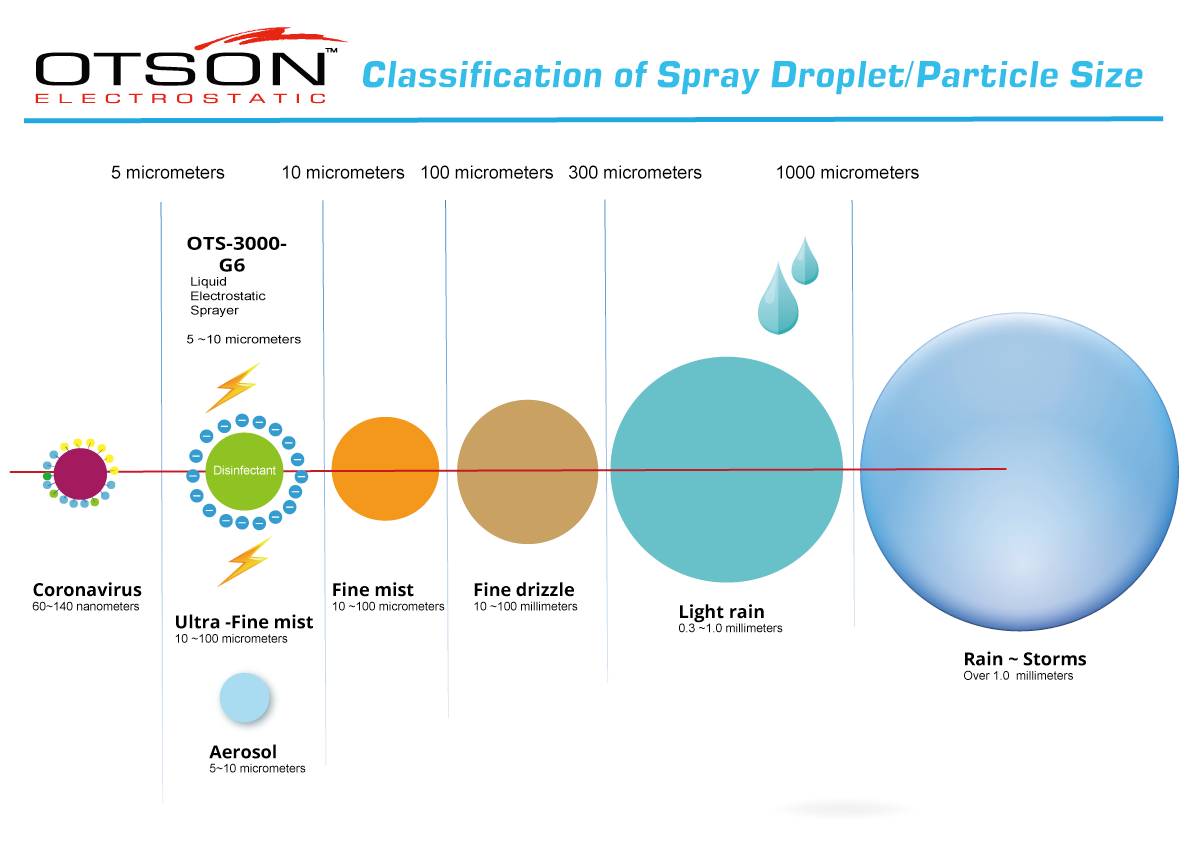

- Adjustable droplet size from 6 ~ 120 μm

- Long Life Operation

- Low Failure Rate and Easy Maintenance

- Light Weight Gun – 470g Only ( no loading 10 kg backpack )

The Benefits of Electrostatic Disinfecting

Electrostatic disinfection is an innovative method that saves time, energy and costs across the board because it presents a more efficient alternative to traditional cleaning techniques and cleaning solution applications. Below are some of the many benefits of using an electrostatic system.

Reduces the time it takes to cover and disinfect all surfaces and hard-to-reach places by 50% compared to conventional methods

- Improves infection control and the spread of viruses such as influenza, MRSA, HIV, and many others

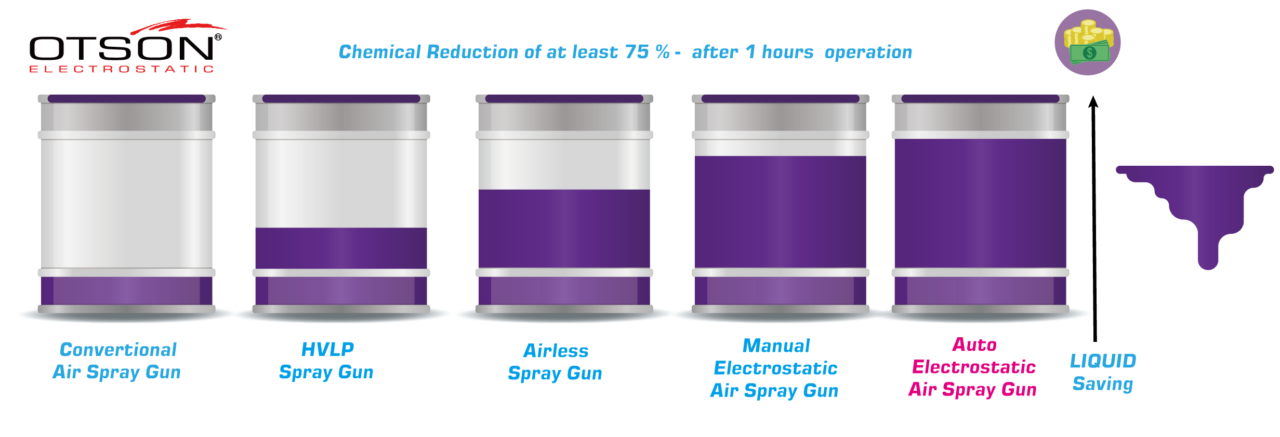

- Applies chemicals in a more efficient, uniform and controlled manner, eliminating the dangers of overuse and reducing the number of chemicals used and waste produced

- Prevents costly financial burdens associated with contagious healthcare infections

- Avoids cross-contamination and the movement of bacteria from one surface to another

- Saves chemical solution costs and those associated with long-term cleaning efforts

The Effective Disinfection of Electrostatic Spray

This cleaning method atomizes cleaning solutions to produce an electrically charged spray able to wrap around surfaces of all types for an even coat. As a chemical exits the electrostatic sprayer, it’s given a negative charge that is attracted to available positive surfaces. The spray attaches to and collects negatively charged unwanted particles, which are then removed from the environment with a specially designed apparatus. Surfaces that are already covered in the cleaning solution will repel the spray, making the method extremely efficient.

Case Study

Disinfectant Consumption : 1 gallon = 3.78 liters

1 Hour: 796.31 m² ( 8571.42 ft² )

Flow Rate : 3.78 liters / 60 min= 0.063 liters x 1000 = 63 cc /min ( 2.13 ounce /min)

Coverage : 796.31 m² / 60 min = 13.27 m² / min ( 142.83 ft²/ min )

Effective Disinfection

360 Degree Spray

Light Weight Electrostatic Sprayer

Save Cost and Disinfectant

Micro Drople Size

Electrostatic Voltage / Current

Electrostatic Power

Multitype Nozzles

Electrostatic Spray - Disinfection Equipment

OTSON Technologies makes use of advanced technology to produce high-quality electrostatic spray equipment for effectively and efficiently clean even the most hard-to-reach surfaces.

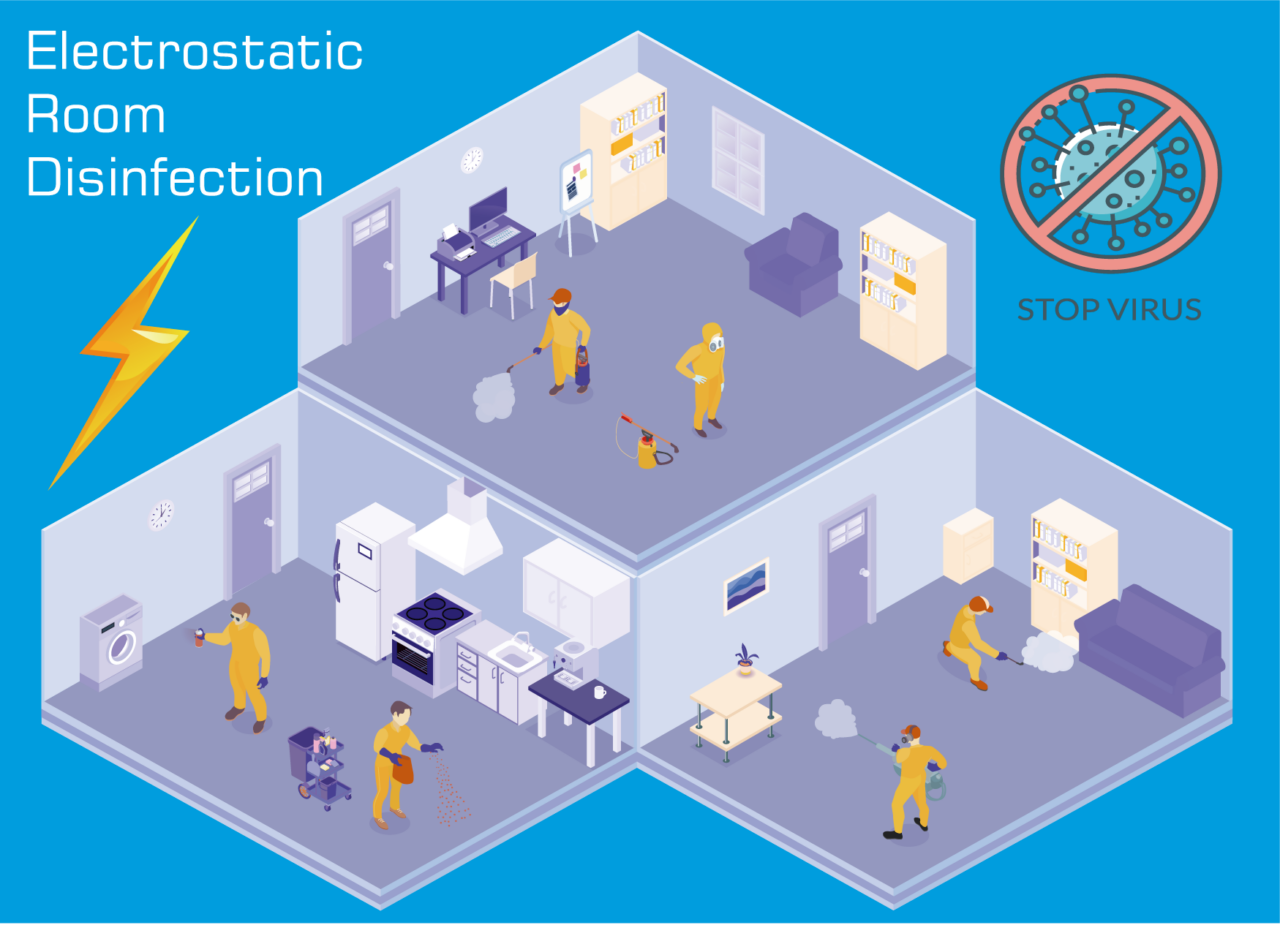

The Electrostatic disinfection equipment is a tool used to apply disinfectants, mold preventative, and sanitizers to 3D surfaces for a 360-degree complete clean. Electrostatic disinfection technology is often used in facilities where mold or bacteria outbreak has been suspected or identified, but it is also a great tool in supplementing the everyday cleaning techniques used in corporate offices, medical and healthcare facilities, schools and universities, commercial kitchens and clean rooms and research and development facilities.

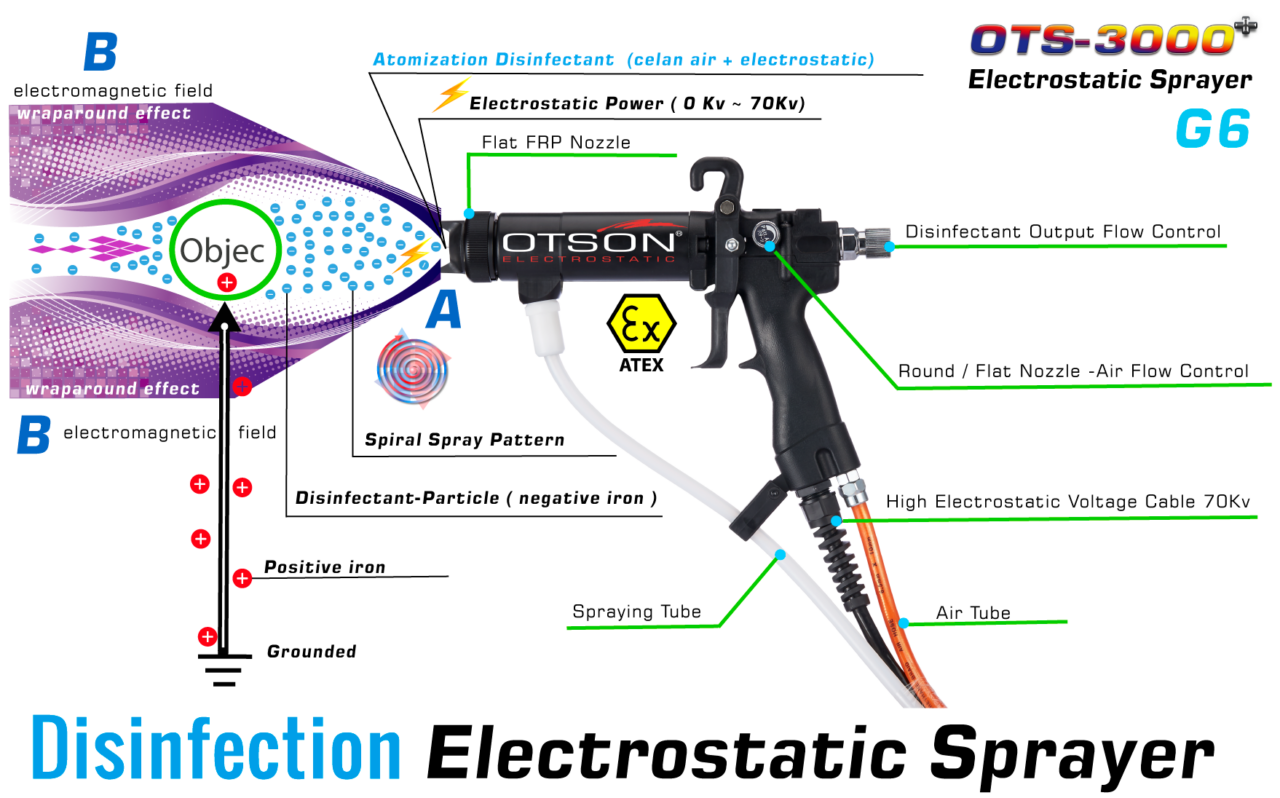

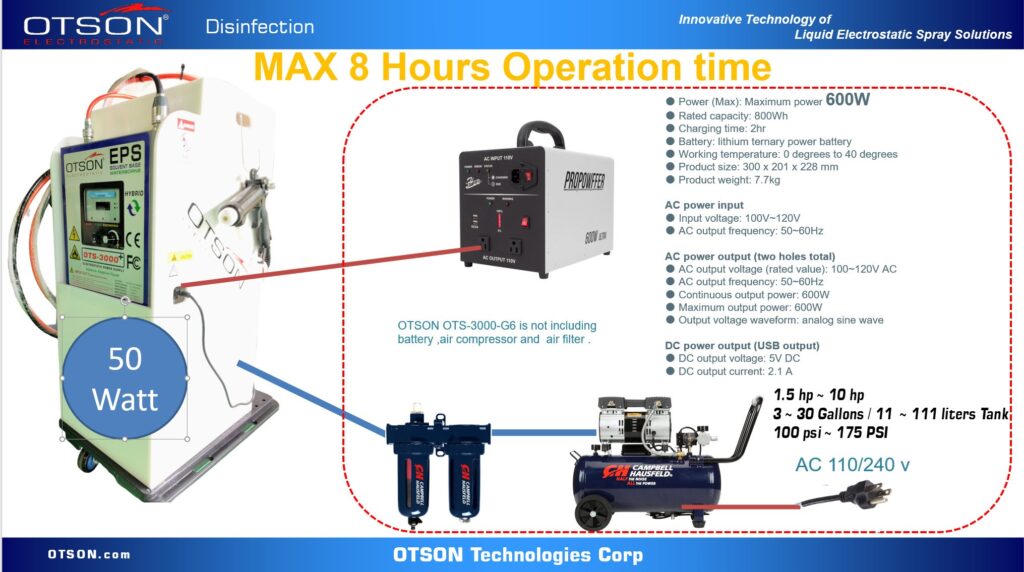

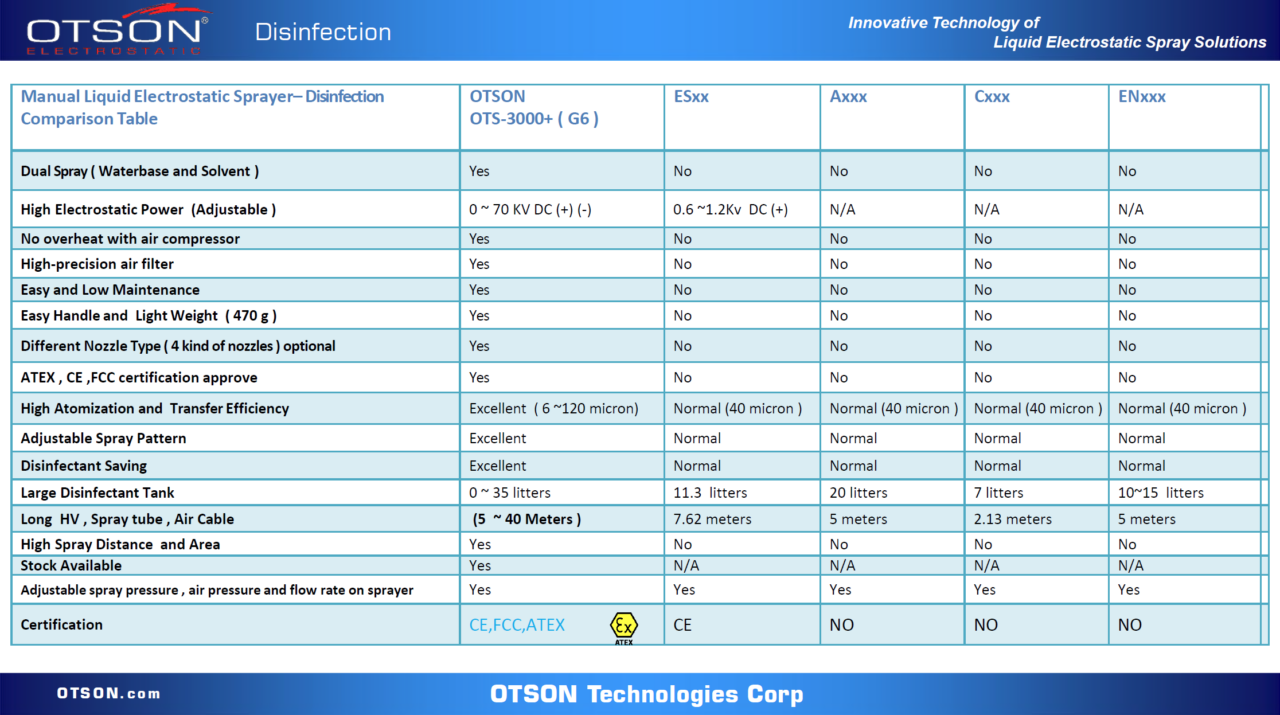

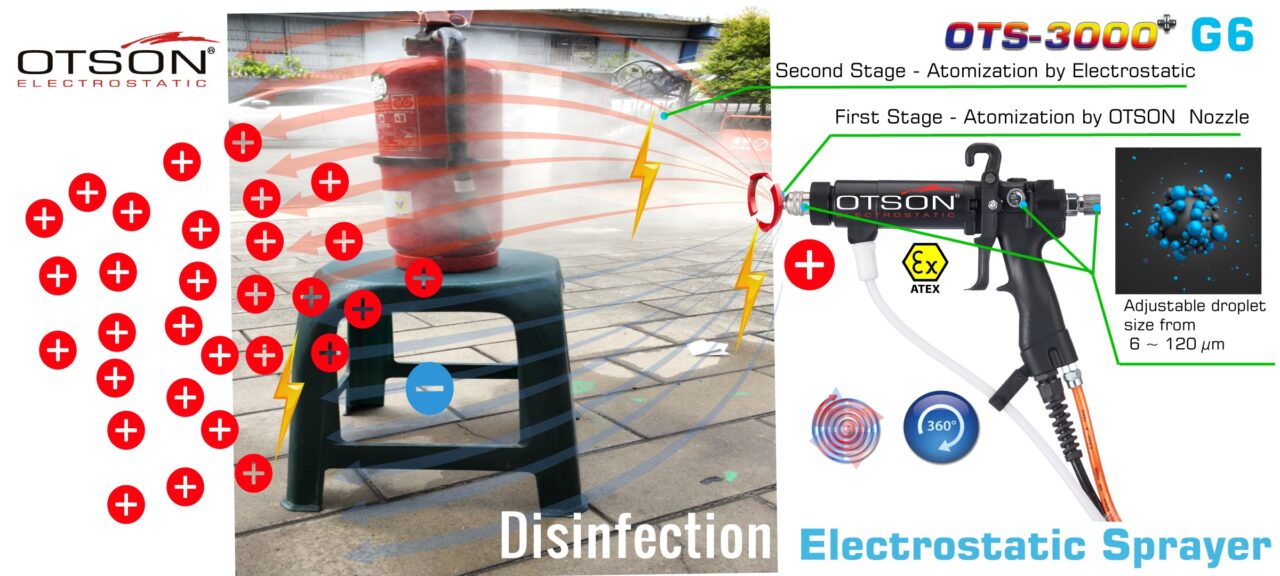

OTS-3000+ Manual Liquid Electrostatic Sprayer-Disinfection-G6 contains the required standard equipment such as an air regulating valve, electrostatic power supply , electrostatic spray gun and Round ( TIN ) nozzle, one set each ( Round ( FRP ) and Flat ( FRP ) nozzle are available for the customer’s option). The above-said electrostatic sprayer in conjunction with the disinfectants tank ,double diaphragm pump, air dryer and air compressor forms one complete set of manual liquid electrostatic spraying equipment for improving disinfection quality and transfer efficiency.

These spiral effect reduces disinfectant-particle velocity. Therefore the disinfectant will be atomized. The technique involves applying a charge, usually positive to the disinfectant material as it is atomized.The positivity charged spray droplets are attracted to any surface; if the object is no earthed, the positivity charged droplets are attracted preferentially to it. Electrostatic spraying exploits the electromagnetic field that arises between two bodies that possess different electrical charges. This field can be demonstrated by field lines (see illustration), where “A“ represents the positivity-charged sprayer, and “B“ the negativity charged item that is to be sprayed. Disinfectant particles are charged in the sprayer and therefore strive to follow the electromagnetic field lines to the item that is to be covered. The electromagnetic field creates a “wraparound“ effect. Consequently, even the sections hidden from the sprayer get coated.

These spiral effect reduces disinfectant-particle velocity. Therefore the disinfectant will be atomized. The technique involves applying a charge, usually negative, to the disinfectant material as it is atomized. The negatively charged spray droplets are attracted to any earthed surface; if the object is earthed, the negatively charged droplets are attracted preferentially to it. Electrostatic spraying exploits the electromagnetic field that arises between two bodies that possess different electrical charges. This field can be demonstrated by field lines (see illustration), where “A“ represents the negatively-charged sprayer, and “B“ the positively charged item that is to be sprayed. Disinfectant particles are charged in the sprayer and therefore strive to follow the electromagnetic field lines to the item that is to be covered. The electromagnetic field creates a “wraparound“ effect. Consequently, even the sections hidden from the sprayer get coated.

This “wraparound“ effect is so powerful that, with some objects, disinfectant spray can be observed to ‘wrap around’.In this way, the purpose of the electrostatic disinfectant is achieved which can offer transfer efficiency up to 95% and minimize the over spraying phenomenon obviously. OTSON is keeping research and developments in electrostatic equipment in last 38 years, the technologies of OTSON electrostatic can now also be used for waterborne / solvent disinfectants

- Schools

- Car

- Bus

- Hospital

- Healthcare

- Gym

- Medical office

- Dental office

- Assisted living facility

- Hotel

- Government Buildings

- First Aide, Fire Department & Police Stations

- Municipal Buildings

- Homes

[tnc-pdf-viewer-iframe file=”https://ai.otson.com/wp-content/uploads/2020/08/ots-3000-manual-liquid-electrostatic-spray-gun-system-disinection-g6-20200806-v80-small.pdf” width=”1280″ height=”800″ download=”true” print=”true” fullscreen=”true” share=”true” zoom=”true” open=”true” pagenav=”true” logo=”true” find=”true” language=”en-US” page=”” default_zoom=”auto” pagemode=””]

%20OTS-3000-G6W-1280x715.jpeg)