Introduction

In the ever-evolving world of paint shop technology, two methodologies have stood out prominently: the traditional spray coating and the more modern liquid electrostatic spray coating. These painting techniques have been the backbone of industries worldwide, including automotive, aerospace, and woodworking. But how do they stack up against each other? In this article, we’ll explore the intricate details of these two techniques, their advantages, disadvantages, and their applications across various industries.

Liquid Electrostatic Spray Coating: An Overview

Liquid electrostatic spray coating is a modern painting technique that uses electrically charged particles to ensure that paint adheres to the target surface. This method offers a myriad of advantages, including enhanced paint transfer efficiency, decreased paint waste, and improved finish quality. It has become a preferred choice in industries that demand high-quality finishes and environmental sustainability.

-

Principles of Liquid Electrostatic Spray Coating

The underlying principle of liquid electrostatic spray coating is the law of attraction between oppositely charged particles. In this case, the paint particles are negatively charged, and the target object is grounded, creating a positive charge. When the paint is sprayed, it seeks the closest grounded object, ensuring an even coating with minimal overspray.

-

Benefits of Liquid Electrostatic Spray Coating

Liquid electrostatic spray coating offers numerous benefits, including higher transfer efficiency, less waste, and a better-quality finish. Additionally, it allows for easier painting of complex shapes and hard-to-reach areas, leading to an overall reduction in labor costs.

-

Applications of Liquid Electrostatic Spray Coating

From automotive body parts to intricate aerospace components, liquid electrostatic spray coating has wide-ranging applications. Its ability to deliver a high-quality finish with increased efficiency makes it a preferred choice in industries where precision and quality are paramount.

-

Traditional Spray Coating: An Overview

Traditional spray coating, also known as conventional spray painting, is a time-tested method that uses air pressure to atomize paint and spray it onto a target surface. Despite being less efficient than electrostatic spray coating, it remains widely used due to its simplicity and lower initial investment.

-

Principles of Traditional Spray Coating

In traditional spray coating, compressed air is used to atomize the paint into tiny droplets that are then sprayed onto the target surface. The method is straightforward, but it results in a significant amount of overspray, leading to wasted material and potential environmental concerns.

-

Benefits of Traditional Spray Coating

Traditional spray coating is easy to use, requires less initial investment, and is compatible with a wide range of coating materials. It’s an excellent option for small-scale operations or for situations where the quality of finish isn’t the top priority.

-

Applications of Traditional Spray Coating

Traditional spray coating is used in various industries, from automotive to furniture manufacturing. Its simplicity and versatility make it a suitable choice for a wide range of applications.

-

Comparing Liquid Electrostatic Spray Coating and Traditional Spray Coating

Let’s delve deeper into the comparison between liquid electrostatic spray coating and traditional spray coating. We’ll look at key factors like efficiency, finish quality, environmental impact, and cost.

-

Efficiency: Liquid Electrostatic vs Traditional

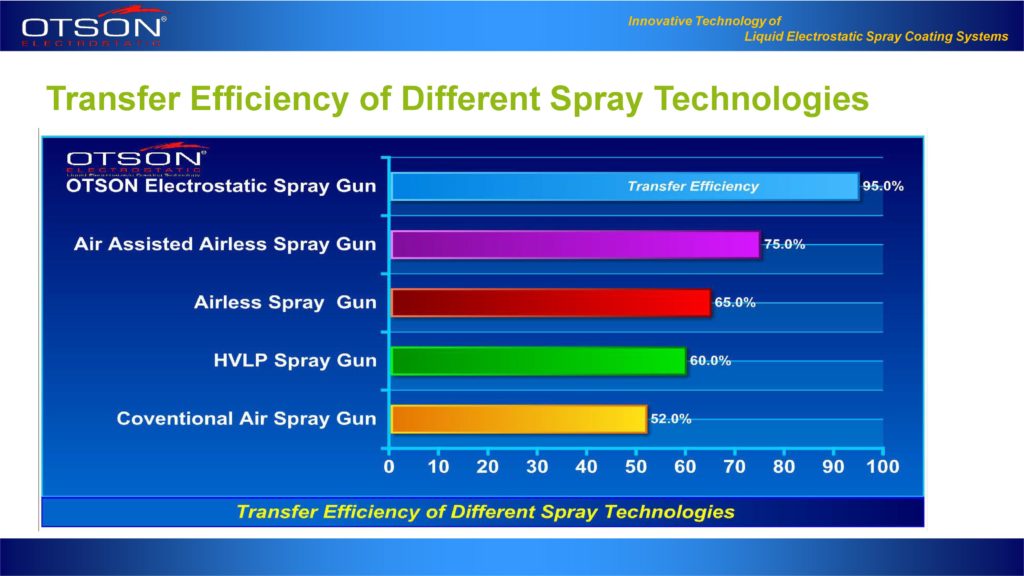

When it comes to efficiency, liquid electrostatic spray coating takes the lead. Its ability to attract paint particles to the target surface significantly reduces overspray and waste, leading to higher transfer efficiency.

-

Quality of Finish: Liquid Electrostatic vs Traditional

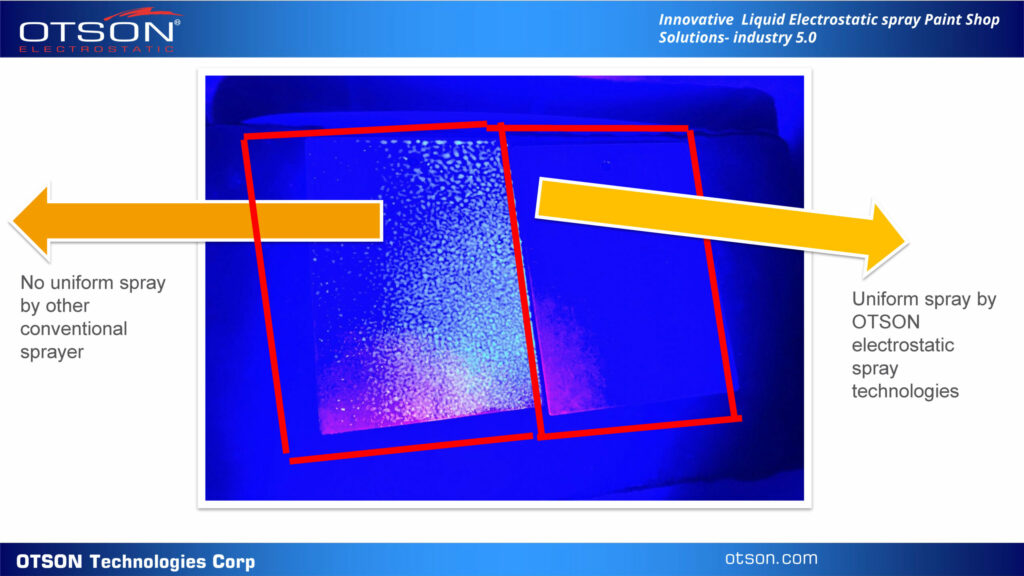

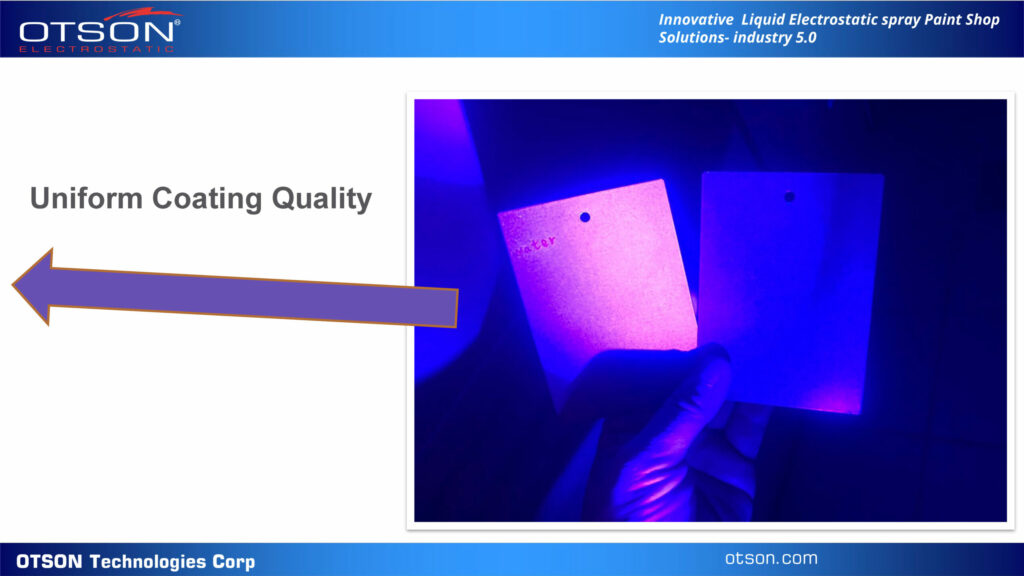

In terms of finish quality, liquid electrostatic spray coating again outperforms traditional spray coating. Its even coating and ability to reach complex areas result in a smoother, more uniform finish.

-

Environmental Impact: Liquid Electrostatic vs Traditional

Liquid electrostatic spray coating offers a more environmentally friendly solution due to its high transfer efficiency and reduced waste. Traditional spray coating, on the other hand, results in significant overspray, which can lead to environmental pollution.

-

Cost: Liquid Electrostatic vs Traditional

While liquid electrostatic spray coating offers numerous benefits, it requires a higher initial investment due to the need for specialized equipment. Traditional spray coating, with its simpler equipment, is less expensive to set up but may incur higher costs in the long run due to increased paint waste.

FAQs

- What is liquid electrostatic spray coating?

Liquid electrostatic spray coating is a painting technique that uses electrically charged particles to ensure that paint adheres to a target surface. This method offers enhanced paint transfer efficiency and improved finish quality. - Why is liquid electrostatic spray coating more efficient than traditional spray coating?

Liquid electrostatic spray coating is more efficient because it reduces overspray and waste. The paint particles are charged and attracted to the grounded object, ensuring a higher transfer rate and a more even coating. - Does liquid electrostatic spray coating have any environmental benefits?

Yes, liquid electrostatic spray coating offers environmental benefits. Due to its high transfer efficiency, there is less overspray and waste, which helps reduce environmental pollution. - Is traditional spray coating still relevant?

Yes, traditional spray coating is still relevant, especially in situations where the initial investment cost needs to be minimized. It is also suitable for small-scale operations or situations where the quality of finish isn’t the top priority. - Which industries benefit the most from liquid electrostatic spray coating?

Industries that demand high-quality finishes and environmental sustainability, such as the automotive and aerospace sectors, benefit the most from liquid electrostatic spray coating. - Is the cost of liquid electrostatic spray coating justified?

While liquid electrostatic spray coating requires a higher initial investment, its benefits such as reduced waste, improved finish quality, and environmental sustainability often justify the cost in the long run, especially for large-scale operations.

Conclusion

In the face of evolving technological advancements, the comparison between liquid electrostatic spray coating and traditional spray coating sheds light on the importance of adapting to more efficient and environmentally friendly painting techniques. While traditional spray coating has its place, the numerous advantages of liquid electrostatic spray coating make it a compelling choice for industries that prioritize quality, efficiency, and sustainability.